Square Steel Billets Hot Sale Q235B/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of steel billet:

Our company is recognized by ISO9001:2008

1. hot rolled wire rod

2. material: Q195-235

Festures of steel billet:

1. Drawn wire specialist, your wire rod solution

2. ISO9001 Certified Mill &SGS

3. Feature: machinability, high hardness, toughness, corrosion resistant

Specifications of steel billet:

Type | Steel billet / Square steel/ Steel square bar |

Standard grade | 3SP/PS, 5SP/PS, Q195, Q235, Q255, Q275, 20MnSi etc. |

MOQ | 1000 MT |

Technique | Hot rolled |

Size | 50*50mm ~ 160*160mm |

Length | 3~12m |

Packing | Loose packing, in bundle |

Payment terms | T/T, L/C at sight, Usance L/C |

Trade terms | EXW, FOB, CFR, CIF |

Trans terms | FIO, FILO, FLT |

Inspection | Third party inspection accepted |

Delivery time | 15-30 days, according to the quantity |

Applications | carbon structural steel, wire rod, rod, deformed bars, profile steel, machine parts, and steel moulds etc . |

Note | Customized service is available (for sizes,length and chemical components etc.). |

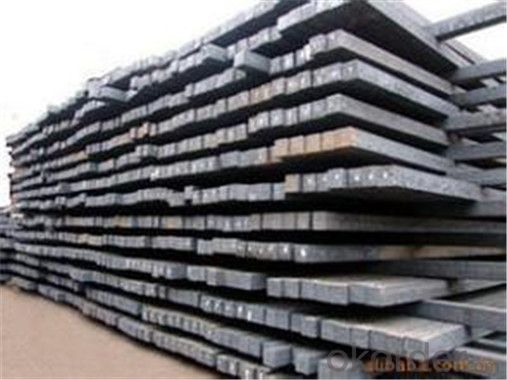

Images of steel billet:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: How are steel wire rods used in the manufacturing of strings for musical instruments?

- Musical instrument strings rely heavily on steel wire rods to provide strength, durability, and the ability to withstand tension. These rods serve as the core material for the inner structure of strings, ensuring their robustness. To craft musical instrument strings, steel wire rods undergo a series of meticulous processes. Initially, they are carefully chosen based on their desired characteristics, such as flexibility and tensile strength. Subsequently, these rods are drawn through a set of dies to reduce their diameter and increase their length, a process known as drawing. After drawing, the steel wire rods often go through additional steps to enhance their performance. These steps may include annealing, which entails subjecting the rods to specific temperatures and gradually cooling them to enhance flexibility and eliminate internal stresses. Furthermore, the rods might undergo surface treatments like electroplating or coating to prevent corrosion and improve playability. Once the steel wire rods have undergone the necessary processing, they are ready to be transformed into strings. Typically, the rods are wound tightly around a core material, such as nylon or gut, to achieve the desired thickness and tension for each string. This winding process ensures that the steel wire remains securely in place, providing the necessary strength and stability. Utilizing steel wire rods in the manufacturing of musical instrument strings offers numerous advantages. Steel produces a bright and clear tone, making it suitable for various instruments such as guitars, pianos, and violins. Additionally, these rods offer exceptional durability and resistance to breakage, enabling the strings to withstand the constant tension and impact of playing. In conclusion, steel wire rods hold a vital role in the manufacturing of musical instrument strings. Their strength, flexibility, and durability make them an ideal material for the inner structure of strings, while also contributing to the instrument's unique sound and playability.

- Q: What are the common defects that can occur during the processing of steel wire rod?

- Some common defects that can occur during the processing of steel wire rod are surface cracks, internal voids or inclusions, uneven dimensions, and incorrect chemical composition.

- Q: What are the different types of steel wire rod cooling methods?

- There are several different types of steel wire rod cooling methods, including air cooling, water cooling, and controlled cooling.

- Q: What are the different surface defects that can lead to failure in steel wire rod?

- Some of the different surface defects that can lead to failure in steel wire rod include cracks, pits, scratches, and surface decarburization. These defects can weaken the wire rod, reducing its strength and leading to potential failure during use.

- Q: How is steel wire rod manufactured?

- Steel wire rod is manufactured through a process called hot rolling, which involves passing a billet or a slab of steel through a series of rolling mills. These mills compress and shape the steel into a long, continuous rod with a specific diameter. The rod is then cooled and coiled, ready to be used in various applications such as construction, automotive, and manufacturing industries.

- Q: What are the typical mechanical properties of steel wire rod?

- The mechanical properties of steel wire rod can vary depending on the grade and composition of the steel used. However, there are commonly observed general mechanical properties in steel wire rods. Tensile strength is a crucial mechanical property of steel wire rod. Steel wire rods are known for their high tensile strength, which is the maximum stress or load they can withstand before breaking. The grade and processing of the steel determine the tensile strength, which can range from a few hundred megapascals (MPa) to several thousand MPa. Ductility is another important mechanical property of steel wire rod. Ductility refers to the ability of a material to undergo plastic deformation without fracturing. Steel wire rods have high ductility, allowing them to be easily shaped without breaking. This property is essential for applications that involve bending, twisting, or pulling the wire rod. Steel wire rods also have good toughness, which means they can absorb energy and resist fracture under impact or sudden loads. This makes them suitable for applications in industries like construction, automotive, or machinery. Moreover, steel wire rods have excellent corrosion resistance, especially when they are coated or treated to enhance their protective properties. This resistance is crucial in environments with harsh conditions or corrosive substances. Additionally, steel wire rods have good thermal and electrical conductivity, making them suitable for use in the electrical and electronics industries. It's worth noting that the specific mechanical properties of steel wire rods can be modified through processes like heat treatment, cold working, or alloying. Different grades of steel wire rods may have optimized mechanical properties for specific applications. In summary, steel wire rods possess high tensile strength, good ductility, toughness, corrosion resistance, and thermal and electrical conductivity. These properties make them versatile and widely used in various industries.

- Q: How does the magnetic properties of steel wire rod vary with different grades?

- The magnetic properties of steel wire rod can vary significantly with different grades. The magnetic behavior of steel is primarily determined by its composition and microstructure, which can be altered in various ways to achieve different grades of steel. In general, steel wire rods with a higher carbon content tend to have lower magnetic properties. This is because carbon atoms disrupt the alignment of magnetic domains within the steel, reducing its overall magnetic strength. Therefore, low carbon steel grades, such as AISI 1006 or SAE J403 Grade 1006, typically exhibit weaker magnetic properties. On the other hand, steel wire rods with higher alloying elements, such as chromium, nickel, or manganese, tend to have increased magnetic strength. These alloying elements can influence the microstructure of the steel, promoting the formation of magnetic domains and enhancing the overall magnetization. Stainless steel grades, which contain a significant amount of chromium and nickel, often exhibit stronger magnetic properties compared to low carbon steel grades. It is important to note that while certain steel grades may have inherently stronger or weaker magnetic properties, the specific processing and heat treatment techniques applied during the manufacturing of wire rods can also influence the magnetic behavior. Different heat treatments can alter the microstructure and precipitate various phases within the steel, thereby affecting its magnetic properties. In summary, the magnetic properties of steel wire rod vary with different grades due to differences in composition, alloying elements, and microstructure. Steel grades with higher carbon content generally exhibit weaker magnetic properties, while those with higher alloying elements tend to have increased magnetization. Additionally, the specific processing and heat treatment techniques used during manufacturing can also impact the magnetic behavior of steel wire rod.

- Q: How is steel wire rod used in the production of wire mesh reinforcement?

- Steel wire rod is used in the production of wire mesh reinforcement by being drawn through a series of dies to reduce its diameter and increase its length. This process, known as cold drawing, results in a strong and flexible wire that is then woven or welded together to create wire mesh reinforcement. The steel wire rod serves as the foundation for the wire mesh, providing strength and stability to the structure it supports.

- Q: How is steel wire rod used in the manufacturing of wire forms for playground equipment?

- Steel wire rod is an essential component in the manufacturing process of wire forms for playground equipment. The wire rod is typically made from high-quality steel and is available in various diameters to suit different requirements. To create wire forms for playground equipment, the steel wire rod goes through a series of manufacturing steps. First, it is fed into a machine that cleans and removes any impurities from the surface. This ensures that the wire is clean and ready for further processing. Next, the wire rod is passed through a drawing machine, which reduces its diameter to the desired size. This process involves pulling the wire rod through a series of dies, gradually decreasing its diameter and increasing its length. This drawing process not only shapes the wire but also improves its strength and durability. After the wire has been drawn to the desired diameter, it is then annealed to relieve any internal stress and enhance its malleability. This makes it easier to bend and shape the wire into the desired forms for playground equipment. Once the wire has been annealed, it is ready for the forming process. During this stage, the wire is bent, twisted, and shaped using specialized machines and tools. These wire forms can include various components such as hooks, loops, spirals, and curves, depending on the specific design requirements of the playground equipment. The formed wire is then subjected to a heat treatment process known as quenching and tempering. This process further enhances the wire's strength and durability, making it capable of withstanding the rigors of playground use. Finally, the wire forms are coated with a protective finish to prevent corrosion and improve their lifespan. This coating can be a variety of materials, such as galvanization or powder coating, depending on the specific requirements of the playground equipment. Overall, steel wire rod is an integral part of the manufacturing process for wire forms used in playground equipment. Its strength, durability, and malleability make it an ideal material for creating safe and reliable wire forms that can withstand the demands of playground use.

- Q: How is steel wire rod used in the production of wire for brush bristles?

- Steel wire rod is an essential material in the production of wire for brush bristles. Wire rod serves as the primary raw material that is used to manufacture the wires needed for brush bristles. To begin the production process, steel wire rod is first selected based on its specific properties, such as strength, flexibility, and durability. The chosen rod is then processed through a series of manufacturing steps to transform it into the desired wire for brush bristles. The first step involves drawing the steel wire rod through a series of dies, which gradually reduce its diameter while increasing its length. This process is known as wire drawing and is repeated multiple times to achieve the desired thickness and strength of the wire. After wire drawing, the wire is further processed to improve its properties. This may include heat treatment to enhance its strength and flexibility, or surface treatments like galvanization or coating to provide corrosion resistance. Once the wire has undergone these treatments, it is then cut into lengths suitable for brush bristles. At this stage, the wire can be further manipulated to develop specific brush bristle characteristics. For example, the wire may be twisted or crimped to enhance its cleaning or brushing capabilities. Finally, the wire is attached to the brush base or handle to complete the production of brush bristles. The wires are typically secured using specialized machinery or techniques such as stapling or binding. In summary, steel wire rod plays a crucial role in the production of wire for brush bristles. It serves as the basic material that undergoes various manufacturing processes, including wire drawing, heat treatment, and surface treatments, to transform it into the required wire for brush bristles.

Send your message to us

Square Steel Billets Hot Sale Q235B/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords