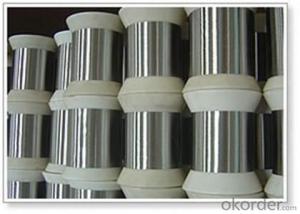

ss wire 410 for making scrubber,scoures

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel wire 201,304,316

1.Quality:ISO9001:200

2.Diameter:0.1-15mm

3.Type: hot rolled and pickled

4.Factory price

stainless steel wire 201,304,316

Steel mark includes: SUS201, SUS202,

SUS301, SUS302, SUS303, SUS304,

SUS304L, SUS316, SUS316L, SUS321,

SUS410, SUS430

| specifications and models table of steel wire | ||

| diameter mm | diameter mm | diameter mm |

| Φ0.5 | Φ1.8 | Φ5 |

| Φ0.6 | Φ2.0 | Φ5.5 |

| Φ0.8 | Φ2.2 | Φ6 |

| Φ0.9 | Φ2.5 | Φ6.3 |

| Φ1 | Φ2.8 | Φ7 |

| Φ1.1 | Φ3.0 | Φ7.5 |

| Φ1.2 | Φ3.2 | Φ8 |

| Φ1.4 | Φ3.5 | Φ8.5 |

| Φ1.5 | Φ4.0 | Φ9 |

| Φ1.6 | Φ4.5 | Φ9.5 |

Description:

1) Grade: 201,202,301,304,304L,310S,316,316L,410,420,430,etc.

2) Standard: AISI, ASTM, DIN, GB, JIS, SUS

3) Dimension:0.05mm-25mm

4) Finish: Black/Bright/Pickled/Polished

5) Length: Unlimited or as customer decided

6) Condition: Hot Rolled & Pickled, Hot Rolled Black Bar,Cold Drawn

7) Packing: Nylon bag or according to client's requirement

Terms:

Loading Port | Shanghai or Hongkong |

Delivery term | FOB,CFR, CIF etc. |

Lead time | 15-35 working days after received deposit |

Payment term | 30% by T/T as deposit., balance will be paid by T/T against copy of BL |

Quality assurance | Mill Test Certificate is supplied with shipment, third Party Inspection is acceptable |

Product Application | With bright surface, slight magnetism and no cracks on forming, is widely used in bicycle fittings, kitchen and sanitation tools, goods shelf, pet cages, gill racks, |

- Q: What are the types of cleaning equipment

- The question you ask is unscientific, and there is no way to answer it at all At least a small class

- Q: What are the benefits of sanitation

- The protection equipment and make it is not too bad

- Q: What is the issue of cleaning equipment? Is there a difference between industrial cleaning equipment and common equipment?

- The highest rated working pressure of the industrial high pressure cleaning machine is much higher than the highest rated working pressure of the commercial high pressure cleaning machine. 2: under the same technical parameters (pressure flow), industrial high pressure cleaner can effectively continuously working time is more than commercial grade high pressure cleaner can effective working hours continuously. 3: under the same technical parameters (pressure flow), industrial high pressure cleaner of the pump head and the whole machine volume is greater than that of commercial grade high pressure cleaner pump head and engine volume. 4: under the same technical parameters (pressure flow), the value of industrial high pressure cleaner and service life is far greater than the value of commercial grade high pressure cleaner and service life. The pump head material of the industrial high pressure cleaning machine must be made of alloy steel, and the pump head of the commercial class high pressure cleaning machine usually USES copper or aluminum. Generally, the price is determined by several parameters. After all, it is more complicated, considering your needs and consulting the manufacturers. The company used in the previous company is the washing equipment made by chengdu power feng, the pre-sale and after-sale service is very good, you can also consult.

- Q: Characteristics of cleaning equipment of cleaning equipment

- High pressure water jet cleaning mainly has the following characteristics: (1) selecting the appropriate pressure level, the water jet cleaning will not damage the base of the cleaning equipment. (2) is using ordinary tap water with a high speed washed clean, so it does not pollute the environment, anti-corrosion equipment, won't cause any mechanical damage, can also be removed with chemical cleaning of refractory or cannot dissolve the special scale; (3) after washing, the equipment and parts shall not be cleaned; (4) cleaning parts that are complex in shape and structure, which can be cleaned in a space narrow, complex, hostile and harmful environment; (5) it is easy to achieve mechanization, automation and digital control. (6) save energy, clean efficiency and low cost. Chengdu feng cleaning machine, with its strong technical force and reliable after-sales service protection, the pressure washer in the domestic many areas have a large promotion, cleaning machines are exported to overseas markets, done a good job in the technology field.

- Q: Where can I buy cleaning equipment

- what about cleaning, washing? Cleaning? Wash the wall? Marble? Or what, is there a direction

- Q: What cleaning equipment does the factory clean equipment need?

- Cleaning equipment as the name suggests is designed for cleaning machinery and equipment, cleaning equipment in the workplace play an effective cleaning effect, reduces the labor cost of clean cleaning equipment at the same time also improves the work efficiency and cleanness is indispensable to modern society.

- Q: The heavy oil on the machine should use what cleaning agent to clean up?

- The downstairs brother was right. I'm the one who often USES this oil cleaner, Because it's local, it's clear that it works well. I recommend you to consult..

- Q: The oil can be cleaned by the tank cleaning and the cleaning of the tank is the cleaning of the machine

- The tank cleaning industry at present, the general take artificial cleaning, mechanical equipment cleaning tank is just rise recently, really can do mechanical cleaning also does not have a few, and some manufacturers are generally abroad, prices more expensive each device also need to around 10 million, as currently on the market what the robot cleaning tank while the price is cheaper, but the technology is relatively insecure, we cleaning company is this year just at the beginning of the year on a mechanical cleaning equipment, the effect is good, the key is cheap compact result, oil recovery rate can reach 90%, in the process of cleaning is content value.

- Q: Clean the cleaning parameters of the equipment

- Judge a ultrasonic cleaning machine general technical indicators as to stay ageing degree and resonant, impedance and impedance matching are already debugged before they go out, the key lies in you to do. Of course, the sound of ultrasonic cleaning machine and generator is now being silenced. The bonding mode of the oscillator is usually made of special cement, and the bolt fastening effect is good, but it is not suitable for maintenance. Frequency selection is cleaned according to the workpiece to decide, general material or on the surface is not very high, with 28 KHZ, more strict for cleaning, or had better choose high precision parts. This is because, the lower the frequency of the bubbles, the greater the when ultrasonic frequency is greater than 800 KHZ, there is no cavitation bubbles, this to be the effect of cleaning the surface of the cavitation corrosion is the lowest. In addition, the ultrasonic cleaning is the effect of the high pressure produced by an empty bubble in the instantaneous blast.

- Q: How do you clean the inside of the electric oven? Can you use a wire ball or a detergent?

- Do not use steel wire ball, long emperor is galvanized tank, our long emperor CRDF25, with that kind of absorbing water, small pieces of clean with warm water and detergent to wash, then dry with a towel

Send your message to us

ss wire 410 for making scrubber,scoures

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords