Spot 20# seamless steel tube high pressure seamless steel tube Q345B seamless steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

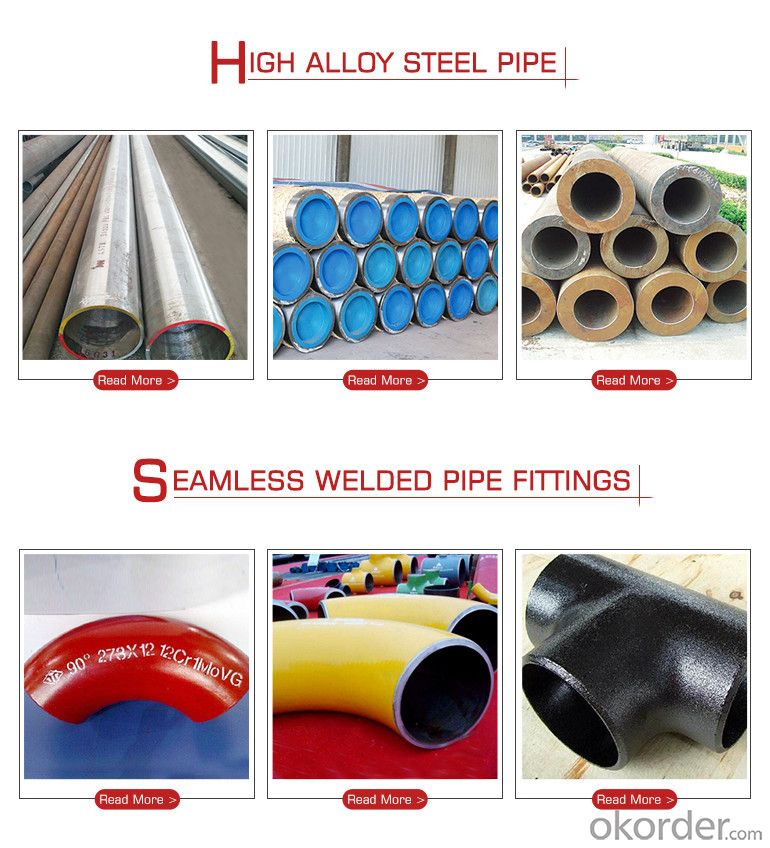

Main materials :10#, 20#, 35#, 45#, 20G, 40Cr, 20Cr, 16mn-45mn, 27SiMn, Cr5Mo, 12CrMo(T12), 12Cr1MoV, 12Cr1MoVG, 10CrMo910, 15CrMo, 35CrMo, 40CrMo, etc.

1. Seamless tubes for construction (GB/ t8162-2008) are seamless tubes for general construction and mechanical construction.

2. Seamless pipe for fluid transportation (GB/ t8163-2008) is a normal seamless pipe for the transportation of water, oil, gas and other fluids.

3. Seamless tube for low and medium pressure boiler (gb3087-2008) is a kind of seamless tube for hot rolling and cold drawing (rolling) of excellent carbon structure steel, which is used for making all kinds of superheated steam tube, boiling water tube, superheated steam tube for locomotive boiler, big pipe, small pipe and arch brick.

4. Seamless tube for high-pressure boiler (gb5310-2008) is a seamless tube of excellent carbon steel, alloy steel and stainless heat-resistant steel for the heating surface of water-tube boiler with high pressure and above pressure.

5. High pressure seamless tubes for fertilizer equipment (gb6479-2000) are excellent carbon structural steel and alloy steel seamless tubes suitable for chemical equipment and pipelines with operating temperature of -40~400℃ and working pressure of 10~30Ma.

6. Seamless tubes for petroleum cracking (gb9948-2006) are seamless tubes for furnace tubes, heat exchangers and pipelines used in petroleum refineries.

7. The steel pipe for geological drilling (yb235-70) is the steel pipe for core drilling in geological part, which can be divided into drill pipe, drill collar, core pipe, casing pipe and deposition pipe, etc.

8. Seamless pipe for diamond core drilling (gb3423-82) is a seamless pipe for drilling drill pipe, core rod and casing for diamond core drilling.

9. The oil drilling pipe (yb528-65) is a seamless pipe with internal or external thickening at both ends for oil drilling.

10. Seamless carbon steel tubes for ships (gb5312-85)

11.Seamless steel tubes (GB/ t18984-2003) for cryogenic piping are used for -45℃ ~ -195℃ cryogenic pressure vessel piping and cryogenic heat exchanger piping

company introduction:

Our company is a new force established by the pipe industry group founded in the 1980s. Relying on a large number of core technologies accumulated by the group, as well as strict quality control, physical and chemical testing, it carries out professional pipe fitting management in strict accordance with various standards.Products are widely used in petroleum, petrochemical, chemical, thermal power, boiler, four pipelines, fertilizer, aviation nuclear power, metallurgy, shipbuilding, machinery and military fields.

The main products of our company mainly include elbow, elbow, tee, reducing pipe, pipe cap, sharp elbow, flange, socket, forged pipe fittings and difficult pipe fittings.In addition, our company always has alloy steel tubes, seamless steel tubes for high-pressure boilers.Middle and low pressure boiler tube, low temperature steel tube, pipeline steel tube and so on after 10,000 tons.

- Q: What is the difference between carbon steel and stainless steel pipes?

- The main difference between carbon steel and stainless steel pipes lies in their composition and corrosion resistance. Carbon steel pipes are primarily made of iron and carbon, while stainless steel pipes contain iron, carbon, and a minimum of 10.5% chromium. This chromium content in stainless steel provides excellent corrosion resistance, making it more suitable for applications where pipes may come in contact with moisture or corrosive substances. Carbon steel pipes, on the other hand, are more cost-effective and commonly used in applications where corrosion resistance is not a primary requirement.

- Q: What are the different methods of coating steel pipes?

- There are several different methods of coating steel pipes, including fusion bonded epoxy (FBE) coating, liquid epoxy coating, polyurethane coating, and three-layer polyethylene (3LPE) coating.

- Q: Can steel pipes be used for irrigation systems?

- Yes, steel pipes can be used for irrigation systems. They are strong, durable, and resistant to corrosion, making them suitable for transporting water and withstanding outdoor conditions. However, it is important to ensure proper insulation and maintenance to prevent any potential rust or degradation.

- Q: How do you calculate the pipe pressure drop for steel pipes?

- To calculate the pipe pressure drop for steel pipes, you can use the Darcy-Weisbach equation or the Hazen-Williams equation. The Darcy-Weisbach equation is generally more accurate but requires more information. It takes into account the pipe diameter, length, roughness, fluid flow rate, and fluid properties such as viscosity and density. The equation is as follows: ΔP = (f * L * ρ * V^2) / (2 * D) Where: ΔP is the pressure drop f is the friction factor (which can be determined using Moody's chart or by using empirical equations such as the Colebrook-White equation) L is the pipe length ρ is the fluid density V is the fluid velocity D is the pipe diameter The Hazen-Williams equation is a simplified version that is commonly used for water flow calculations. It is less accurate but easier to use. The equation is as follows: ΔP = K * Q^1.85 / (C^1.85 * d^4.87) Where: ΔP is the pressure drop K is the Hazen-Williams coefficient (which depends on the pipe material and roughness) Q is the flow rate C is the Hazen-Williams roughness coefficient d is the pipe diameter It's important to note that these equations provide an estimate of the pressure drop, and actual conditions may vary due to factors such as fittings, bends, and valves in the pipe system. Additionally, it's crucial to ensure that the units used in the equations are consistent (e.g., using SI units or US customary units).

- Q: How are steel pipes used in the construction of oil storage tanks?

- Steel pipes are commonly used in the construction of oil storage tanks for several purposes. Firstly, they are used to create the framework and structure of the tank, providing strength and durability to support the weight of the stored oil. Additionally, steel pipes are used for the internal and external piping systems of the tank, facilitating the transportation of oil to and from the tank. Finally, steel pipes are also employed for the ventilation and drainage systems of the tank, ensuring proper airflow and drainage to prevent any potential hazards or damage.

- Q: What are the different types of pipe coatings used for corrosion protection?

- There are several types of pipe coatings used for corrosion protection, including epoxy coatings, polyethylene coatings, polyurethane coatings, and zinc coatings. Each type of coating offers specific advantages and is chosen based on factors such as the type of corrosive environment, the desired level of protection, and the budget constraints.

- Q: What are the advantages of using steel pipes?

- There are several advantages of using steel pipes. Firstly, steel pipes are extremely durable and have a long lifespan, making them a cost-effective choice for various applications. Secondly, steel pipes have high resistance to corrosion, making them suitable for use in harsh environments and underground applications. Thirdly, steel pipes have high strength and can withstand heavy loads, making them ideal for transporting fluids and gases under high pressure. Additionally, steel pipes are versatile and can be easily welded, threaded, or bent to fit specific requirements. Lastly, steel pipes are recyclable, making them an environmentally friendly choice.

- Q: Can steel pipes be used for offshore applications?

- Yes, steel pipes can be used for offshore applications. Steel pipes are commonly used in offshore industries due to their durability, strength, and resistance to corrosion. Offshore applications such as oil and gas exploration, drilling, production, and transportation of fluids and gases often require the use of steel pipes. These pipes are designed to withstand harsh and corrosive environments found in offshore locations, including exposure to saltwater, extreme temperatures, and high pressure. Additionally, steel pipes can be manufactured to meet specific requirements for offshore projects, including size, thickness, and material grade, to ensure safety and reliability. Overall, steel pipes are a reliable and widely used choice for offshore applications.

- Q: What is the difference between hot-finished and cold-finished steel pipes?

- Hot-finished steel pipes are produced by heating the steel to a high temperature and then passing it through a series of rollers to give it the desired shape and size. This process results in a smooth surface finish and improved mechanical properties. On the other hand, cold-finished steel pipes are produced by cold drawing the steel through a die, resulting in a smaller diameter and improved dimensional accuracy. Cold-finished pipes have a smoother surface finish and tighter tolerances compared to hot-finished pipes.

- Q: Do steel pipes require maintenance?

- Yes, steel pipes do require maintenance. While steel pipes are durable and long-lasting, they can still be subject to wear and tear over time. Regular maintenance is important to ensure their optimal performance and prolong their lifespan. One important aspect of maintenance is inspecting the pipes for any signs of damage or corrosion. Steel pipes can be vulnerable to rust and corrosion, especially in environments with high humidity or exposure to water. Regular inspections allow for early detection of any issues, which can prevent more significant damage and costly repairs in the future. Another aspect of maintenance is cleaning the pipes. Over time, steel pipes can accumulate debris, sediment, or mineral deposits. These build-ups can restrict the flow of fluids or affect the quality of the transported materials. Regular cleaning helps to remove these obstructions and maintain the efficiency of the pipes. Depending on the application, steel pipes may also require periodic lubrication or coating. This helps to reduce friction, prevent corrosion, and enhance the pipes' durability. Lubricants and coatings can be applied during maintenance to ensure the pipes continue to function smoothly and resist corrosion. Overall, regular maintenance of steel pipes is essential to maximize their performance, prevent damage, and prolong their lifespan. By investing time and effort in maintenance, potential issues can be identified and addressed early on, ultimately saving time and money in the long run.

Send your message to us

Spot 20# seamless steel tube high pressure seamless steel tube Q345B seamless steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords