Suare High Quality Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25-35 watt

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 0.45 - 2.5 mm | Section Shape: | Square | Place of Origin: | Hebei China (Mainland) |

| Secondary Or Not: | Non-secondary | Application: | furniture pipe. fence tube,structure pipe etc.,handle railings.fence tube,shelves, furniture, threading tube | Technique: | Cold Rolled |

| Certification: | 50x50mm square pipe | Surface Treatment: | pre-galvanzied,black,pre-galvanized,black annealed | Alloy Or Not: | Non-alloy |

| Material: | Q195,Q215,Q235 | Technology: | Colled rolled | Wall thickness: | 0.45mm-2.5mm |

| Length: | 4.5m~7m | Lenght tolerance: | +/-20mm | OD tolerance: | +/-0.5mm |

| Thickness tolerance: | +/-0.03mm | Grade: | Q235,Q195,Q215,Q195-Q345 | Standard: | GB/T3901,GB,GB/T 3091-2008 |

Packaging & Delivery

| Packaging Detail: | in bulk, in small bundle or as customer's request |

| Delivery Detail: | about 10 days after receiving customer's deposit |

Specifications

square steel pipe :

Material: Q195,Q215,Q235

Surface: pre-galvanized,black

Wall thickness: 0.45mm-2.5

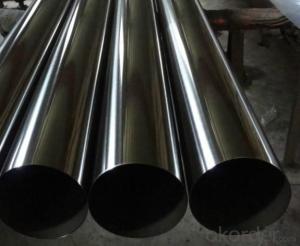

Square Pipe Image

FAQ of Square Pipe

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: How do steel pipes compare to ductile iron pipes?

- Steel pipes and ductile iron pipes are utilized in various applications, but they possess distinct differences in terms of their properties and advantages. 1. Strength and Durability: Steel pipes exhibit greater strength and durability compared to ductile iron pipes. Steel possesses a higher tensile strength, making it less susceptible to cracking or breaking under pressure or external forces. Conversely, ductile iron possesses a lower tensile strength but boasts better impact resistance than steel. 2. Corrosion Resistance: Steel pipes are susceptible to corrosion, especially when exposed to moisture or chemicals. Nevertheless, protective measures such as applying coatings or employing corrosion-resistant alloys can safeguard against this. Ductile iron pipes, while inherently more corrosion-resistant than regular cast iron, may still necessitate external protection to prevent rusting and degradation. 3. Flexibility: Ductile iron pipes offer greater flexibility than steel pipes. They can endure certain degrees of bending and deflection without fracturing, making them suitable for applications where ground movement or shifting may occur. Conversely, steel pipes are less flexible and more rigid, rendering them better suited for straight runs or applications with minimal movement. 4. Cost: Generally, ductile iron pipes are more cost-effective than steel pipes. The manufacturing process for ductile iron is easier and cheaper, resulting in lower production costs. However, steel pipes may possess a longer lifespan, requiring fewer replacements over time, thereby offsetting the initial cost difference. 5. Installation: Steel pipes are lighter and easier to handle during installation compared to ductile iron pipes, which can be heavy and bulky. The lighter weight of steel pipes can reduce labor and transportation costs. Moreover, steel pipes can be welded, allowing for more flexible installation options, while ductile iron pipes are typically joined using mechanical couplings or flanged connections. In conclusion, steel pipes offer superior strength and durability, while ductile iron pipes provide better flexibility and cost-effectiveness. The selection between the two depends on the specific requirements of the application, including factors such as corrosion resistance, expected loads, installation conditions, and budget constraints.

- Q: What is the role of steel pipes in the construction of stadiums?

- Steel pipes play a crucial role in the construction of stadiums as they are used for various purposes including structural support, drainage systems, and the installation of utilities such as water, gas, and electrical lines. These pipes provide the necessary strength and durability to support the weight of the stadium's roof, seating areas, and other infrastructure. Additionally, steel pipes enable efficient transportation of liquids and gases, ensuring proper functioning of the stadium's facilities.

- Q: What are the common methods of joining steel pipes?

- The common methods of joining steel pipes include welding, threading, and using mechanical couplings. Welding involves fusing the pipes together using heat, while threading involves screwing the pipes together using threads on the ends. Mechanical couplings are devices that connect the pipes together using compression or other means.

- Q: How are steel pipes used in fire protection systems?

- Steel pipes are an integral part of fire protection systems, primarily used for the distribution of water or other fire suppressants in buildings. These pipes are known for their strength, durability, and resistance to high temperatures, making them ideal for withstanding the intense conditions of a fire. In fire protection systems, steel pipes are commonly used to create a network of pipes that deliver water to sprinkler heads or fire hydrants throughout a building. This network ensures that water is readily available to suppress or extinguish a fire in case of an emergency. One of the key advantages of steel pipes in fire protection systems is their ability to withstand the high pressure and flow rates required for effective fire suppression. Steel pipes can handle the forceful water flow needed to quickly and efficiently distribute water to the affected areas, helping to control and extinguish the fire as soon as possible. Additionally, steel pipes are resistant to corrosion, which is essential for maintaining the integrity of the fire protection system over time. Corrosion can weaken pipes, leading to leaks or even complete failure, which can be catastrophic in a fire situation. Steel pipes, however, have a longer lifespan and require less maintenance compared to other pipe materials, ensuring the system remains reliable and functional for years to come. Furthermore, steel pipes are often used in fire protection systems due to their fire resistance properties. Steel is inherently fire-resistant, meaning it can withstand high temperatures without deforming or losing its structural integrity. This is crucial in fire protection systems as it allows the pipes to remain intact and continue delivering water even in the midst of a fire, ensuring the safety of occupants and minimizing damage to the building. In summary, steel pipes play a vital role in fire protection systems by ensuring a reliable and efficient distribution of water or fire suppressants. Their strength, durability, resistance to high temperatures, and corrosion resistance make them an ideal choice for effectively combating fires and safeguarding lives and property.

- Q: What is the difference between steel pipe and copper pipe?

- The main difference between steel pipe and copper pipe lies in their material composition. Steel pipe is made of steel, while copper pipe is made of copper. Steel pipe is stronger and more durable, making it suitable for high-pressure and heavy-duty applications. On the other hand, copper pipe is more malleable and corrosion-resistant, making it ideal for plumbing and water supply systems. Additionally, copper pipe is more expensive than steel pipe but offers better heat conductivity, making it suitable for heating and cooling applications.

- Q: How do you prevent steel pipes from freezing in cold climates?

- To prevent steel pipes from freezing in cold climates, it is important to insulate the pipes properly. This can be done by wrapping them with insulation sleeves or foam, which helps to retain heat and prevent rapid temperature changes. Additionally, ensuring that there is proper ventilation in the area where the pipes are located can help to maintain a higher temperature and prevent freezing.

- Q: Where is a steel pipe casing usually used?

- Classification of casing: rigid casing, flexible waterproof sleeve, steel pipe sleeve and iron sheet bushing, etc..

- Q: What are the common applications of seamless steel pipes?

- Seamless steel pipes have numerous common applications in various industries due to their unique properties. Here are some of the most common applications of seamless steel pipes: 1. Oil and gas industry: Seamless steel pipes are widely used in the oil and gas industry for the transportation of oil, gas, and other fluids. They are preferred due to their high strength, durability, and resistance to corrosion, making them suitable for harsh environments. 2. Construction and infrastructure: Seamless steel pipes are extensively used in construction projects, including the construction of buildings, bridges, and tunnels. They are ideal for structural applications due to their ability to withstand heavy loads and provide excellent strength and stability. 3. Automotive industry: Seamless steel pipes are a crucial component in the manufacturing of automotive parts, such as exhaust systems, engine components, and hydraulic systems. They offer high strength, reliability, and resistance to heat, making them suitable for demanding automotive applications. 4. Mechanical and engineering applications: Seamless steel pipes find usage in various mechanical and engineering applications, including machinery, equipment, and manufacturing processes. They are commonly used for carrying fluids, gases, and steam, as well as for the transmission of power in machinery. 5. Power generation: Seamless steel pipes are extensively used in power plants for the transportation of steam and hot water. They are capable of withstanding high pressure and temperature, making them ideal for power generation applications. 6. Petrochemical industry: Seamless steel pipes are crucial in the petrochemical industry for the transportation of various chemicals, gases, and liquids. They have excellent resistance to corrosion, which is essential when dealing with hazardous and corrosive substances. 7. Mining industry: Seamless steel pipes are used in the mining industry for various applications, including the transportation of slurry, water, and other mining-related fluids. They offer durability, reliability, and resistance to abrasion, making them suitable for the challenging mining environment. 8. Aerospace industry: Seamless steel pipes find applications in the aerospace industry for manufacturing aircraft components, such as hydraulic systems, fuel lines, and structural parts. They provide high strength-to-weight ratio and resistance to extreme temperatures and pressure. Overall, the common applications of seamless steel pipes span a wide range of industries, thanks to their exceptional properties, including strength, durability, resistance to corrosion and high temperatures, making them an essential component in various industrial processes and infrastructure development.

- Q: How are steel pipes protected against soil movement or settlement?

- Steel pipes can be protected against soil movement or settlement through various methods. One common method is to use protective coatings on the pipes. These coatings act as a barrier between the steel and the soil, preventing direct contact and reducing the risk of corrosion. Some commonly used coatings include epoxy, polyethylene, and zinc. Another method is to use cathodic protection. This involves the installation of sacrificial anodes along the pipeline. These anodes corrode instead of the steel pipes, protecting them from damage caused by soil movement or settlement. Furthermore, proper design and installation techniques can also help protect steel pipes against soil movement or settlement. For instance, engineers may consider factors such as soil composition, slope stability, and potential for ground movement when designing the pipeline route. Additionally, proper trenching and bedding techniques can help ensure that the pipe is adequately supported and protected against settlement. Regular inspection and maintenance are also crucial for protecting steel pipes against soil movement or settlement. Monitoring the condition of the pipeline, including the protective coatings and cathodic protection systems, can help identify any potential issues and allow for timely repairs or replacements. Overall, a combination of protective coatings, cathodic protection, proper design and installation techniques, and regular maintenance can effectively protect steel pipes against soil movement or settlement.

- Q: What are the different types of steel pipe coatings for corrosive environments?

- There are several types of steel pipe coatings that are commonly used for corrosive environments. These include fusion bonded epoxy (FBE) coating, three-layer polyethylene (3LPE) coating, three-layer polypropylene (3LPP) coating, and coal tar enamel (CTE) coating. FBE coating provides excellent corrosion resistance and is commonly used for underground pipelines. 3LPE and 3LPP coatings combine a layer of epoxy, an adhesive layer, and a polyethylene or polypropylene outer layer, offering superior protection against corrosion and mechanical damage. CTE coating, although less common nowadays, is still used for certain applications due to its resistance to water and chemical corrosion.

Send your message to us

Suare High Quality Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25-35 watt

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords