Splice Routel AJ13

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

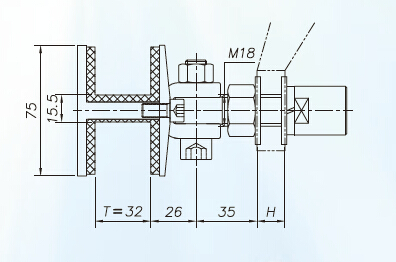

Product Name | Splice Routel AJ13 |

Material | Stainless Steel 304/316. |

Finish | Natural |

Glass thickness | 32mm |

Bolt Size | M18 |

Max. axial bearing capacity | 6000N |

Max. Radial Bearing capacity | 2500N |

Adjustable angle | ±10 degree |

Min Order | 100piece/ pieces |

Packing | Inner Box + Carton Box |

Supply capacity | 100000 piece/ pieces per month |

Delivery time | 20~35 days after receipt of down payment |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Pictures:

Splice Routel AJ13

- Q: What is the difference between the price of the pick up claw?

- Material 201,304,316, from time to good, the most commonly used is 304. The larger the size, of course, the price is smaller than the size of the expensive

- Q: A set of curtain wall point of the stainless steel access to the claws, including what?

- A set of curtain wall accessories include: such as four claws included, a four paw claw pieces, a adapter base, four split joints, to form a set, in the market are generally complete sets of quotes, but the market The price is expensive outrageous

- Q: Curtain wall materials, hardware accessories which

- The curtain wall is the external wall of the building, not load, like the curtain hanging up, it is also known as the "curtain wall", is a modern large and high-rise buildings with decorative effect of light wall. By the panel and the supporting structure of the system can be relative to the main structure of a certain displacement or have their own ability to deformation, do not assume the role of the main structure of the building outside the envelope or decorative structure.

- Q: What are the specifications of the curtain wall

- 1: 200 series; 2: 220 series; 3: 250 series; 4: 300 series;

- Q: The construction of the people say to make a certain slope, because the rain to the direction of their own home to the flow of the station Will the beam be loaded with I-beam? Workers say 50 * 100 square tube on the line

- Slope is necessary, is conducive to drainage, more importantly, in order to ensure that the top surface of the ash can be washed away with the water, the slope should not be too small. Load-bearing rod (beam, column) according to the structure according to the standard calculation to determine, as long as the satisfaction on the line. In general, the use of aluminum alloy structure, the latter there is no anti-corrosion problem will be better, if not a large structure, it is recommended to use aluminum alloy material (the surface of the use of spray color selection, corrosion good weather). The general home decoration to do the sun room area will not be too large, aluminum alloy structure is preferred. Most people always think that steel structure than aluminum alloy structure is safe, it is a misunderstanding, the aircraft is mainly used in aluminum alloy material, so the material is not a problem, the key lies in the choice of section of the bar. Aluminum alloy material is easy to form, according to the need to open a model, select a large range, and aluminum structure can make a variety of sunny room modeling, beautiful and practical!

- Q: Steel glass canopy glass is tiled or split jaws good

- Light steel glass canopy glass can also be used to strengthen the glass, including light weight, wind load, snow load and live load

- Q: How is the glass curtain wall attached to the steel frame fixed on the steel frame

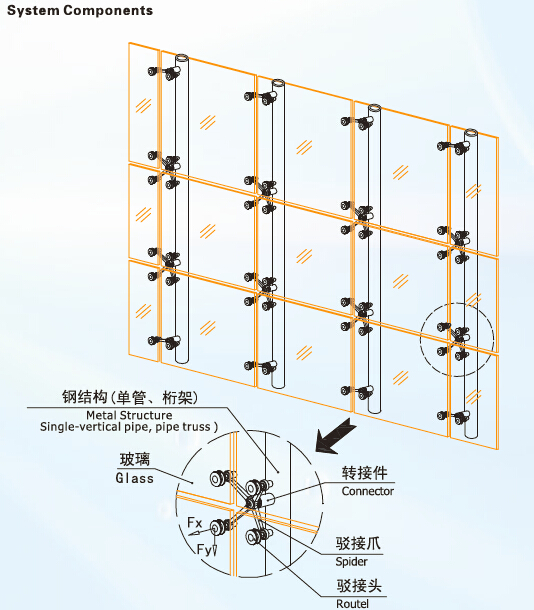

- Steel structure point curtain wall cylindrical adapter seat welded to the steel structure, the splicing claw screw to the adapter seat, the joint and then fixed to the splicing claw

- Q: Curtain wall windows fixed glass with what accessories

- Conventional shape of the split claws: four claws, three claws, two claws 90 degrees, two claws 180 degrees, long claws, short claws, K-type claws,

- Q: 304 stainless steel splicing claws the price is how much, what quality and cheap manufacturers

- Also depends on what size you want. Prices in the tens to hundreds of range. Last month, our company set a number of split claws, manufacturers called Jiangsu Jie Chen, dozens of dollars a set, okay, no rust.

- Q: Curtain wall panel installation control points which

- The splicing jaws serve as an important accessory to the glass curtain wall, which plays an important role in the connection of the glass curtain wall. The mechanical properties are particularly important by passing the load to the steel structure or other body structure through the splice joint. Of the installation staff, in the point of the installation of the curtain wall accessories need to master more technical and knowledge points. Introduction is the stainless steel splicing jaws when you need to pay attention to the installation of some of the details, hoping to help everyone. The stainless steel splicing pawl-type curtain wall fittings are composed of splice joints, splicing claws, adapter parts and so on. The splicing jaws are mainly used as supporting link joints and pass the load to the fixed supporting structure system, which is connected with the glass curtain wall An important accessory. With the impact of the curtain wall industry, in order to achieve the best effect of the use of stainless steel splicing claws, construction details are essential, and today to introduce some of the details of the construction of the splicing claws and the need to pay attention to the problem. The first is the preparation before the installation.

Send your message to us

Splice Routel AJ13

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords