Square Steel Billets Hot Sale 3SP/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of steel billet:

Our company is recognized by ISO9001:2008

1. hot rolled wire rod

2. material: Q195-235

Festures of steel billet:

1. Drawn wire specialist, your wire rod solution

2. ISO9001 Certified Mill &SGS

3. Feature: machinability, high hardness, toughness, corrosion resistant

Specifications of steel billet:

Size | 60*60/90*90/100*100/120*120/150*150 |

Length | 6000mm-12000mm |

Standard | GB |

Applicaton | To produce bars or other applications |

Grade | Q195/Q235/Q275/3SP/5SP/20MnSi |

Packing terms | TT/LC |

Package | Mill's standard packing or as client's requirment |

Delivery time | Within 10-30 days after receiving the deposit or LC |

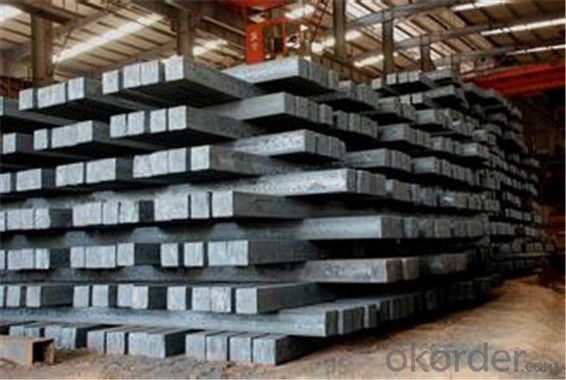

Images of steel billet:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the different types of wire mesh made from steel wire rod?

- Steel wire rod can be used to create various types of wire mesh, each with its own distinct qualities and uses. Some commonly encountered options include: 1. Welded Wire Mesh: This variant involves welding steel wire rods together at the points where they intersect, resulting in a grid-like pattern. It is frequently employed for applications such as fencing, security enclosures, and reinforcing concrete structures. 2. Woven Wire Mesh: Interlocking steel wire rods are woven together to produce this type of wire mesh. It is available in different weave styles, including plain, twill, and Dutch weaves. Woven wire mesh finds widespread usage in filtration, screening, and separation activities. 3. Expanded Metal Mesh: The steel wire rods are cut and stretched to create diamond-shaped openings in this variety of wire mesh. It possesses a lightweight yet sturdy construction, making it highly versatile for applications like walkways, security grilles, and decorative panels. 4. Perforated Metal Mesh: By puncturing holes into the steel wire rods, a pattern of openings is formed. Perforated metal mesh is commonly employed in architectural projects like facades and sunscreens, as well as for filtration, ventilation, and acoustic control purposes. 5. Knitted Wire Mesh: This type of wire mesh is formed by knitting the steel wire rods together, resulting in a structure that is both flexible and resilient. Knitted wire mesh is widely used for gaskets, seals, and filtration applications, as it offers excellent gas and liquid filtration capabilities. These examples represent only a small selection of the diverse range of wire mesh options that can be produced using steel wire rods. Each type possesses unique characteristics and serves a wide array of industrial and commercial needs.

- Q: What are the different types of steel wire rod surface treatment chemicals?

- There are several different types of steel wire rod surface treatment chemicals that are commonly used in various industries. These chemicals are designed to enhance the properties of the steel wire rod and provide protection against corrosion. Some of the most common types of surface treatment chemicals include: 1. Phosphating chemicals: Phosphating is a common surface treatment process that involves the application of a phosphate coating to the steel wire rod. This coating helps improve the adhesion of paints and other coatings, provides corrosion resistance, and enhances the overall appearance of the wire rod. 2. Pickling chemicals: Pickling is a process that involves the removal of scale and oxides from the surface of the steel wire rod. Pickling chemicals, such as hydrochloric acid or sulfuric acid, are used to dissolve these impurities and leave a clean and smooth surface. 3. Passivation chemicals: Passivation is a chemical process used to remove free iron or iron oxide from the surface of the steel wire rod. This helps to enhance the corrosion resistance of the wire rod by creating a protective oxide layer. 4. Chromate conversion coatings: Chromate conversion coatings are often used as a post-treatment for phosphating or pickling processes. These coatings provide additional corrosion resistance and improve the adhesion of paints or other coatings. 5. Anti-corrosion oils: Anti-corrosion oils are applied to the surface of the steel wire rod to provide temporary protection against corrosion during storage or transportation. These oils form a thin film that helps to prevent moisture and other corrosive substances from reaching the surface of the wire rod. It is important to note that the choice of surface treatment chemical depends on the specific requirements of the steel wire rod and the intended application. Different industries may have their own unique set of requirements and may use different types of surface treatment chemicals accordingly.

- Q: How is steel wire rod straightened after the rolling process?

- Steel wire rod is straightened after the rolling process through a mechanical process known as straightening. The rod passes through a series of rotating rollers that apply pressure and tension to remove any deformities and bends, ultimately resulting in a straightened wire rod.

- Q: What are the common industry qualifications for steel wire rod manufacturers?

- The common industry qualifications for steel wire rod manufacturers usually include certifications such as ISO 9001:2015 for quality management systems, ISO 14001:2015 for environmental management systems, and OHSAS 18001:2007 for occupational health and safety management systems. Additionally, manufacturers may need to comply with various international and national standards specific to the steel industry, such as ASTM A510, ASTM A510M, or EN 10016-2. It is also essential for manufacturers to have the necessary technical expertise, experience, and infrastructure to produce steel wire rods that meet the required specifications and standards.

- Q: How is steel wire rod used in the manufacturing of wire forms for window blinds?

- Wire forms for window blinds require steel wire rod as a crucial component. This rod is chosen for its strength and durability, making it ideal for supporting the weight of blinds and enduring daily use. It is essential that the wire forms are sturdy enough to hold the blinds in place and withstand repeated opening and closing without losing their shape or functionality. To create the desired wire forms, the steel wire rod typically undergoes a series of manufacturing steps. These steps may include drawing, annealing, and coating processes. Drawing involves reducing the diameter of the rod by pulling it through dies, resulting in a thinner and more flexible wire. Annealing relieves internal stresses in the wire and enhances its ductility, making it easier to bend and shape. Coating processes may be applied to provide additional protection against corrosion or to enhance its appearance. Once the steel wire rod has been processed, it is transformed into various forms for window blinds, such as tilt rod connectors, cord connectors, and control brackets. Tilt rod connectors allow the slats in blinds to be tilted open or closed. Cord connectors secure the cords that control the raising and lowering of the blinds. Control brackets attach the blinds to the window frame and ensure stability. In summary, steel wire rod is crucial in the manufacturing of wire forms for window blinds. Its strength, durability, and versatility make it an excellent choice, ensuring the wire forms can withstand daily use and maintain functionality over time.

- Q: What are the safety precautions to be taken while working with steel wire rod?

- To minimize the risk of accidents or injuries when working with steel wire rods, it is essential to adhere to various safety measures. These include: 1. Personal Protective Equipment (PPE): It is imperative to wear appropriate PPE, such as safety glasses, gloves, and steel-toed boots, to protect oneself from potential hazards. In some cases, a hard hat might also be necessary. 2. Training: All workers should receive proper training on the safe handling and use of steel wire rods. This involves understanding the potential hazards, following safe operating procedures, and knowing emergency protocols. 3. Handling and storage: When handling steel wire rods, it is important to use correct lifting techniques and equipment to prevent strains or injuries. Store the rods in a designated area that is away from walkways or high traffic areas to avoid tripping or falling hazards. 4. Inspection: Regularly inspect steel wire rods for any defects, such as sharp edges, rust, or damage, as these can pose a safety risk. If defects are found, replace or repair the rods before further use. 5. Secure the work area: Ensure that the work area is free of clutter, debris, or any other potential tripping hazards. Keep the floor dry and clean to prevent slips and falls while working with steel wire rods. 6. Use proper tools and equipment: Utilize appropriate tools and equipment for cutting, bending, or shaping steel wire rods. Ensure that the tools are in good working condition and used correctly to prevent accidents. 7. Fire safety: Due to the potential generation of sparks when cutting or welding steel wire rods, it is crucial to have fire prevention measures in place. Make sure that fire extinguishers are easily accessible in the work area, and workers are trained on their usage. 8. Communication: Establish clear communication channels among workers to ensure that everyone is aware of the work being done and any potential hazards. Use appropriate signage or warning labels to indicate areas where steel wire rods are used or stored. By adhering to these safety precautions, the risk of accidents or injuries when working with steel wire rods can be significantly reduced, ensuring a safe working environment for all.

- Q: What are the common industry challenges for steel wire rod?

- Some common industry challenges for steel wire rod include fluctuating raw material costs, intense competition, evolving customer demands, stringent quality standards, and environmental regulations. Additionally, the steel wire rod industry often faces issues related to technological advancements, workforce training, and the need for continuous innovation to stay ahead in the market.

- Q: What are the different surface defects that can occur during wire drawing?

- During wire drawing, various surface defects can occur that may affect the quality and performance of the wire. Some common surface defects include: 1. Scratches: These are visible marks or lines on the surface of the wire caused by abrasive contact with the drawing dies or other equipment during the drawing process. 2. Grooves: Grooves are elongated depressions or channels on the wire surface that can result from excessive pressure, improper die design, or wear on the drawing dies. 3. Cracks: Cracks can occur on the wire surface due to high drawing forces, excessive strain, or improper lubrication. They can weaken the wire and reduce its mechanical strength. 4. Scale: Scale refers to the presence of oxide layers or impurities on the wire surface. It can occur due to inadequate cleaning of the incoming wire or improper heat treatment processes. 5. Flakes: Flakes are small pieces of metal that detach from the wire surface during the drawing process. They can be caused by material defects, excessive die wear, or improper lubrication. 6. Pitting: Pitting is the formation of small cavities or depressions on the wire surface, typically caused by corrosion or chemical reactions with the environment or the drawing lubricant. 7. Surface roughness: Wire drawing can result in an increase in surface roughness, which can affect the wire's appearance and reduce its performance in certain applications. To prevent or minimize these surface defects, proper selection of drawing dies, lubrication, control of drawing forces and speeds, and regular inspection and maintenance of the equipment are essential.

- Q: How is steel wire rod used in the manufacturing of suspension bridges?

- Steel wire rod is used in the manufacturing of suspension bridges primarily for the construction of suspension cables. These cables provide the primary support for the bridge deck, carrying the weight of the entire structure and distributing the load evenly. The high strength and durability of steel wire rod make it an ideal material for these cables, ensuring the bridge's stability and ability to withstand heavy loads and dynamic forces.

- Q: How are steel wire rods used in the production of brush wires?

- Brush wires are created using steel wire rods, which act as the main raw material for high-quality brush bristles. These wire rods, typically made from carbon steel, offer the strength and durability needed for brush wires. To begin the production process, the wire rods are fed into a wire drawing machine where they are pulled through dies to decrease their diameter. This step is repeated until the desired thickness is achieved. The wire is then cut into specific lengths for use as brush bristles. The mechanical properties of steel wire rods make them the preferred choice for brush wires. The carbon steel used in these rods has high tensile strength, enabling the brush bristles to withstand regular use without breaking or bending easily. Moreover, the steel wire rods provide flexibility, which is vital for creating brush bristles that can effectively clean hard-to-reach areas. After the wire drawing process, the brush wires can undergo additional treatments to enhance their performance. This may involve heat treatment to improve hardness and springiness or coating the wires with materials like nylon or brass to add functionality and durability. Once the brush wires are prepared, they can be incorporated into various types of brushes, including toothbrushes, industrial brushes, and paintbrushes. The use of steel wire rods in their production ensures that the resulting brush wires are strong, resilient, and capable of effectively performing their cleaning or scrubbing functions. In conclusion, steel wire rods play a vital role in brush wire production as they offer the necessary strength, durability, and flexibility required for brush bristles. Through a wire drawing process, these wire rods are transformed into brush bristles of the desired thickness. The use of steel wire rods ensures that the final brush wires can endure regular use and effectively clean different surfaces.

Send your message to us

Square Steel Billets Hot Sale 3SP/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords