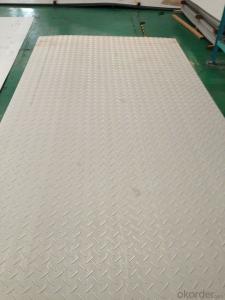

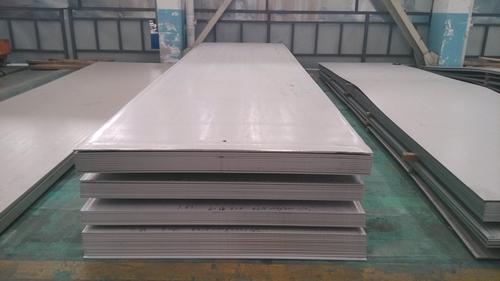

Stainless Steel 304 sheet with innovative technology

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: How do you prevent oxidation in stainless steel pipes?

- Preventing oxidation in stainless steel pipes can be achieved through several methods. One way to effectively prevent oxidation is by applying a protective coating or finish on the surface of the pipes. Various types of coatings, including paints, epoxy, or polyurethane, can serve as barriers that prevent oxygen from coming into contact with the stainless steel, thus reducing the risk of oxidation. Furthermore, keeping the pipes clean and well-maintained is crucial in preventing oxidation. It is essential to eliminate any accumulated dirt, debris, or corrosive substances from the surface of the pipes. This can be accomplished using mild detergents or specialized cleaning agents specifically designed for stainless steel. Ensuring proper ventilation in the installation area is another preventive measure. Sufficient ventilation helps minimize the presence of moisture or humidity, which can accelerate the oxidation process. Additionally, keeping the pipes dry and avoiding prolonged exposure to water or moisture is vital in preventing oxidation. Lastly, selecting the appropriate grade of stainless steel for the intended application is important. Different grades of stainless steel offer varying levels of resistance to oxidation. For instance, austenitic stainless steel grades like 304 and 316 are highly resistant to oxidation and are commonly used in applications where corrosion resistance is crucial. In conclusion, employing a combination of preventive measures, such as protective coatings, regular cleaning, proper ventilation, and selecting the appropriate stainless steel grade, can effectively prevent oxidation in stainless steel pipes.

- Q: Can stainless steel pipes be used for wastewater pumping stations?

- Yes, stainless steel pipes can be used for wastewater pumping stations. Stainless steel pipes are known for their durability, corrosion resistance, and long lifespan, making them an excellent choice for wastewater applications. Wastewater pumping stations often deal with corrosive and abrasive fluids, and stainless steel pipes are capable of withstanding these harsh conditions without deteriorating or causing contamination. Additionally, stainless steel pipes are easy to clean and maintain, which is crucial for wastewater systems. Overall, stainless steel pipes are a reliable and suitable option for wastewater pumping stations.

- Q: What does "stainless steel pipe 201304" mean?

- 201 stainless steel has a certain acid, alkali resistance, high density, polishing, no bubbles, no pinhole and other features, is the production of various watchcase, strap, cover, high-quality materials. Mainly used for decorative pipes, industrial pipes, and some shallow stretch products. The product belongs to high manganese, low nickel stainless steel, nickel content is low, poor corrosion resistance, in all kinds of desktop, countertops, kitchenware, and outdoor decoration projects and urban decoration industry and high-end household products, a larger amount.

- Q: Are stainless steel pipes suitable for food storage facilities?

- Stainless steel pipes are a perfect fit for food storage facilities. The food industry widely embraces stainless steel due to its many advantageous properties. Firstly, stainless steel's resistance to corrosion is crucial in food storage facilities where exposure to moisture and various food products is common. This resistance guarantees that the pipes will not rust or deteriorate over time, thus preventing any potential contamination of the stored food. Furthermore, stainless steel pipes are easy to clean and maintain, making them the ideal choice for food storage facilities that must comply with strict hygiene standards. The smooth and non-porous surface of these pipes prevents the buildup of bacteria, ensuring that the stored food remains safe and uncontaminated. Stainless steel is also a non-reactive material, meaning it does not release any harmful substances into the food. This is particularly important in food storage facilities, as it guarantees the preservation of the integrity and quality of the stored food products. Additionally, stainless steel pipes possess excellent strength and durability, enabling them to withstand the high pressures and temperature fluctuations commonly encountered in food storage facilities. This ensures that the pipes will not fail or break, providing a dependable and long-lasting solution. To conclude, stainless steel pipes are highly suitable for food storage facilities due to their resistance to corrosion, ease of cleaning, non-reactive nature, and strength. They create a safe and hygienic environment for storing food, thereby ensuring the preservation of the integrity and quality of the stored products.

- Q: Are stainless steel pipes suitable for geothermal applications?

- Yes, stainless steel pipes are suitable for geothermal applications. Geothermal systems involve the extraction of heat from the earth's natural geothermal energy, which often requires the transportation of hot fluids such as water or steam. Stainless steel pipes are an excellent choice for this purpose due to their high strength, corrosion resistance, and ability to withstand high temperatures. They are able to withstand the harsh conditions of geothermal environments, including the presence of acidic or corrosive fluids, and are less likely to degrade over time compared to other materials. Additionally, stainless steel pipes offer excellent thermal conductivity, ensuring efficient heat transfer in geothermal applications. Overall, stainless steel pipes are a reliable and durable option for geothermal systems.

- Q: Are stainless steel pipes resistant to intergranular corrosion?

- Yes, stainless steel pipes are resistant to intergranular corrosion.

- Q: Does stainless steel pipe belong to hardware?

- It belongs to me. Stainless steel pipe belongs to the category of hardware in the steel, and stainless steel pendants, flat iron is more hardware. All belong to steel alloy.

- Q: Mirror stainless steel tube 60*60 how much is one meter?

- Examples are stainless steel 63 round tubes, solid thickness 0.82 stainless steel tubes, single support 6 meters long, weight (63-0.82) *0.82*0.02491*6=7.62kg, a six meter long 63 round tube, thickness 0.82, theoretical weight is 7.62kg;

- Q: How do you prevent stress corrosion cracking in stainless steel pipes?

- One way to prevent stress corrosion cracking in stainless steel pipes is to ensure proper material selection. Using stainless steel grades that are resistant to stress corrosion cracking, such as duplex or super duplex stainless steel, can significantly reduce the risk. Additionally, maintaining a suitable environment by controlling temperature, pH levels, and exposure to corrosive substances can also help prevent stress corrosion cracking. Regular inspection and maintenance, including cleaning and passivation, can further enhance the integrity and durability of stainless steel pipes, minimizing the chances of stress corrosion cracking.

- Q: Can stainless steel pipes be used for agricultural irrigation systems?

- Indeed, agricultural irrigation systems can utilize stainless steel pipes. With its exceptional durability and resistance to corrosion, stainless steel proves to be an appropriate material for a wide range of purposes, including agricultural irrigation. Its remarkable ability to withstand rust and corrosion, even when faced with moisture, chemicals, and fertilizers commonly employed in irrigation systems, is well-known. Furthermore, stainless steel pipes possess the capability to endure high-pressure water flow, enabling them to efficiently deliver water to crops. Notably, stainless steel is environmentally conscious, being entirely recyclable, which renders it a sustainable option for agricultural irrigation systems.

Send your message to us

Stainless Steel 304 sheet with innovative technology

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords