SScaffolding Frame Accessoris Lock pin

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding Lock Pin Scaffold Accessoris

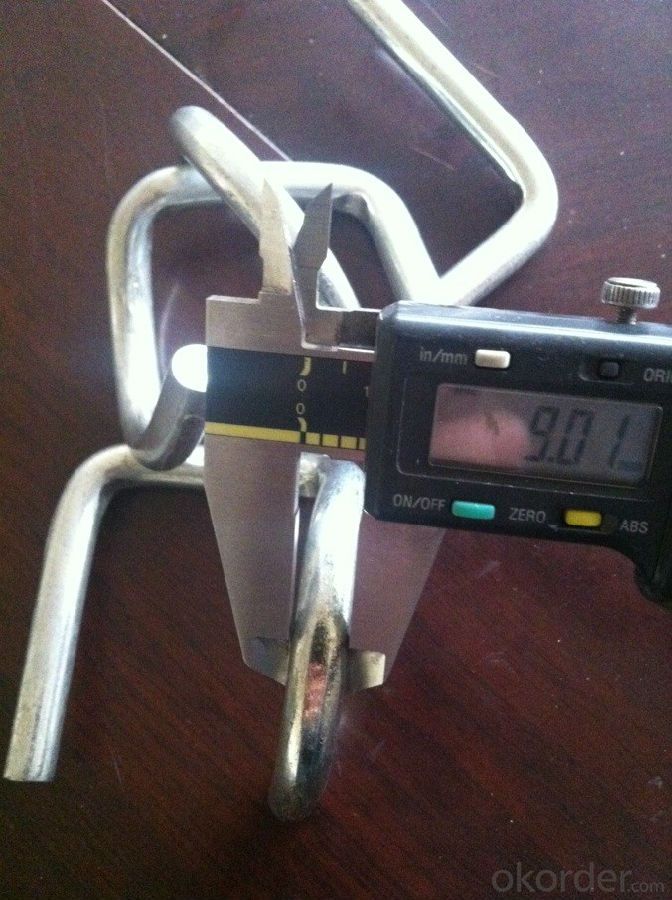

Size: 12x40mm,0.03kg;12x50mm,0.045kg

Standard: EN74

Material: Q235

Surface: self,galvanzied.

Provide OEM service

Item | Scaffolding Frame Brace Lock Pin |

Material | Q235 |

Dimensions | 12x40mm,0.03kg;12x50mm,0.045kg |

Surface | self,galvanzied |

Standard | EN74 |

Note | OEM service is available |

MOQ | 3000pieces |

Package | in steel pallet |

Payment Terms | TT,L/C, we can contact in detail |

Delivery Time | 20-30days |

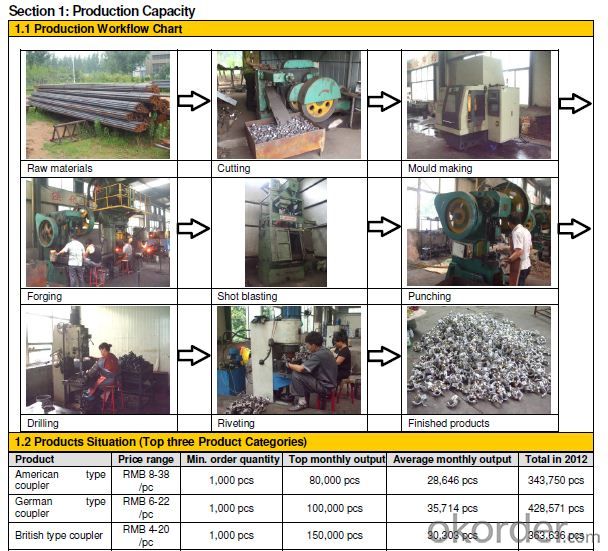

Production Equipment

We have full set of production equipment, including model machine, punching machine, rolling machine, sand blasting and etc. These production equipments will show how the products are produced and we also can produce as your requirements using these equipments.

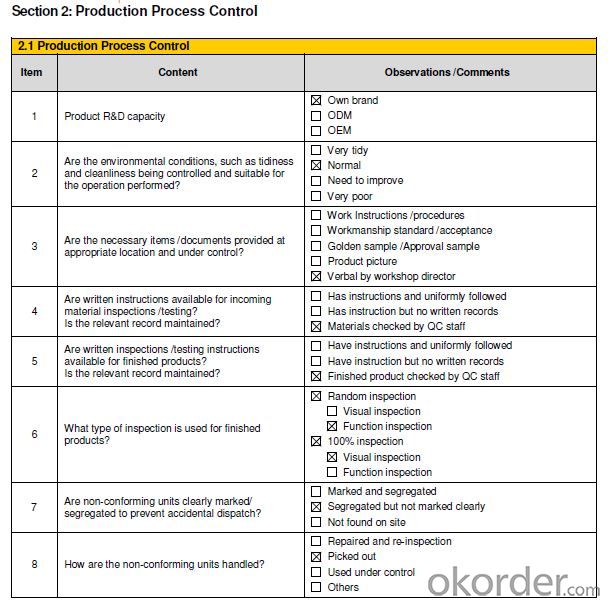

Quality Control

Recognizing that quality control is a key factor that determines success in overseas markets, our factory uses state-of-the-art facilities to ensure products meet the standards in the United States and European countries.

Packing

Knitting bag and pallet .

OEM severice avalible

1)our ability to customized production to meet customer's specifications and requirements

2)our focus on building deep long-lasting relationship with our customers

3)our commitment to meet customers needs

Quality comes first ,customers are the highest ,operate with honest

why you choose us ?

1)Highest quality -never use any equipment that is damaged or deteriorated in any way

2)Safety -inspect all equipment before using

3)Competitive price - factory suppler direct

4)We have strong engineering team that can give best solution for your project

5)Cutting -Edge product development

Consult your scaffolding supplier when in doubt-scaffolding is his business .Never take chances

Our firm belief that our customer's success are the only guarantee of our success .

- Q: What are the chances of cracking the tile? What can I do to avoid cracking the tile?This will be 3 levels of scaffolding on 6 inch wheels.

- Put the wheels (locked) on 2 x 12 planks. This will distribute the weight.

- Q: For the current stage of China's construction should not strengthen the specific meaning of scaffolding and support by way of the scaffolding and support the specific distinction and significance

- In order not to be involved in the whole system due to local errors, the scaffold must be separated from the formwork support, forming a stable system.

- Q: there is also shrubs and trees planted on the base of the wall and 14 feet from it

- A little late to be asking that question if you already have the contract, isn't it?

- Q: What's the film where gene Kelly dances on scaffolding? And at a gym?

- I think it's Living in a Big Way.... I could be wrong...

- Q: I know its between chapters one and two, duh. Haha, but yeah, I needa do this thing on Edmodo for school, but i accidentally left my book in my locker.):I tried looking at online versions, but you know it's so hard, right? Looking and seeing all these different versions and I cant find the place...I need where she entered the scaffold because I need to cite where she thinks about how she's accepted her quot;sinquot;. So yeah~ PLEASE HELP! ( gt; . lt; )

- i'm no longer completely constructive of the answer to this actual question, yet I only finished a unit in this novel and could like to help with any extra questions...be satisfied to invite -Alice

- Q: why scaffold need for inspected within the preceding 7 days and after adverse weather condition?

- It is a work safety issue. Past experience has shown that scaffolding sometimes gets modified by unqualified people (or weather) resulting in injury or death.

- Q: Are the terms quot;nuclear matrixquot; and quot;nuclear scaffoldquot; interchangeable? I know that when we talk about DNA compaction we say that MARs on the DNA attach to the nuclear scaffold. I am wondering if the scaffold is just a specific part of the matrix??

- For most purposes, they are interchangeable terms for the same things. Some people favor one term, some the other. The ones who favor matrix over scaffold or vice versa may have some argument as to why it is better or a difference but in general people use them interchangeably.

- Q: Because my friend wants it done but isn't sure :)

- probably 18. depends on your state. look it up or ask them.

- Q: Okay, quick question. I dropped into a couple of piercing studios yesterday to inquire about getting a scaffold done. Both places informed me that it's not a good idea to have it pierced with a bar straight off, as the pressure from the jewellery combined with the swelling when first pierced can seriously slow down the healing rate. Is this true? The second place said they will pierce both holes with rings, and these can be changed to a bar after around 6 to 8 weeks.Is this the best option? Thanks for any replies.

- That is true, but it's an even worse idea to have an industrial done with rings. This is because your body can move your piercings slightly, to accommodate the angle that works best for your body. In general, that's not a bad thing, but with industrials, it's a problem. You may find that an industrial healed with rings may not accommodate a bar well; the piercing may heal unaligned, and wearing a bar could be painful or impossible. Plus any shop that thinks changing from rings to a bar at 6 to 8 weeks will make any difference from getting a bar initially, you shouldn't trust to poke needles in you. Industrials take 6 months to a year or more to heal. At 8 weeks, the piercings are still very much healing. So if you have your jewelry switched at that point, you'll be irritating the piercing, setting back healing, and you'll have to deal with all of the pressure and hypertrophic scarring problems anyway. It basically comes down to this, industrials suck to heal. Bars are hard to heal. But rings will often result in bad industrial placement and alignment. Just get pierced with a bar and deal with the problems as they come. It's still very much possible to heal an industrial, it just takes time, patience, and a really good piercer (and like I said find a better shop, whoever told you it'd work to change the jewelry from rings to a bar at 8 weeks is an idiot).

- Q: Okay so i have one cartilage piercing already.plan a) i just get a scaffold piercing using already the cartilage piercing i haveplan b) i get another cartilage piercing then just wait for a while get a straight titanium barbell and stick it in threw bothI also need help convincing my mom.Help Me Out Please Thnk You

- Sorry to rain on your parade, but neither of those plans will work. Scaffold piercings need to be lined up a certain way in your ear, so you can't start with an existing piercing because you can't change your ear to fit what is already pierced. Scaffold piercings also need to heal with a bar in for them to be able to support a bar. You can't just get 2 cartilage piercings and stick a bar through. They won't line up and may not be able to support the extra weight of the bar, and migrate out. Seriously, do some research and wait until you are 16 at least.

Send your message to us

SScaffolding Frame Accessoris Lock pin

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords