Square Steel Billets Hot Sale Q275/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of steel billet:

Our company is recognized by ISO9001:2008

1. hot rolled wire rod

2. material: Q195-235

Festures of steel billet:

1. Drawn wire specialist, your wire rod solution

2. ISO9001 Certified Mill &SGS

3. Feature: machinability, high hardness, toughness, corrosion resistant

Specifications of steel billet:

Type | Steel billet / Square steel/ Steel square bar |

Standard grade | 3SP/PS, 5SP/PS, Q195, Q235, Q255, Q275, 20MnSi etc. |

MOQ | 1000 MT |

Technique | Hot rolled |

Size | 50*50mm ~ 160*160mm |

Length | 3~12m |

Packing | Loose packing, in bundle |

Payment terms | T/T, L/C at sight, Usance L/C |

Trade terms | EXW, FOB, CFR, CIF |

Trans terms | FIO, FILO, FLT |

Inspection | Third party inspection accepted |

Delivery time | 15-30 days, according to the quantity |

Applications | carbon structural steel, wire rod, rod, deformed bars, profile steel, machine parts, and steel moulds etc . |

Note | Customized service is available (for sizes,length and chemical components etc.). |

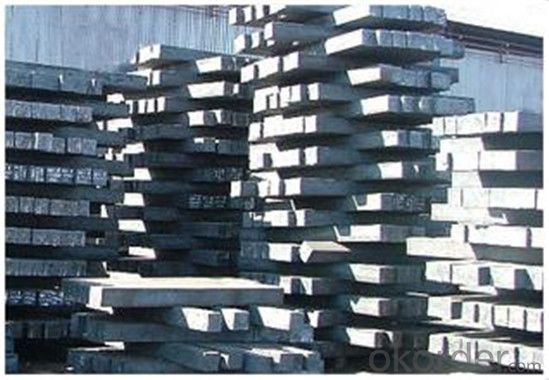

Images of steel billet:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: How are steel wire rods used in the manufacturing of nails?

- When manufacturing nails, steel wire rods play a vital role. These rods, usually made from high-quality steel known for its strength and durability, are crucial components. To begin the process, the appropriate steel wire rod is carefully selected based on the desired nail specifications. The diameter and tensile strength of the rod are chosen with great care to ensure that the final nail meets the required standards. Once the steel wire rods have been chosen, they are introduced into a nail-making machine. This machine is composed of different sections that collaborate to transform the wire rod into a nail. The first section of the machine is responsible for straightening the wire rod, ensuring its correct alignment. Then, the rod is passed to the cutting section, where it is cut into the desired length for the nail. Following that, the rod enters the forming section, where it is shaped into the nail's basic structure. This section employs a combination of mechanical force and heat to mold the wire rod. After the forming process, the nail goes through a series of rollers and dies to refine its shape and enhance its strength. These rollers and dies give the nail its characteristic head, shank, and point. Lastly, the nails are cooled and subjected to quality control inspections. Any defective nails are discarded, while the acceptable ones are collected and packaged for distribution. In conclusion, steel wire rods are indispensable in the manufacturing of nails. They provide the necessary raw material to create sturdy and reliable nails. The strength and durability of steel make it an ideal material for nails, enabling them to withstand the pressures and forces they will encounter during use.

- Q: What are the standard lengths available for steel wire rod?

- Steel wire rods are available in a variety of standard lengths, which are typically measured in feet or meters. The most common standard lengths for steel wire rods range from 6 to 12 meters (20 to 40 feet). However, it is important to note that the specific standard lengths of steel wire rods can vary depending on the manufacturer and the intended application. Additionally, custom lengths can often be requested and produced to meet specific project requirements.

- Q: How is steel wire rod used in the manufacturing of wire rope assemblies for lifting equipment?

- Steel wire rod is used in the manufacturing of wire rope assemblies for lifting equipment as it serves as the primary material for constructing the individual wires that make up the rope. The steel wire rod is carefully selected for its high tensile strength and durability, ensuring the wire rope has the necessary strength and resilience to safely lift and support heavy loads. The wire rod is first drawn into the desired diameter and then twisted and braided together to form the wire rope, which is then further processed and assembled with fittings and hardware to create the complete wire rope assembly used in lifting equipment.

- Q: How does steel wire rod behave under different temperature conditions?

- Steel wire rod behaves differently under different temperature conditions. At lower temperatures, steel wire rod tends to become more brittle and prone to fracturing. This is because the cold temperatures cause the metal to contract, reducing its ductility and making it more susceptible to breaking under stress. On the other hand, at higher temperatures, steel wire rod becomes more malleable and easier to bend or shape. This is due to the expansion of the metal as it heats up, which increases its ductility and allows it to withstand greater deformation without fracturing. However, it is important to note that extreme temperatures can have adverse effects on steel wire rod. At extremely low temperatures, such as those found in cryogenic environments, the steel may undergo a phase transformation known as the ductile to brittle transition, where it becomes extremely brittle and prone to sudden failure. Similarly, at extremely high temperatures, steel wire rod may lose its strength and integrity, as the elevated temperatures can cause the metal to soften and deform. The exact temperature at which this occurs depends on the specific type of steel and its composition. In summary, steel wire rod behaves differently under different temperature conditions. It becomes more brittle and prone to fracturing at lower temperatures, while it becomes more malleable and easier to shape at higher temperatures. However, extreme temperatures can have detrimental effects on the steel's properties, leading to brittleness at low temperatures and loss of strength at high temperatures.

- Q: How is steel wire rod used in the manufacturing of wire for medical devices?

- Steel wire rod is used in the manufacturing of wire for medical devices as it serves as the raw material for producing high-quality wire. This rod is typically drawn through a series of dies to achieve the desired diameter and shape of the wire used in medical devices such as catheters, sutures, and orthopedic implants. The steel wire rod's strength, flexibility, and corrosion resistance make it an ideal material for ensuring the reliability and durability of these critical medical instruments.

- Q: How is the microstructure of steel wire rod analyzed?

- The microstructure of steel wire rod is typically analyzed using various techniques such as optical microscopy, electron microscopy (scanning electron microscopy or transmission electron microscopy), and X-ray diffraction. These techniques allow for the examination of the grain structure, inclusion content, and other microstructural features of the steel wire rod.

- Q: How is steel wire rod used in the production of suspension springs for aircraft?

- Steel wire rod is used in the production of suspension springs for aircraft as it provides the necessary strength and flexibility required for supporting the weight of the aircraft and absorbing shocks during landing and takeoff. The wire rod is shaped and coiled into springs, which are then incorporated into the suspension system to ensure stable and smooth operations.

- Q: What are the different types of steel wire rod coatings used for high-temperature resistance?

- There are several types of steel wire rod coatings that are used for high-temperature resistance. These coatings are designed to protect the steel wire rod from oxidation, corrosion, and other forms of damage that can occur at elevated temperatures. One common type of coating used for high-temperature resistance is zinc. Zinc coatings provide excellent corrosion protection at high temperatures and are often used in applications where the steel wire rod will be exposed to extreme heat. Another type of coating that is commonly used for high-temperature resistance is aluminum. Aluminum coatings can withstand high temperatures and provide a barrier against oxidation and corrosion. Additionally, there are specialized coatings that are specifically designed for high-temperature resistance. These coatings often contain materials such as ceramic, refractory metals, or silicone-based compounds. Ceramic coatings, for example, are known for their ability to withstand extremely high temperatures and provide excellent thermal insulation. Refractory metal coatings, such as tungsten or molybdenum, are used in applications where the steel wire rod will be exposed to extremely high temperatures and harsh environments. Silicone-based coatings are known for their heat resistance and can provide a protective barrier against oxidation and corrosion. The choice of coating depends on the specific application and the desired level of high-temperature resistance. It is important to consider factors such as the operating temperature, the environment, and the level of protection required when selecting a coating for steel wire rod used in high-temperature applications.

- Q: What are the different types of tests performed on steel wire rod?

- There are several types of tests performed on steel wire rod to ensure its quality and suitability for various applications. These tests include: 1. Chemical Composition Analysis: This test determines the percentage of different elements present in the steel wire rod, such as carbon, manganese, silicon, sulfur, phosphorus, and other trace elements. It helps to ensure that the steel meets the required specifications. 2. Tensile Strength Test: This test measures the ability of the steel wire rod to withstand tension or pulling forces without breaking. It determines the maximum load the rod can bear before it fractures, providing crucial information about its strength and durability. 3. Elongation Test: This test determines the percentage increase in length the steel wire rod undergoes before it breaks under tension. It helps to assess the ductility and malleability of the rod, indicating its ability to withstand deformation without fracturing. 4. Hardness Test: This test measures the resistance of the steel wire rod to indentation or scratching. It provides an indication of the material's strength and ability to resist wear and tear. 5. Microstructure Analysis: This test involves examining the microstructure of the steel wire rod under a microscope. It helps to identify any structural anomalies, such as grain size, presence of inclusions, and uniformity, which can affect the rod's mechanical properties. 6. Surface Inspection: This test involves visually inspecting the surface of the steel wire rod for any defects, such as cracks, scratches, or surface irregularities. It ensures that the rod meets the required visual quality standards. 7. Dimensional Inspection: This test verifies the dimensional accuracy and tolerances of the steel wire rod, such as diameter, length, and straightness. It ensures that the rod meets the specified dimensional requirements for its intended application. 8. Corrosion Resistance Test: This test evaluates the steel wire rod's ability to resist corrosion when exposed to different environmental conditions. It helps to determine the rod's suitability for applications where corrosion resistance is critical. By performing these tests, manufacturers can ensure that the steel wire rod meets the necessary quality standards and is suitable for use in various industries, including construction, automotive, manufacturing, and infrastructure.

- Q: What are the different types of packaging options available for steel wire rod?

- The packaging options for steel wire rod vary, depending on factors such as size, weight, intended use, and buyer or manufacturer preferences. Coil packaging is a common option for smaller diameter wire rods. It involves coiling the wire rod into a circular shape and tightly securing it with plastic or steel straps. Coils are convenient for transportation and storage. Bundle packaging, on the other hand, is suitable for larger diameter wire rods. This method involves bundling multiple pieces of wire rod together and tightly binding them with steel straps. Bundles provide stability during transportation and handling. In addition to coils and bundles, steel wire rod can also be packaged in wooden crates or pallets. This method offers extra protection during transportation and is suitable for both small and large diameter wire rods. Wooden packaging is often preferred for long-distance shipping or extended storage. Furthermore, manufacturers may offer custom packaging options to meet specific requirements. This could involve using special wrapping materials, implementing additional protective measures, or creating unique packaging designs. Overall, the various packaging options available for steel wire rod ensure safe and efficient handling, transportation, and storage, while also catering to the specific needs of buyers and manufacturers.

Send your message to us

Square Steel Billets Hot Sale Q275/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords