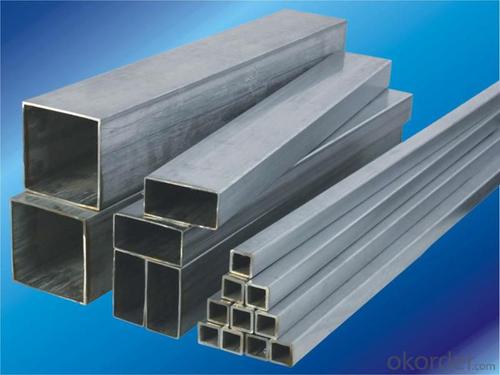

Square Steel Pipe from Okorder in China with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Square Steel Pipe Description:

The square Steel pipes are used in structural projects, shelves, racks, trailers and in ornamental purpose. The framework made by square steel tubes, is used for providing support to the roof. This framework is also used as roof top ventilation baffles. With compare to round steel pipes, square steel pipes are little more efficient. The reason is that the square column is more efficient than the solid circular column.

2. Main Features of the Square Steel Pipe:

·Prompt delivery

·Time-saving

·High quality

·Competitive price

3. Square Steel Pipe Images:

4、Square Steel Pipe Specification:

| Standard | JIS,GB,DIN,ASTM JIS G3466, GB/T 3094-2000, DIN EN 10216-1-2004, ASTM A513-2007 |

| Grade | Cr-Mo alloy, 16Mn, A53-A369, Q195-Q345 30CrMo, 16Mn, A106(B,C), Q235, Q345, Q195, Q215 |

| Thickness | 0.5 - 30 mm |

| Outer Diameter | 10x10---600x600 |

| Technique | Cold Drawn |

| Application | Structure Pipe |

| Certification | ISO9001 |

| Surface Treatment | Galvanized |

Cold rolled square pipe:

1) Size: different sizes according to customers' requirement

2) Grade: many different kinds of materials.

3) Standard: GB50205-2001, JIS, ASTM and EN

4) Detailed requirement please feel free to contact

5)Specification:GB6728,DIN,JIS,ASTM-A500

6).Grade:Q195,Q235,Q345,ST37-2,ST52-3,SS400,SS355

- Q: How are steel pipes used in the manufacturing of power plants?

- Steel pipes are commonly used in the manufacturing of power plants for various purposes such as transporting fluids, gases, and steam. They are utilized for the construction of pipelines that carry water, fuel, and coolant to different parts of the power plant. Additionally, steel pipes are employed in the creation of boiler tubes and heat exchangers, which play a crucial role in the generation of steam and transfer of heat in power plants.

- Q: Can steel pipes be used for conveying sewage and wastewater?

- Indeed, sewage and wastewater can be conveyed using steel pipes. The use of steel pipes is widespread in sewage and wastewater systems owing to their robustness and resilience. They possess corrosion resistance and can endure immense pressure and flow rates. Moreover, steel pipes have the capability to manage the rigorous chemicals and pollutants found in sewage and wastewater without impairing or compromising the fluid quality. Nonetheless, it is crucial to guarantee proper coating or lining of the steel pipes to avert any potential problems concerning corrosion or contamination. Regular maintenance and inspections are equally important to detect and rectify any potential concerns that may arise within the system.

- Q: Can steel pipes be used for underwater applications?

- Yes, steel pipes can be used for underwater applications as they are known for their high strength, durability, and corrosion resistance, making them suitable for various underwater environments and industries such as offshore oil and gas, marine construction, and underwater pipelines.

- Q: Can steel pipes be used for natural gas processing plants?

- Yes, steel pipes can be used for natural gas processing plants. Steel pipes are commonly used in the oil and gas industry due to their high strength, durability, and resistance to corrosion. They can safely transport natural gas and are capable of withstanding the high pressure and temperature conditions typically found in processing plants.

- Q: How do you calculate the pipe flow rate for steel pipes?

- To calculate the pipe flow rate for steel pipes, you can use the Hazen-Williams equation or the Darcy-Weisbach equation. These equations take into consideration factors such as the pipe diameter, length, roughness, and the pressure difference between the two ends of the pipe. By plugging in these values into the respective equation, you can determine the flow rate of the fluid passing through the steel pipe.

- Q: Theoretical weight of 25*25*1.5 square steel tubes

- The theoretical weight of 25*25*1.5 square steel tubes is 1.075kg/m.

- Q: How do steel pipes resist corrosion?

- Steel pipes resist corrosion through a process called passivation, wherein a protective layer of oxide forms on the surface of the steel, preventing further oxidation and corrosion. Additionally, the pipes can be coated with anti-corrosive materials or undergo treatments such as galvanization or lining to enhance their resistance against corrosion.

- Q: Are steel pipes suitable for desalination plants?

- Desalination plants can benefit greatly from the use of steel pipes. These pipes possess a variety of advantages that make them an ideal option for such facilities. Firstly, their resistance to corrosion is of utmost importance in desalination plants, where saltwater can be highly corrosive. The fact that steel pipes can withstand such corrosive conditions ensures the durability and longevity of the infrastructure, ultimately reducing maintenance and replacement expenses. Secondly, steel pipes exhibit remarkable strength, enabling them to withstand high-pressure situations commonly encountered in desalination plants. The ability of steel pipes to handle intense water flow without deformation or leakage guarantees the efficient and dependable operation of the desalination process. Moreover, steel pipes boast excellent heat resistance properties, rendering them suitable for desalination plants that engage in heat-intensive procedures like distillation or reverse osmosis. These pipes can endure high temperatures without suffering any structural damage, ensuring the secure and efficient transfer of heated water or steam. Furthermore, steel pipes are readily available and come in a wide range of sizes and specifications, allowing for flexibility in the design and construction of desalination plants. This availability and versatility make steel pipes a cost-effective choice for desalination projects. Overall, due to their resistance to corrosion, high strength, heat resistance, availability, and cost-effectiveness, steel pipes are highly suitable for desalination plants and are extensively used in the industry.

- Q: What is a flange and how is it used in steel pipes?

- A flange is a mechanical device that is used to connect two sections of steel pipes together. It consists of a flat or raised ring that is attached to the end of each pipe section. The flange provides a surface for the pipes to be bolted or welded together, creating a secure and leak-proof joint. It also allows for easy disassembly and reassembly of the pipes when necessary. Flanges are commonly used in various industries, such as oil and gas, water treatment, and manufacturing, where the connection between steel pipes needs to be strong and reliable.

- Q: What is the role of steel pipes in the transportation of chemicals?

- Steel pipes play a crucial role in the transportation of chemicals due to their high strength and durability. They are used to safely transport a wide range of chemicals, including corrosive and hazardous substances, without the risk of leakage or contamination. The corrosion-resistant properties of steel pipes ensure the integrity of the chemicals being transported, preventing any potential damage to the environment or human health. Additionally, steel pipes can withstand high pressure and extreme temperatures, making them ideal for the efficient and reliable transportation of chemicals over long distances.

Send your message to us

Square Steel Pipe from Okorder in China with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords