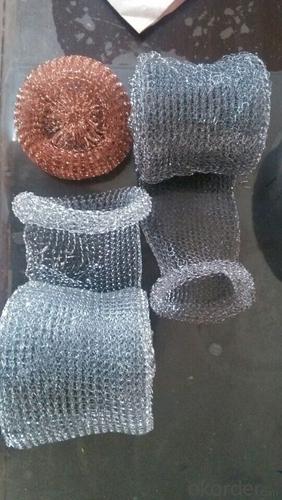

stainless steel scourer/sponge/cleaning ball

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100tons m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

stainless steel scourer, cleaning ball, sponge

blister packing 12g~100g

stainless steel scourer cleaning ball1. the material is galvanized wire.

2. It is widely in kitchen to clean and household ware's cleaning.

3. It doesn't hurt the pots & pats, of course, doesn't also hurt our hands.

4. There are 8-30g/pc and follow your requirement.

5. About the package, it can be packed in OPP bag, ploybag, blister card, hanging card and follow your requirement.

We specilize in manufaturing stainless steel scourer, galvanized scourer and copper scourer. Relying on high quality, reasonable price and best serivce, we have got the good reputation in domestic and abroad. Welcome old and new customers to negotiate the business with us , we sincerely look forward to hearing from you

Material: Stainless steel 410,430,or galvanized steel ,Brass wire diam.:0.12mm to 0.3mm

Weigh: 6g/pc-60g/pc,or according to your requests

Package:bulk packing bag packing blister packing as your requests

Advantages:Directly from factory

Strong cleaning,harmless to your hand and any pots ,pants

Effective to clean away the stubborn stains

High quality with resonable and competitive price.

Welcome to visit our compay !

- Q: What are the types of cleaning equipment

- That is too much There are all kinds of homes, there are all kinds of business, and there are all kinds of special things

- Q: What should I consider? To solve the

- Cleaning equipment at present, a lot of international medical devices by using ion exchange, reverse osmosis and ion exchange group legal and reverse osmosis and EDI combination preparation of medical apparatus and instruments clean water, the water treatment equipment manufacturers aimed at the development of medical cleaning equipment market space, are put into research and development industry. According to the process of the preparation of ultra-pure water, there must be an advantage in the development of devices.

- Q: What are the sanitation facilities?

- Sanitation equipment including road cleaning equipment, trash pickup device, the landfill treatment equipment, now the fog haze weather serious mainstream sanitation develop haze reduction equipment manufacturer. And so on.

- Q: What is the difference between industrial cleaning equipment and general cleaning equipment?

- The main difference: Service life: no less than 5, 000 hours in industry and not more than 2, 000 hours in general. Second, can carry on a continuous cleaning operation and the general cleaning machine can not do the continuous cleaning, can only be used intermittently. Third, the ability to adapt to the environment: the industry can adapt to the bad indoor environment or the outdoor working environment and the general cleaning machine is less adaptable. The industrial type is 1.5 to 2 times larger than the commercial machine, and the overall weight of the equipment is large. The general cleaning machine is beautiful in appearance, and it is very bad for the impact and collision ability.

- Q: How often do the reverse osmosis of pure water equipment wash the search?

- RO reverse osmosis membrane using time according to the general use of regional water quality or in front of the RO membrane filter replacement time, water a day in front of 5 litres of about half a year to replace the RO membrane filter, RO membrane can be used commonly 2 years no problem. The RO film is not well cleaned and should not be used.

- Q: Where can I buy cleaning equipment

- what about cleaning, washing? Cleaning? Wash the wall? Marble? Or what, is there a direction

- Q: Is it ok to clean the car with a dry ice cleaner?

- It's the best way to clean it up, it's just expensive. Because of the plane, numerical control machine, precise instrument is cleaned more frequently. There is also a lot of cleaning for cars, mainly for luxury cars.

- Q: Article 84 in GMP, the production equipment shall be cleaned according to the operating procedures specified in detail. Production equipment cleaning procedures shall stipulate detailed and complete cleaning methods, cleaning with the name of the equipment or tools, cleaning agents and preparation method, to remove the previous batch identification methods, protect already clean equipment before use from pollution methods, already clean equipment for the longest time limit, preserved...

- This time is dirty time, oneself according to the production requirements for 3 days, 3 days after completing equipment use clean, if qualified, cleaning validation then SOP can regulation equipment should be used in within 3 days from the end of the cleaning.

- Q: It is best to wash mechanical equipment using that cleaner

- See what equipment needs to be cleaned, the current cleaning agent is nutritionally ionized, non-ionized... Principle: 1. The cleaning agent shall not be related to damage, corrosion and pollution. Effectively remove dirt; You can satisfy these two principles

- Q: How do you clean the inside of the electric oven? Can you use a wire ball or a detergent?

- First wear latex gloves, detachable parts are removed inside the oven, such as baking, chassis, and then with a neutral detergent washing, paying special attention to oil dirties is very heavy, can use special cleaning fluid, such as the kitchen cleaner to do the key parts of decontamination. Then put an old newspaper in the door of an embedded oven and brush the broken pieces of the oven out of the oven with a small brush. Outside of the inside of the oven to heat pipe and heat pipe shield must use dry cloth to wipe gently, can't use a wet cloth, so as not to affect the heating pipe insulation, leakage phenomenon of short circuit. Except for the removable part of the oven, it is not possible to scrub clean and water with water or a wet cloth. If found the heating tube and fence are dirty, with dry cloth to wipe clean, also can not change with the rough surface such as steel wire ball, clean ball cleaning tools to wipe. If you have wire or hard particles falling into the heating tube, light barbecue an unpleasant feeling of anxious burnt flavour, or cause the entire circuit short circuit, can try to use clean force strong nylon cloth is wiped a few times more. After cleaning the heating tube, you can begin to clean the outer shell of the oven and the inside bladder. The cloth in the diluent of neutral detergent slightly wet, wipe with wet wipe the body shell, dip again after cleaning, diluent, and wring dry, into the oven inside pumice, final reoccupy clear water rinse wipe dry after dry, wipe it twice.

Send your message to us

stainless steel scourer/sponge/cleaning ball

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100tons m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords