Square Steel Billets Hot Sale Deformed Billet Q275/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of steel billet:

We procure world class quality steel billets which meets the specific requirements of the clients

The Billets produced by the company can be broadly divided into three main types i.e.

1.M.S. Billets

2.CRS Billets

3.Special Alloy Billets

Festures of steel billet:

Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products. Billets are used fro rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Specifications of steel billet:

Type | Steel billet / Square steel/ Steel square bar |

Standard grade | 3SP/PS, 5SP/PS, Q195, Q235, Q255, Q275, 20MnSi etc. |

MOQ | 1000 MT |

Technique | Hot rolled |

Size | 50*50mm ~ 160*160mm |

Length | 3~12m |

Packing | Loose packing, in bundle |

Payment terms | T/T, L/C at sight, Usance L/C |

Trade terms | EXW, FOB, CFR, CIF |

Trans terms | FIO, FILO, FLT |

Inspection | Third party inspection accepted |

Delivery time | 15-30 days, according to the quantity |

Applications | carbon structural steel, wire rod, rod, deformed bars, profile steel, machine parts, and steel moulds etc . |

Note | Customized service is available (for sizes,length and chemical components etc.). |

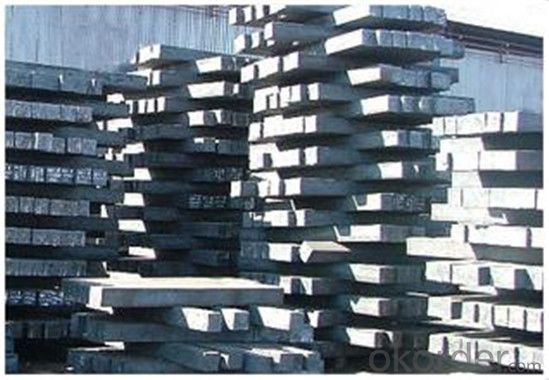

Images of steel billet:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the main factors affecting the electrical conductivity of steel wire rod?

- The main factors affecting the electrical conductivity of steel wire rod include the composition and purity of the steel, the presence of impurities or alloying elements, the crystal structure and grain size of the steel, and the temperature at which the conductivity is measured.

- Q: What is the size range of steel wire rod?

- The size of steel wire rod may differ depending on the specific application and industry requirements. Typically, steel wire rod comes in diameters ranging from 5.5mm to 20mm. Nonetheless, there may be deviations beyond this range to meet specific customer demands. The selection of the size range is influenced by factors like intended usage, strength prerequisites, and manufacturing capacities. It is crucial to seek advice from steel wire rod manufacturers or suppliers to ascertain the suitable size range for a given application.

- Q: How is steel wire rod used in the production of wire forms?

- Steel wire rod is used in the production of wire forms as it serves as the raw material. The wire rod is first drawn through a series of dies to reduce its diameter and increase its length. This process of drawing or cold working the wire rod helps in enhancing its strength and flexibility. The drawn wire is then further processed and shaped into various wire forms such as springs, clips, hooks, and fasteners, among others. The properties of steel wire rod, such as its high tensile strength and durability, make it an ideal material for creating strong and reliable wire forms for various industries and applications.

- Q: How is steel wire rod tested for yield strength?

- Steel wire rod is tested for yield strength through a standardized procedure called tensile testing. In this process, a sample of the wire rod is subjected to gradually increasing tension until it reaches its breaking point. The test measures the maximum amount of stress that the wire rod can withstand before it starts to deform permanently, indicating its yield strength.

- Q: How is steel wire rod classified based on its diameter?

- Steel wire rod is categorized into different groups according to its diameter. The categorization is typically carried out using either a wire gauge system or by directly stating the diameter in millimeters. The wire gauge system assigns a numerical value to various wire diameters, with higher numbers indicating thinner wires. In the United States, for instance, the American Wire Gauge (AWG) system is commonly employed. In this system, the thickest wire is given the gauge number 0000 (four zeros), while the thinnest wire is assigned a gauge number of 40. Each gauge number corresponds to a specific range of diameters. On the other hand, steel wire rod can also be classified according to its diameter in millimeters. With this approach, the exact diameter of the wire rod is directly specified, allowing for a more precise classification. For instance, a wire rod with a diameter of 5.5 mm would be classified accordingly. Both classification methods offer a standardized means of categorizing steel wire rod based on its diameter. This information is crucial for various industries, including construction, automotive, and manufacturing, as it enables them to select the appropriate wire rod for their particular applications.

- Q: What are the main factors influencing the price of steel wire rod?

- The main factors influencing the price of steel wire rod are the cost of raw materials, such as iron ore and scrap metal, fluctuations in demand and supply, global economic conditions, trade policies and tariffs, production and transportation costs, and market competition. Additionally, factors like currency exchange rates and energy prices can also impact the price of steel wire rod.

- Q: How is the steel wire rod market segmented by application?

- The steel wire rod market is segmented by application into construction, automotive, industrial machinery, and others.

- Q: How are steel wire rods used in the manufacturing of bicycle spokes for strength and flexibility?

- Steel wire rods are an essential component in the manufacturing process of bicycle spokes, as they provide the necessary strength and flexibility required for optimal performance. The use of steel wire rods ensures that the spokes can withstand the various forces and stresses experienced during cycling, such as the weight of the rider and impacts from uneven surfaces. The strength of steel wire rods is crucial in bicycle spokes as they need to bear the weight of the rider and transfer the force from pedaling to the wheels. Steel is known for its high tensile strength, meaning it can resist large amounts of pulling or stretching forces without breaking. This property makes it ideal for bicycle spokes, which need to support the weight of the rider and maintain stability. Furthermore, steel wire rods offer excellent flexibility, allowing the spokes to absorb and distribute external forces evenly. This flexibility helps to absorb shocks and vibrations, reducing the impact on the bicycle's overall structure and enhancing the comfort of the rider. Manufacturers typically shape the steel wire rods into a specific profile to optimize strength and flexibility. The rods are often cold-drawn, a process that increases their tensile strength while maintaining their flexibility. Cold-drawn steel wire rods are strong enough to withstand the forces applied during cycling, yet they retain enough flexibility to allow the spokes to move and adjust to various road conditions. In summary, steel wire rods play a vital role in the manufacturing of bicycle spokes for strength and flexibility. Their high tensile strength ensures the spokes can bear the weight of the rider and transfer forces effectively, while their flexibility helps absorb shocks and vibrations. Overall, steel wire rods provide the necessary durability and performance required for spokes in bicycle manufacturing.

- Q: What are the different types of steel wire rod finishes for improved adhesion in rubber products?

- There are several types of steel wire rod finishes that can enhance adhesion in rubber products. Some common finishes include copper, zinc, phosphate, and brass coatings. These finishes help to create a stronger bond between the steel wire rod and the rubber, improving adhesion and overall product performance.

- Q: How is steel wire rod used in the production of wire for suspension bridge cables?

- Steel wire rod is a crucial component used in the production of wire for suspension bridge cables. The wire rod is made from high-quality steel and is typically produced through a process called hot rolling. To create wire for suspension bridge cables, the steel wire rod undergoes several stages of processing. Firstly, the wire rod is heated and then passed through a series of rollers, which gradually reduce its size and shape it into a long, continuous wire. This process is known as wire drawing. The resulting wire is then further processed to enhance its strength and durability. It undergoes a heat treatment process, such as annealing, to improve its mechanical properties. This treatment helps increase the wire's tensile strength, ensuring it can withstand the immense loads and stresses experienced by suspension bridge cables. Once the wire has been appropriately treated, it is then carefully woven and braided to create the final suspension bridge cable. Multiple wires are twisted together to form strands, and several strands are then twisted together to create a larger cable. This intricate weaving process ensures that the cable is strong, flexible, and resistant to corrosion. The use of steel wire rod in the production of suspension bridge cables is crucial due to its exceptional strength-to-weight ratio. Steel is renowned for its high tensile strength, making it an ideal material for supporting heavy loads over long spans. Additionally, steel wire rod offers excellent resistance to corrosion, ensuring the longevity and structural integrity of suspension bridge cables. Overall, steel wire rod plays a vital role in the production of wire for suspension bridge cables, providing the necessary strength, durability, and flexibility required for these critical infrastructure components. Its versatility and reliability make it a preferred material choice in the construction of suspension bridge cables, ensuring the safety and functionality of these impressive engineering marvels.

Send your message to us

Square Steel Billets Hot Sale Deformed Billet Q275/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords