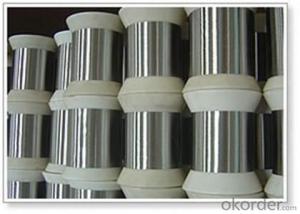

Ss wire410.0.13mm for kitchen scourers,15kg/spool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

HS stainless steel wire 0.13mm

1.Material:stainless steel 410/430

2.Different weight/packing

3.durable

4. 200Series-201,202,200Cu,201Cu.

300Series-301.302,303,303Cu,304,304Cu,304H,316,316L.

400Series-410,416,420,420F,430,430F.

5.Widely used for manufacturing bicycle fittings, kitchen and sanitation tools, goods shelf, pet cages, grill racks, decorative handles and baskets, food and medical machinery accessory, etc. And then, being used for forming and maching, our shaped wire is widely used for various profiling wire such as brassiere wire, watch bands, earphone frames, filter, etc.

Wire Diameter(mm) | Tolerance(mm) | Max. Deviation Tolerance (mm) |

0.020-0.049 | +0.002 -0.001 | 0.001 |

0.050-0.074 | ±0.002 | 0.002 |

0.075-0.089 | ±0.002 | 0.002 |

0.090-0.109 | +0.003 -0.002 | 0.002 |

0.110-0.169 | ±0.003 | 0.003 |

0.170-0.184 | ±0.004 | 0.004 |

0.185-0.199 | ±0.004 | 0.004 |

0.200-0.299 | ±0.005 | 0.005 |

0.300-0.310 | ±0.006 | 0.006 |

0.320-0.499 | ±0.006 | 0.006 |

Wire Diameter(mm) | Tolerance(mm) | Max. Deviation Tolerance (mm) |

0.020-0.049 | +0.002 -0.001 | 0.001 |

0.050-0.074 | ±0.002 | 0.002 |

0.075-0.089 | ±0.002 | 0.002 |

0.090-0.109 | +0.003 -0.002 | 0.002 |

0.110-0.169 | ±0.003 | 0.003 |

0.170-0.184 | ±0.004 | 0.004 |

0.185-0.199 | ±0.004 | 0.004 |

0.200-0.299 | ±0.005 | 0.005 |

0.300-0.310 | ±0.006 | 0.006 |

0.320-0.499 | ±0.006 | 0.006 |

- Q: The equipment of our unit needs to be cleaned regularly, oil pollution is very much, every time manual washing efficiency is too low, what method can be solved quickly?

- Normally use a sponge to absorb it, and then paste it with the dough. The equipment is special, and the larger tank is recommended to be manually and relatively clean. The small fuel tank recommended washing during operation and increasing the filter frequency. The best solution is to find the source of the oil, such as external dust pollution, internal wear and tear, and the quality of oil, which is solved by the root cause.

- Q: What are the types of cleaning equipment

- That is too much There are all kinds of homes, there are all kinds of business, and there are all kinds of special things

- Q: What is the cleaning equipment?

- The use of clean devices must be used by everyone. This calls for clean devices to be developed in a simplistic direction, lowering the barriers to entry and allowing clean devices to be used like "dumb" cameras. The development of clean equipment also requires manufacturers to make products that are easier for people to use, in order to maximize the needs of different users. To create convenience for users is to create wealth for ourselves.

- Q: What is the pool cleaning equipment

- That should see you need to manually or automatic, manual cleaning equipment include: trolley, water pump, the suction sewage pipes, telescopic rod, suction pool head, pipe bend, and so on. Fully automatic is a complete set of facilities, which is ready to go directly to the water.

- Q: What is the difference between industrial cleaning equipment and general cleaning equipment?

- The performance and usage difference of industrial high pressure cleaning machine and commercial class high voltage cleaning machine Under the same technical parameters (pressure flow), industrial high pressure cleaner can effectively continuously working time is more than commercial grade high pressure cleaner can effectively work time continuously, industrial-grade pressure washer pump head and the whole machine volume is greater than that of commercial grade high pressure cleaner pump head and the whole machine volume, the value of industrial high pressure cleaner and service life is far greater than the value of commercial grade high pressure cleaner and service life. Industrial washing machine, just as its name implies is to meet the industrial and mining enterprises such as poor environment, long running time and large amount of cleaning and higher requirements on the cleaning efficiency of unit designed for the professional cleaning machine; The design and manufacturing of the product are all about the convenience of the future and the purpose of fighting the complex environment. The industrial type cleaning machine is used to adapt to different working and mining conditions. The product is based on maintainability; The equipment is reliable, leather and durable, and its lifespan is more than three times that of other washing machines. The industrial cleaning machine is usually heavy steel structure, reliable and durable. The configuration of overpressure, overload protection, high heat value, high heat efficiency, quiet work and low noise. Low cost of heating and maintenance. Professional industrial cleaning machines are more suitable for environmental factors such as the weather, water quality, wind sand and ground, etc., and have longer life.

- Q: Is it ok to clean the car with a dry ice cleaner?

- Sure! But dry ice machine to clean is wasted, because most of the dry ice machine is cleaning the car at the bottom of the tank or car, car cleaning is commonly used water cannons and vacuuming suction machine, conditional a steam cleaner to wash the car for the internal high temperature disinfection

- Q: What cleaning equipment does the factory clean equipment need?

- A, plant, Workshop area mainly include workshop and warehouse, the characteristics of the environment is that difficult to clean and dirty, the area is large, the environment need to be efficient driving type washing machine, charge can clean the tens of thousands of square meters area, effectively improve the level of clean. Second, office space The office area usually is laid carpet according to need, so general can not use the ground machine. We need to use a vacuum cleaner for the daily cleaning of the carpet, and if we are not careful with the carpet, we need to use the suction machine. Carpet in the middle of care we need to use dry foam carpet cleaning machine, foam carpet cleaning machines and carpet washing machine and spray carpet smoking machine equipment, such as carpet of general and one month to do a thoroughly clean, can effectively remove dirt. When the carpet is cleaned in the long run, it is difficult to clean thoroughly in the middle and late stage, and then you need to use a carpet washing machine. The carpet washing machine can be used in the middle and later of the carpet to clean the carpet effectively, can make carpet the refurbishment work, the surprise that can surprise unexpectedly! Outdoor squares and open Spaces These places usually area is large, open, open, although it is difficult to clean, but not general cleaning requirements is very high, you just need to keep the floor clean. We recommend sweeping machines to remove dirt and dirt from the ground and keep it clean.

- Q: The heavy oil on the machine should use what cleaning agent to clean up?

- The downstairs brother was right. I'm the one who often USES this oil cleaner, Because it's local, it's clear that it works well. I recommend you to consult..

- Q: It is best to wash mechanical equipment using that cleaner

- In addition to cleaning and cleaning, the mechanical cleaning agent must be in four defense: anti-corrosion, rust prevention, anti-pollution and fire prevention. Because of mechanical and electrical direct relation, inevitable result can cause spark to cause needless disaster! So you need to consider buying products that are volatile, undiluted, and gasoline

- Q: How do you clean the inside of the electric oven? Can you use a wire ball or a detergent?

- First wear latex gloves, detachable parts are removed inside the oven, such as baking, chassis, and then with a neutral detergent washing, paying special attention to oil dirties is very heavy, can use special cleaning fluid, such as the kitchen cleaner to do the key parts of decontamination. Then put an old newspaper in the door of an embedded oven and brush the broken pieces of the oven out of the oven with a small brush. Outside of the inside of the oven to heat pipe and heat pipe shield must use dry cloth to wipe gently, can't use a wet cloth, so as not to affect the heating pipe insulation, leakage phenomenon of short circuit. Except for the removable part of the oven, it is not possible to scrub clean and water with water or a wet cloth. If found the heating tube and fence are dirty, with dry cloth to wipe clean, also can not change with the rough surface such as steel wire ball, clean ball cleaning tools to wipe. If you have wire or hard particles falling into the heating tube, light barbecue an unpleasant feeling of anxious burnt flavour, or cause the entire circuit short circuit, can try to use clean force strong nylon cloth is wiped a few times more. After cleaning the heating tube, you can begin to clean the outer shell of the oven and the inside bladder. The cloth in the diluent of neutral detergent slightly wet, wipe with wet wipe the body shell, dip again after cleaning, diluent, and wring dry, into the oven inside pumice, final reoccupy clear water rinse wipe dry after dry, wipe it twice.

Send your message to us

Ss wire410.0.13mm for kitchen scourers,15kg/spool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords