mesh scourer making machine,single-needle mesh scourer machinewith Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Sets set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

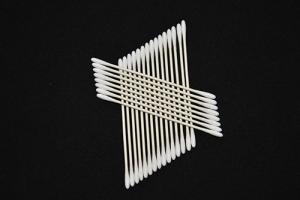

Mesh scourer making machine

High output and quality

Professional supplier

Best price and service

Full automatic

- Q: What are the types of cleaning equipment

- That is too much There are all kinds of homes, there are all kinds of business, and there are all kinds of special things

- Q: What are the benefits of sanitation

- Love, what do you say is the advantage of washing your car every day

- Q: Procter &gamble has some common cleaning equipment in the cleaning of the property

- Carpet cleaning smoke wash machine: mainly used to assist in cleaning the carpet, CDT8 triad carpet of type pumping washing machine to clean carpets, apply to the area is small or large area, is deeply clean the school and office carpet ideal equipment. The suction motor is strong and efficient, the suction system pressure loss is small. Set spraying, washing, suck, and other functions in one, dedicated to cleaning all kinds of high-grade cloth art, carpet and other fiber products, dedicated to cleaning all kinds of cloth art sofa can be configured, dedicated portable cleaning tools, make complex cleaning becomes more save worry save time and effort.

- Q: Characteristics of cleaning equipment of cleaning equipment

- High pressure cleaner using high pressure water jet cleaning technology, which is in the 1960 s the rise of a technology, widely used in the removal of incrustation scale proliferation, oil and other hydrocarbons residue coking, also can remove all kinds of coating stab stick coagulation soil lipid layer of gypsum, pigment, rubber, plastic, etc

- Q: What is suitable for factory cleaning equipment

- Automatic sweeping machine, used to clean the ground garbage, dust, debris and so on, is artificial clean more than eight times.

- Q: What is the difference between industrial cleaning equipment and general cleaning equipment?

- The main difference: Service life: no less than 5, 000 hours in industry and not more than 2, 000 hours in general. Second, can carry on a continuous cleaning operation and the general cleaning machine can not do the continuous cleaning, can only be used intermittently. Third, the ability to adapt to the environment: the industry can adapt to the bad indoor environment or the outdoor working environment and the general cleaning machine is less adaptable. The industrial type is 1.5 to 2 times larger than the commercial machine, and the overall weight of the equipment is large. The general cleaning machine is beautiful in appearance, and it is very bad for the impact and collision ability.

- Q: How often do the reverse osmosis of pure water equipment wash the search?

- Generally 3 ~ 12 months clean, if every month had to be cleaned once, this explanation should improve the pretreatment system, adjust the running parameter. If you need to clean it once or three months, you will need to improve the operating level of the equipment, and it is difficult to determine if you need to improve the pretreatment system.

- Q: The main parameters of ultrasonic cleaning equipment

- Frequency: greater than 20KHz, which can be divided into low frequency, medium frequency, high frequency 3 segments. 2. The power density, power density = transmission power (W)/launch area (cm2) usually acuity 0.3 W/cm2, the higher the power density of the ultrasonic and cavitation effect is stronger, the faster, the better cleaning effect. But for delicate, surface finish, the high power density of long time can be used to "cavorate" the surface of the object. 3. The ultrasonic frequency, ultrasonic frequency is lower, the easier the cavitation in the liquid, the strength is big, has the stronger, is suitable for the workpiece (coarse, dirty) at the beginning of washing. High frequency of ultrasonic direction, suitable for fine cleaning. 4. Clean temperature: generally speaking, ultrasonic at 30 ℃ and 40 ℃ when cavitation effect is best. The higher the temperature, the greater the effect. Normally when actual application of ultrasonic wave, using the working temperature of 50 ℃ to 70 ℃.

- Q: Article 84 in GMP, the production equipment shall be cleaned according to the operating procedures specified in detail. Production equipment cleaning procedures shall stipulate detailed and complete cleaning methods, cleaning with the name of the equipment or tools, cleaning agents and preparation method, to remove the previous batch identification methods, protect already clean equipment before use from pollution methods, already clean equipment for the longest time limit, preserved...

- It's ok for me to do it myself, and I can clean it for one week. Stay clean during the need after the sweep on the wash room, according to the requirement to avoid cross-contamination if contaminated with other material, and not be removed, the cleaning procedure if need to change the other material pollution, fashioning conservation measures

- Q: It is best to wash mechanical equipment using that cleaner

- It is recommended that the blue flying machine will be used for cleaning the surface of the equipment, cleaning the surface of the equipment and not damaging the paint on the surface of the equipment.

Send your message to us

mesh scourer making machine,single-needle mesh scourer machinewith Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Sets set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches