Cold bending square rectangular pipe for building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Cold bending square rectangular pipe for building

Square tube, square tube is a kind of call and rectangular tube, is equal and not equal to the length of steel pipe. Is the strip through the process of processing roll system. In general is the strip through the demolition of the package, flat, curly, welded to form a circular tube, and then rolled into a square tube and then cut into a square tube and then cut into the required length.

2、Main Features of Cold bending square rectangular pipe for building :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Cold bending square rectangular pipe for building Specification:

Standard | GB, DIN, ASTM |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 1.5 - 25 mm |

Section Shape | Square and rectangular |

Outer Diameter | 20*20 mm-------400*400mm 20*30mm*300*500mm |

Place of Origin | Tianjin, China (Mainland) |

Length | 3-12M |

Outer Diameter | 20*20 mm-------400*400mm 20*30mm*300*500mm |

Grade | 235B 345B |

Standard | ASME, ASTM |

1) Material:(ASTM A 106/A53 GRB.API5LGRB,GB,235B,345B

2) Specification range:OD: 20*30mm----300*500mm 20*20 mm---400*400mm ,WT: 1.5 - 25 mm ,length:3-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut ,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Cold bending square rectangular pipe for building

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

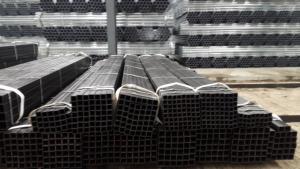

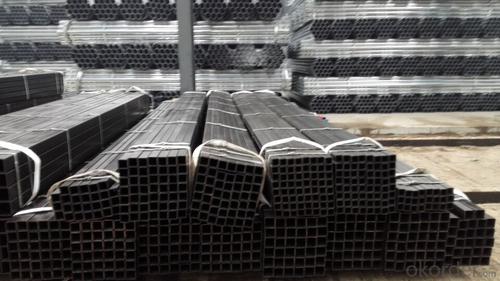

6、Cold bending square rectangular pipe for building Images:

- Q: Can steel pipes be used in earthquake-prone areas?

- Indeed, in areas prone to earthquakes, steel pipes have the potential to be employed. Steel, as a durable and sturdy material, possesses the capacity to endure the forces generated during an earthquake. The malleability and pliability of steel facilitate the absorption and dissipation of seismic wave energy, thereby decreasing the likelihood of structural failure. Furthermore, the ability to weld steel pipes enables the construction of resilient and earthquake-resistant edifices. Nevertheless, it is crucial to adhere to appropriate engineering and construction practices to guarantee the proper installation and connection of steel pipes, thereby maximizing their capacity to withstand earthquakes. Additionally, it is imperative to consider local building codes and regulations to ensure compliance and safety in earthquake-prone regions.

- Q: How do you prevent freezing in steel pipes during cold weather?

- To avoid freezing in steel pipes during cold weather, there are various steps that can be taken: 1. Insulating the pipes proves effective in safeguarding them from freezing. Utilize insulation sleeves or wraps to cover the pipes, especially in areas where they are exposed to low temperatures. Insulation aids in retaining heat and preventing the pipes from reaching freezing temperatures. 2. Identify and seal any air leaks around the pipes that allow cold air to enter. Use caulking or weatherstripping to seal these gaps and prevent the pipes from being exposed to cold air. 3. It is important to maintain a consistent temperature in the vicinity of the pipes. Ensure that the area is adequately heated and insulated. This will help keep the temperature above freezing and prevent the pipes from freezing. In extremely low temperatures, consider utilizing heat tape or pipe heating cables to provide additional warmth. 4. Allowing a small, continuous trickle of water to flow through the pipes can help prevent freezing. The flowing water generates heat and inhibits the formation of ice within the pipes. However, this method should only be used as a last resort due to potential water wastage. 5. If the steel pipes are located in an area that is not regularly used or if freezing weather is anticipated, it may be advisable to completely drain the pipes. Turn off the water supply and open all faucets to allow the water to drain out. This eliminates any standing water that could freeze and potentially cause the pipes to burst. It is crucial to note that prevention is key, as frozen steel pipes can result in expensive damages and water leaks. By implementing these measures, you can safeguard your steel pipes and ensure their functionality during cold weather.

- Q: What is the difference between carbon steel and cast iron pipes?

- The main difference between carbon steel and cast iron pipes lies in their composition and manufacturing processes. Carbon steel pipes are made from an alloy of iron and carbon, with additional elements such as manganese and silicon added for specific properties. They are typically stronger and more durable, making them suitable for high-pressure and heavy-duty applications. On the other hand, cast iron pipes are made by melting iron and pouring it into molds, resulting in a more brittle and less flexible material. Cast iron pipes are commonly used for drainage and sewage systems due to their corrosion resistance and sound insulation properties.

- Q: How are steel pipes used in oil and gas industry?

- Steel pipes are extensively used in the oil and gas industry for various purposes such as drilling, production, transportation, and refining. They are primarily used for the extraction of oil and gas from the ground, as well as for the transportation of these resources over long distances. Steel pipes are also utilized in the construction of storage tanks, refineries, and offshore drilling platforms. Their strength, durability, and resistance to corrosion make them ideal for withstanding the harsh conditions encountered in the oil and gas industry.

- Q: How are steel pipes repaired in case of damage or leaks?

- Various methods can be used to repair steel pipes in the event of damage or leaks. Welding is a common approach where a filler material is melted along with the damaged or leaking area, creating a strong bond that seals the leak. This method is effective for small to moderate-sized leaks and finds wide application in industries like oil and gas, plumbing, and construction. Another method involves the use of mechanical couplings. These couplings are designed to connect two sections of pipe securely, ensuring a tight connection. They can be utilized to repair damaged or leaking sections of a steel pipe by removing the damaged area and replacing it with a new section that is linked using the mechanical coupling. This method is particularly useful for larger leaks or damaged sections that cannot be repaired through welding. In certain cases, temporary fixes can be applied using pipe clamps or epoxy compounds. Pipe clamps are employed to seal the damaged area tightly, preventing further leakage. On the other hand, epoxy compounds are directly applied to the damaged or leaking section, creating a temporary seal that stops the leak until a more permanent repair can be carried out. It is essential to consider the severity and location of the damage or leak, as well as the specific requirements of the application, when deciding on the method of repair. In some instances, it may be necessary to replace the entire section of the steel pipe if the damage is extensive or if multiple leaks are present. It is advisable to consult a professional or a specialized pipe repair service to determine the most suitable repair method for a particular situation.

- Q: How are steel pipes transported?

- Steel pipes are typically transported using various methods, including trucks, trains, and ships. They are often loaded onto flatbed trucks or railcars for land transportation, while larger quantities are transported by bulk carriers or container ships for overseas shipping. The pipes are secured with straps or chains to ensure safe and stable transport, and they may also be packed in bundles or placed in specially designed containers to protect them from damage during transit.

- Q: Are steel pipes suitable for high-temperature applications?

- Yes, steel pipes are suitable for high-temperature applications. Steel has excellent heat resistance properties and can withstand high temperatures without deformation or structural failure. Additionally, steel pipes can be specifically designed and coated to enhance their heat resistance, making them ideal for various industrial processes and applications involving high temperatures.

- Q: What are the different testing methods used for steel pipes?

- There are various testing methods used for steel pipes, including non-destructive testing methods such as ultrasonic testing, magnetic particle testing, radiographic testing, and liquid penetrant testing. These methods help detect any defects or flaws in the pipes, ensuring their quality and integrity. Additionally, destructive testing methods such as tensile testing, impact testing, and hardness testing are also used to evaluate the mechanical properties of the steel pipes.

- Q: Can steel pipes be used for fencing?

- Yes, steel pipes can be used for fencing. They are strong, durable, and provide excellent security. Steel pipes are commonly used in industrial and commercial settings, as well as for agricultural purposes. They can be easily welded and can withstand harsh weather conditions, making them an ideal material for fencing.

- Q: What are the common grades of steel used in pipes?

- The common grades of steel used in pipes include ASTM A53, ASTM A106, and API 5L.

Send your message to us

Cold bending square rectangular pipe for building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords