Steel Wire Rods Hot Rolled High Carbon First Class Quality Best Seller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Wire Rod Steel for Construction Description

Wire rod steel is widely used for commercial building structure, pre-engineering buildings, machinery support structures, prefabricated structure, medium scale bridges and so on. We have supplied this product for many years and gained widespread reputation.

2.Main Features of the Wire Rod Steel for Construction

fasteners, bolts, rivets, screws,

general purpose wires,

electrode wires, industrial wires, agriculture wires,

bush wires, chain rivet wires,

detonator wire,

Umbrella ribs, upholstery wires, cycle spokes, needle wires, heald wires, staple pin Wire, safety pin wires

ACSR wires, earth wires,

tyre and hose reinforcement wires,

prestressed concrete wire, springs and rope wires,

card clothing wires,

vineyard wires,

ball bearing quality

Automobile parts like screw, fasteners, bush, spline, socket, connecting rod, shaft, gear, rivets, engine shaft, connecting rod, spindles, gears, etc.

3.Wire Rod Steel for Construction Images

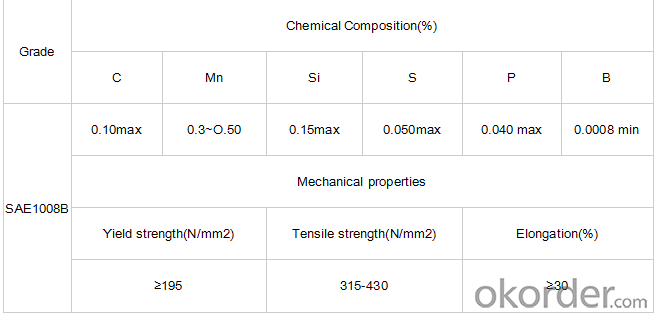

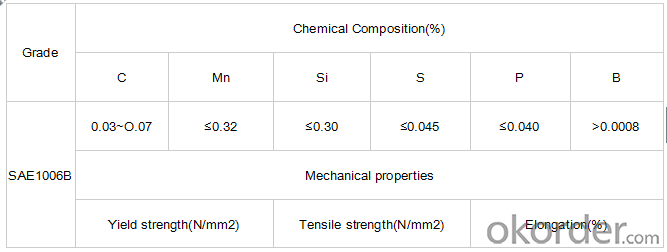

4.Wire Rod Steel for Construction Specification

5.FAQ of Wire Rod Steel for Construction

We have organized several common questions for our clients,may help you sincerely:

1.What is your minimum order quantity ?

Our MOQ is 500mt for each size. And we will consider to give more discount if you make big order like 10000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2.Please tell me the daily output and wire rod mill’s brand ?

Our daily output is 4000mt/day and our rolling mill from Germany’s SMS MEER

3.Which countries are your main sales?

Thanks to the professional international trade team, solid distribution channel and long – term cooperation customers, our market share in overseas realizes a tremendous growth, now we already became a main player in Middle East and South East Asia. Meanwhile, we are also the biggest supplier of Pre-painted galvanized steel coil in Philippines, Saudi Arabia, United Arab Emirates, Iran, Sudan etc.

- Q: What are the different types of surface coatings available for steel wire rod?

- Some common types of surface coatings available for steel wire rod include zinc coating (galvanized), polymer coatings (such as PVC or polyethylene), epoxy coatings, and organic coatings. These coatings serve various purposes such as corrosion resistance, improved aesthetics, and enhanced durability of the steel wire rod.

- Q: What are the common production processes for carbon steel wire rod?

- The common production processes for carbon steel wire rod include melting and refining of the raw materials, such as iron ore and scrap metal, in a furnace to produce molten steel. This molten steel is then continuously cast into billets or blooms, which are further processed through hot rolling, cold drawing, and heat treatment to shape and strengthen the wire rod. Finally, the wire rod is coated or galvanized to enhance its corrosion resistance and surface finish.

- Q: What are the common applications of carbon steel wire rod?

- Due to its exceptional mechanical properties and versatility, carbon steel wire rod is extensively utilized in various industries. Here, we present some common uses of carbon steel wire rod: 1. Construction: The construction industry heavily relies on carbon steel wire rod to reinforce concrete structures. It is commonly employed in the production of wire mesh, reinforcement bars, and pre-stressed concrete products. 2. Automotive: In the automotive sector, carbon steel wire rod is employed to manufacture springs, suspension components, and wire harnesses. Its remarkable strength and flexibility make it an ideal choice for these applications, ensuring reliable performance and durability. 3. Manufacturing: Carbon steel wire rod is widely employed in several manufacturing processes, including wire drawing, cold heading, and cold forging. It is commonly used to produce fasteners, bolts, nuts, and other small metal components. 4. Agriculture: The agricultural industry extensively utilizes carbon steel wire rod for applications such as fencing, vineyard trellising, and animal enclosures. With its high tensile strength and corrosion resistance, it proves to be an ideal material for outdoor use. 5. Wire Products: Carbon steel wire rod serves as the primary raw material for the production of a wide range of wire products, including cables, wire ropes, and galvanized wires. These products find applications in industries such as telecommunications, construction, and manufacturing. 6. Energy and Power: The energy and power sector relies on carbon steel wire rod for manufacturing electrical transmission and distribution lines. It provides the necessary strength and conductivity required for efficient power transmission. 7. Furniture and Household Goods: Carbon steel wire rod is utilized in the production of furniture, kitchenware, and other household goods. Its ability to be shaped into various forms provides structural support and durability to these products. In conclusion, carbon steel wire rod finds extensive applications in the construction, automotive, manufacturing, agriculture, wire products, energy and power, as well as furniture and household goods industries. Its mechanical properties, versatility, and cost-effectiveness contribute to its popularity in various applications.

- Q: What are the common applications of oil tempered and quenched steel wire rod?

- Oil tempered and quenched steel wire rod is commonly used in various applications due to its unique properties. Here are some of the common applications: 1. Springs: Oil tempered and quenched steel wire rod is extensively used in the manufacturing of springs, especially those that require high strength and durability. It provides excellent resistance to fatigue, allowing the springs to withstand repeated loading and unloading cycles without failure. 2. Mechanical parts: The high tensile strength and toughness of oil tempered and quenched steel wire rod make it suitable for various mechanical parts that require reliability and resistance to wear and tear. These parts can include bearings, gears, shafts, and other components in machinery and equipment. 3. Automotive industry: Oil tempered and quenched steel wire rod is widely employed in the automotive industry for various applications. It is used in the production of suspension springs, valve springs, clutch springs, and other components that require both strength and elasticity. 4. Construction industry: Due to its high strength and resistance to corrosion, oil tempered and quenched steel wire rod finds applications in the construction industry. It is commonly used for reinforcing concrete structures, such as pre-stressed concrete beams and columns, as well as for manufacturing various types of wire mesh and fencing. 5. Wire ropes and cables: Oil tempered and quenched steel wire rod is often used as the core material in wire ropes and cables. The unique combination of strength, flexibility, and resistance to fatigue makes it ideal for applications that involve heavy lifting, towing, or suspension, such as cranes, elevators, and suspension bridges. 6. Oil and gas industry: The oil and gas industry relies on oil tempered and quenched steel wire rod for various applications. It is used in the manufacturing of downhole tools, such as drill pipes and sucker rods, as well as for wirelines and control cables that are crucial for exploration and production operations. In summary, oil tempered and quenched steel wire rod is versatile and finds applications in a wide range of industries. Its strength, durability, and resistance to fatigue and corrosion make it a preferred choice for springs, mechanical parts, automotive components, construction materials, wire ropes, and various oil and gas industry applications.

- Q: How is the quality of steel wire rod measured?

- To assess the mechanical properties, chemical composition, and overall performance of steel wire rod, a series of tests and evaluations are conducted. These evaluations determine the quality of the rod based on several key parameters: 1. Tensile Strength: This test measures the rod's ability to withstand stress before breaking or deforming. It indicates its capacity to bear weight and resist tension. 2. Yield Strength: This test determines the stress level at which permanent deformation occurs. It indicates the rod's ability to return to its original shape after being subjected to stress. 3. Elongation: By measuring the percentage increase in length before the rod breaks under tension, this test provides insights into its ductility and ability to elongate without compromising integrity. 4. Hardness: This test assesses the rod's resistance to indentation or scratching, indicating its strength and durability. 5. Chemical Composition: The steel wire rod's composition is analyzed to ensure it meets the required standards. This involves evaluating levels of carbon, manganese, silicon, sulfur, phosphorus, and other alloying elements. 6. Surface Quality: Visual inspection and sometimes microscopic analysis are conducted to detect defects like cracks, scratches, or impurities. A smooth and clean surface is essential for optimal performance. 7. Dimensional Accuracy: The rod's diameter and length are measured to ensure they adhere to specified tolerances. Deviations from the required dimensions can impact the rod's usability in various applications. 8. Microstructure Analysis: This examination involves detailed observation of the rod's internal structure using microscopy. It helps identify abnormalities such as grain size, inclusions, or segregation that may affect its strength and performance. Through these tests and evaluations, manufacturers can ensure that steel wire rod meets the necessary quality standards and is suitable for its intended applications, such as manufacturing wire products, reinforcing materials, or springs.

- Q: How is steel wire rod used in the production of suspension springs for industrial machinery?

- Steel wire rod is used in the production of suspension springs for industrial machinery as it provides the necessary strength and durability required to withstand heavy loads and provide stable suspension. The wire rod is formed into coils and then undergoes a series of processes such as heat treatment and cold working to enhance its mechanical properties. These springs are then used in the suspension systems of machinery to absorb shocks and vibrations, ensuring smooth operation and enhanced safety.

- Q: What are the chemical properties of steel wire rod?

- The chemical properties of steel wire rod can vary depending on the specific composition of the steel. However, in general, steel wire rod is primarily made up of iron and carbon, with trace amounts of other elements such as manganese, silicon, and sulfur. The carbon content in steel wire rod plays a crucial role in determining its properties. Low carbon steel wire rod, which contains less than 0.25% carbon, is known for its ductility and ease of forming. This type of steel is commonly used in applications where flexibility and ease of manipulation are important, such as in the manufacturing of wire products, nails, and screws. On the other hand, high carbon steel wire rod, with carbon content ranging from 0.60% to 0.85%, is characterized by its strength and hardness. This type of steel is often used in applications that require high tensile strength and resistance to wear, such as in the production of springs, cables, and piano wires. Manganese is another element commonly found in steel wire rod. It is added to enhance the strength and hardenability of the steel. Manganese also improves the steel's resistance to corrosion and promotes the formation of a fine-grained microstructure, which contributes to its overall toughness. Silicon is often present in steel wire rod as a deoxidizing agent. It helps remove any impurities from the steel during the manufacturing process and improves its ability to withstand high temperatures without deformation. Sulfur is a trace element that is typically controlled in steel wire rod production. Its presence can have a detrimental effect on the steel's ductility and toughness, therefore, it is usually kept at low levels to ensure the desired mechanical properties of the wire rod. In summary, the chemical properties of steel wire rod are determined by its composition, with the carbon content being the most significant factor. Other elements such as manganese, silicon, and sulfur are also present in varying amounts and contribute to the steel's strength, hardness, ductility, and resistance to corrosion.

- Q: What are the alloying elements used in steel wire rod production?

- The alloying elements commonly used in steel wire rod production include carbon, manganese, silicon, and sometimes elements like chromium, nickel, and molybdenum for specific applications.

- Q: What is the manufacturing process of steel wire rod?

- The manufacturing process of steel wire rod involves several steps. It begins with the melting of iron ore and other materials in a blast furnace. The molten iron is then refined and converted into steel through various processes such as oxygen blowing, electric arc furnaces, or basic oxygen furnaces. Once the steel is produced, it is cast into billets or blooms, which are then hot rolled into wire rod form. The hot rolling process involves passing the billets or blooms through a series of rollers to reduce their thickness and shape them into long, continuous wire rods. After hot rolling, the wire rods are cooled, straightened, and cut into desired lengths. They may undergo additional treatments like surface finishing, heat treatment, or galvanization depending on their intended use. Finally, the wire rods are coiled and packaged for shipment to various industries where they are further processed or used directly in applications such as construction, automotive, or manufacturing.

- Q: Can steel wire rod be used in the production of wire ropes?

- Yes, steel wire rod can be used in the production of wire ropes. Steel wire rod is a semi-finished product that is typically drawn and formed into wire for various applications, including wire ropes. Wire ropes are typically made by twisting multiple strands of steel wire together to form a strong and durable rope-like structure. Steel wire rod provides the raw material needed to manufacture the individual wires that make up the strands of a wire rope. The steel wire rod is typically subjected to further processing, such as drawing and heat treatment, to achieve the desired mechanical properties and surface finish required for wire rope production. Overall, steel wire rod is an essential component in the production of wire ropes.

Send your message to us

Steel Wire Rods Hot Rolled High Carbon First Class Quality Best Seller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords