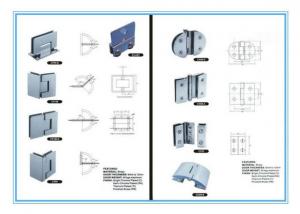

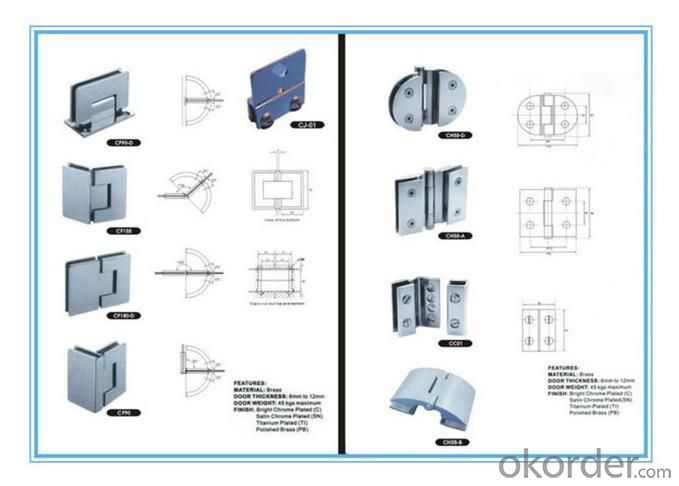

Stainless Steel Glass Clamp of Building Hardware with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Pieces pc

- Supply Capability:

- 1200 Pieces Per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of The Stainless Steel Glass Clamp Of Building Hardware With High Quality

1,Material: Stainless Steel

2,Usage: Glass Clamp forbuilding

3,Standard or Nonstandard: Standard

4,size and thickness:custom

1. Main specifications of The Stainless Steel Glass Clamp Of Building Hardware With High Quality

Process | Lost wax casting(Silica method) |

Key specification |

1.Material: stainless steel 304 316 316L

2.Standard: ASTM\DIN\BS\JIS

3.Surface finish: stain polished or mirror polished

4.Weight: about 200-300grams

5.Useful: 8-20mm width glass |

production facility | 1.Casting facility: wax injector, paint mixer, medium-frequency induction furnace, box resistance furnace, cutting head machine, shot-blasting machine, sand-blasting machine, pickling line. 2.Machining facility: CNC machine, linear cutting machine, NC milling machine, polishing machine. |

Heat treatment | Solid solution. |

Testing facility | spectrometer, tensile test machine, hardness test machine, mircoscope. |

2.About The Stainless Steel Glass Clamp Of Building Hardware With High Quality

(1)We can produce your goods according to your drawings, also can do complicated products.

(2)We can do CNC machining and many kinds surface treatment, just tell me your requirements on physical properties.

3. About quality of The Stainless Steel Glass Clamp Of Building Hardware With High Quality

1)Our products are tested by spectrometer before pouring, so just forget the material requirements.

2)Our spectrometer is introduced from Germany in 2007.

3)Our workers test each piece before store it.

4.About Factory

(1)Experience:We have 16 years experience in casting and take the lead in passing ISO9001:2000 among the same industry.

(2)Good After Sales Service:We have advanced facilities to guarantee our product's quality and any small problem happening of our products will be solved at the most prompt time.

5.Our market:

Popular in the Europe and America, also in Janpan and South Korea.

- Q: The installation method of the splicing jaws

- Splicing claw installation method is not difficult, a few things on the assembly under OK.

- Q: What is the connection between the glass room and the stainless steel?

- Use a shadowless glue to paste the steel cake and then screw the lock on it

- Q: Afraid to stand under the building with a glass curtain wall Today to the digital square, walked, suddenly heard a sound, and then a look at the front of the meter on the second floor of the glass split on the second floor, just under the two people passing. A time screaming again and again. Sent to the nearby hospital, blood flow all the way ... ... I also decorated the company for two years, really do not understand why so many people like glass curtain wall now. Personally feel that it can only look at the top, but also unsafe (old in the accident), and dirty (high difficult to clean up).

- Now people like simple, and the light is very good, you can save energy, if it is the wall, then how much to waste electricity Although he has light pollution, but still like

- Q: The construction of the people say to make a certain slope, because the rain to the direction of their own home to the flow of the station Will the beam be loaded with I-beam? Workers say 50 * 100 square tube on the line

- Recommendation: do the sun room must choose a regular company, need to have the design and calculation capabilities, through the design of the design calculation to ensure the safety of the structure, which is necessary. There are regular company material control will be better, construction and installation will be more standardized after use, with the rest assured.

- Q: What are the metal members connecting the glass and the glass ribs in the glass curtain wall?

- Called the claws. The splicing jaws are mainly used as support joints and transfer loads to a fixed support structure, which is an important accessory to the glass curtain wall.

- Q: Steel glass canopy glass is tiled or split jaws good

- Light steel glass canopy glass can also be used to strengthen the glass, including light weight, wind load, snow load and live load

- Q: 250 type curtain wall glass connection pawls how much punch

- Directly check the type of 250-type point curtain wall joints, see the size of the joints to know.

- Q: What is the use of borehole during the production of tempered glass?

- Drilling is the need for glass mounting - fixing the glass through the holes.

- Q: Used in the glass canopy on the distance between the claw claw how much, generally what is required in the canopy, I consult a few, the difference is a bit big, dizzy.

- Usually stay between 10mm glass glue joints, connections are two glass center hole spacing 220mm, from the heart to the glass edge of the hole is: (220-10) / 2 = 105mm

- Q: Curtain wall panel installation control points which

- The splicing jaws serve as an important accessory to the glass curtain wall, which plays an important role in the connection of the glass curtain wall. The mechanical properties are particularly important by passing the load to the steel structure or other body structure through the splice joint. Of the installation staff, in the point of the installation of the curtain wall accessories need to master more technical and knowledge points. Introduction is the stainless steel splicing jaws when you need to pay attention to the installation of some of the details, hoping to help everyone. The stainless steel splicing pawl-type curtain wall fittings are composed of splice joints, splicing claws, adapter parts and so on. The splicing jaws are mainly used as supporting link joints and pass the load to the fixed supporting structure system, which is connected with the glass curtain wall An important accessory. With the impact of the curtain wall industry, in order to achieve the best effect of the use of stainless steel splicing claws, construction details are essential, and today to introduce some of the details of the construction of the splicing claws and the need to pay attention to the problem. The first is the preparation before the installation.

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 2003 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Western Europe Northern Europe |

| Company Certifications | IS09001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Stainless Steel Glass Clamp of Building Hardware with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Pieces pc

- Supply Capability:

- 1200 Pieces Per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords