Stainless steel 316 polished round bar H11 tolerance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,GB,BS,DIN,API,EN,ASTM

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

2.5-500

Length:

6000

Net Weight:

1-5T

Stainless steel bars,profiles,beams

Product Information:

1) Product feature:

| 1. Product: | Stainless steel 316 polished round bar, 316 stainless steel bright round bar |

| 2. Steel type: | AISI 316 |

| 3. Standard: | ASTM A276, ASTM A484 |

| 4. Diameter: | From Ø1/4'' to Ø16'' ( Diameter: 6mm~400mm ) |

| Such as Ø1'', Ø2'', Ø2.5'', Ø3'', Ø3.5'', Ø4'', Ø4.5'', Ø4.5'', Ø5'',Ø6'', Ø7'', Ø8'' | |

| 5. Length: | 1~ 8meters |

| * Bright: peeled & polished, CNC machined, centreless grinding | |

| 6. Surface: | * Black |

| 7. Diameter tolerance: | H9, H11, H13, K9, K11, K13 etc…as per clients’ request |

| 8. Length tolerance: | 0/+50mm |

| 9. Finishing: | Solution treated |

| 10. Feature of 316L: | Addition of Molybdenum prevents specific forms of corrosion. Also known as "marine grade" |

| 11. Mechanical property: | T.S.: ≥515Mpa, Y.S.: ≥205Mpa, EL: ≥40%, Ruduction of area: ≥50% |

| 12. Application: | Shipbuilding industry, marine shaft, propeller shaft, transmission shaft |

| bolt & nuts, machine-made industry, food industry, paper mill equipment. | |

| 13. Delivery time | Generally within 15~20 days upon receipt the PO, as per the q’ty. |

| 14. Certificate: | ISO, BV, TUV, SGS, mill test certificate |

| 15. Package: | Good quality & fumigated wooden box, which can better protect the bars. ( See pictures below ) |

| 16. Experience:: | * Specialized in producing SS 316L round bar for propeller shaft purpose; |

| * Have a close connection with overseas shipyards , such as Indonesia, Thailand, Philippines, | |

| Singapore, Brazil, Canada etc., so have much experience in this field. |

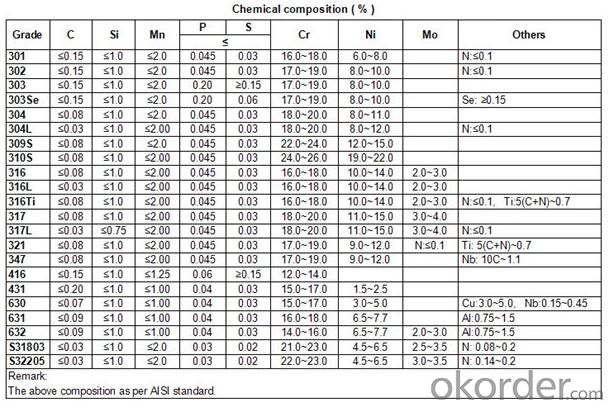

2) Chemical composition:

| Grade | Standard | C | Si | Mn | P | S | Cr | Ni | Mo |

| 316 | ASTM A276 | ≤0.08 | ≤1.0 | ≤2.00 | ≤0.045 | ≤0.03 | 16.0~18.0 | 10.0~14.0 | 2.0~3.0 |

Product Size Detail:

| Main operation | Main steel grade | Available size(mm) | Monthly capacity(mt) | Length(mm) | ||

| OEM | Stainless steel | 40~500 | 1500 | 4000~8000 | ||

| Hot | 303 303Cu 304/L 310S 316/L 321 416 420 | 12 ~200 | 3000 | 4000~7000 | ||

| 17-4PH WLA510 | ||||||

| ST Bar | 321 304/L 316/L 310S 17-4PH WLA510 | 19~110 | 2000 | 4000~7000 | ||

CD Bar | Round bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | |

| Square bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| Hex bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| CG Bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | ||

Specificate:

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q: Can stainless steel bars be used in automotive exhaust systems?

- Yes, stainless steel bars can be used in automotive exhaust systems. Stainless steel is a popular material choice for exhaust systems due to its excellent corrosion resistance, durability, and high-temperature strength. It can withstand the harsh conditions and extreme temperatures associated with exhaust gases, making it a suitable and long-lasting option for automotive exhaust systems.

- Q: What are the different types of stainless steel bars used in architectural railing systems?

- There are several types of stainless steel bars that are commonly used in architectural railing systems. The most common types include: 1. Round bars: These are solid cylindrical bars that are often used for their aesthetic appeal. They are available in various diameters and are often used for handrails or grab bars. 2. Square bars: These bars have a square cross-section and are often used for their modern and clean look. They are commonly used in applications such as balusters or posts in railing systems. 3. Flat bars: These bars have a rectangular cross-section and are often used for their versatility and ease of installation. They can be used for various components in railing systems, including top rails, bottom rails, or even infill panels. 4. Hollow bars: These bars have a hollow center and are often used for their lightweight and cost-effective properties. They are commonly used for infill panels or as spindles in railing systems. 5. Slotted bars: These bars have slots cut along their length, allowing for increased airflow and visibility. They are often used in applications such as glass railing systems or as infill panels. It is important to note that the type of stainless steel used for these bars can vary, with the most common grades being 304 and 316. The choice of stainless steel grade depends on factors such as the environment, corrosion resistance requirements, and budget. Overall, the selection of the stainless steel bar type depends on the specific architectural railing system design, functionality, and aesthetic preferences.

- Q: Can stainless steel bars be used in the mining manufacturing industry?

- Yes, stainless steel bars can be used in the mining manufacturing industry. Stainless steel is highly durable and resistant to corrosion, making it ideal for use in harsh mining environments. It is commonly used for various applications in the mining industry, including structural support, machinery components, and equipment parts, due to its strength and resistance to wear and tear.

- Q: Can stainless steel bars be used in the food and beverage industry?

- Certainly, the food and beverage industry can utilize stainless steel bars. This industry frequently selects stainless steel for its outstanding ability to resist corrosion, its durability, and its hygienic properties. Stainless steel bars serve various purposes, including the formation of structures, the creation of shelving units, the manufacturing of food processing equipment, and the construction of countertops and work surfaces. The exceptional resistance to rust and staining make stainless steel bars an ideal choice for contact with food and beverages, as they do not taint or modify the taste or quality of the products. Furthermore, stainless steel is simple to clean and maintain, which is vital in an industry where cleanliness and sanitation reign supreme. In general, stainless steel bars are widely embraced and employed in the food and beverage industry due to their dependability, safety, and suitability for handling and processing food.

- Q: What are the different types of surface finishes for stainless steel bars?

- There are several types of surface finishes for stainless steel bars, including mill finish, brushed finish, polished finish, and satin finish. The mill finish is the standard finish and has a dull appearance. Brushed finish creates a textured look with parallel lines. Polished finish provides a mirror-like shine, while satin finish offers a smooth, matte appearance.

- Q: What are the applications of stainless steel bars in the oil refining industry?

- Stainless steel bars have a wide range of applications in the oil refining industry due to their unique properties and characteristics. Here are some of the key applications: 1. Heat exchangers: Stainless steel bars are commonly used in the construction of heat exchangers due to their excellent heat resistance and corrosion resistance properties. Heat exchangers are essential in the oil refining process for transferring heat from one fluid to another, and stainless steel bars ensure the durability and longevity of these components. 2. Piping systems: Stainless steel bars are extensively used in the fabrication of piping systems within the oil refining industry. These bars provide high strength and resistance to corrosion, making them suitable for transporting various petroleum products and chemicals. They also have excellent weldability, ensuring the integrity of the piping network. 3. Storage tanks: Stainless steel bars are utilized in the construction of storage tanks for storing crude oil, refined products, and chemicals. These bars offer superior resistance to corrosion and oxidation, preventing contamination and ensuring the longevity of the tanks. Stainless steel tanks are also easier to maintain and have a longer service life compared to other materials. 4. Pressure vessels: Stainless steel bars find applications in the manufacturing of pressure vessels used in oil refining processes. These vessels are designed to store and handle high-pressure fluids, and stainless steel bars provide the necessary strength and corrosion resistance for safe operation. 5. Valves and fittings: Stainless steel bars are commonly used in the production of valves, fittings, and other fluid control components used in oil refining. These bars offer excellent resistance to corrosion and erosion, ensuring the reliability and longevity of these critical components. 6. Catalyst support grids: Stainless steel bars are employed in the construction of catalyst support grids used in various refining processes. These grids provide stability and support to catalyst materials, enabling efficient chemical reactions. Stainless steel bars are preferred due to their high-temperature resistance and resistance to chemical attack. Overall, stainless steel bars play a vital role in the oil refining industry by ensuring the integrity, durability, and efficiency of various equipment and components. Their exceptional resistance to corrosion, high temperatures, and chemicals make them an ideal choice for applications where reliability and longevity are paramount.

- Q: How do you determine the size and length of a stainless steel bar?

- Determining the size and length of a stainless steel bar can be accomplished by following a few straightforward procedures. 1. Diameter measurement: Utilize a caliper or ruler to gauge the diameter of the stainless steel bar. Ensure that you measure at the widest point, as dimensions can vary along the bar's length. 2. Length measurement: Employ a measuring tape or ruler to ascertain the length of the stainless steel bar. Measure from one end to the other, excluding any threaded or chamfered sections if applicable. 3. Specification verification: If accessible, refer to the manufacturer's specifications or product information to determine the size and length of the stainless steel bar. These specifications often offer precise details regarding dimensions and tolerances. 4. Seek professional assistance or reference guide: If uncertain about the accurate measurement or determination of the size and length of a stainless steel bar, it is advisable to consult a professional or consult a reliable reference guide. They can provide guidance and aid in accurately determining the bar's dimensions. Remember, stainless steel bars can take on various shapes and forms, such as round, square, or hexagonal. The measuring technique may slightly differ based on the specific shape, but the aforementioned steps generally assist in determining the size and length of a stainless steel bar.

- Q: Can stainless steel bars be used in heat exchanger applications?

- Yes, stainless steel bars can be used in heat exchanger applications. Stainless steel is a popular material choice for heat exchangers due to its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It is particularly suitable for applications that involve corrosive fluids or environments. Stainless steel bars can be fabricated into various shapes and sizes to meet the specific requirements of the heat exchanger design. Their durability and resistance to oxidation make them a reliable choice for heat transfer applications, ensuring long-term performance and efficiency.

- Q: What are the different types of stainless steel bars used in sports equipment?

- There are various types of stainless steel bars used in sports equipment, including 303, 304, and 316 grades. These bars are chosen for their corrosion resistance, durability, and strength, making them ideal for applications such as weightlifting bars, bicycle frames, and hockey sticks.

- Q: What are the different types of stainless steel bar finishes?

- There are several types of stainless steel bar finishes, including brushed, polished, satin, and mill finishes.

Send your message to us

Stainless steel 316 polished round bar H11 tolerance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords