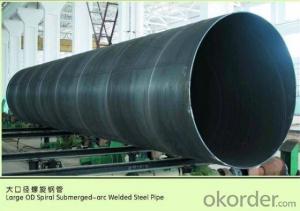

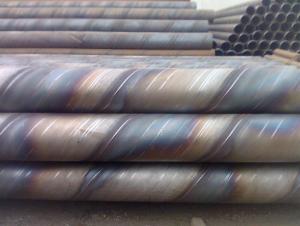

SPIRAL WELDED STEEL PIPE 24'' 26'' 28'' 30'' 32''CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Brand:TPCO

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: Seamed steel pipe seamless steel pipe, carbon steel pipe, galvanized pipe, four how to distinguish between

- Major use differentiation:1, seamed tube can withstand the maximum operating pressure is generally less than 20 kg, which is the most secure use. It is generally used in water, gas, compressed air and other low-pressure fluid;2 seamless tube can withstand ultra-high pressure, of course, its wall thickness will also increase, which needs to be designed according to pressure requirements. It is generally used in high-pressure oil pipes, boiler tubes and other high temperature and high pressure equipment. There are also seamless tubes for structural purposes, depending on the design requirements.3, there are some seamed steel pipe seamless treatment tube, it is the weld annealing treatment, eliminate the residual stress of the weld, the weld and base material, the pressure range of basic and seamless pipe is. May also consider the use of.4, of course, the market also has some use overall heating after drawing steel pipe joints or mandrel rolling seamless steel pipe, mainly in small size, only in the shape of this kind of pipe belongs to the seamless tube, it is not very good

- Q: Can steel pipes be used for oil drilling operations?

- Yes, steel pipes are commonly used for oil drilling operations. They possess the necessary strength and durability to withstand the harsh conditions of drilling and transporting oil. Additionally, steel pipes have excellent corrosion resistance, making them suitable for long-term use in the oil and gas industry.

- Q: Can steel pipes be used for underground gas distribution?

- Yes, steel pipes can be used for underground gas distribution. Steel pipes are commonly utilized in the gas industry due to their high strength, durability, and resistance to corrosion. They are capable of withstanding the pressure and stress associated with gas distribution systems. Additionally, steel pipes have been proven to be reliable and safe for transporting natural gas underground. However, it is essential to ensure that the steel pipes are properly coated and protected against corrosion to maintain their integrity and longevity. Regular inspections and maintenance are also necessary to identify and address any potential issues that may arise.

- Q: Are steel pipes suitable for nuclear power plants?

- Yes, steel pipes are suitable for nuclear power plants. Steel is a commonly used material in the construction of nuclear power plants due to its excellent mechanical properties, high strength, and durability. Steel pipes are used in various applications within these plants, including the transportation of cooling water, hot gases, and steam. The steel used in nuclear power plants is carefully selected and tested to meet stringent safety regulations and quality standards. It is crucial for these pipes to have excellent resistance to corrosion and high-temperature environments, as they are exposed to harsh conditions such as high pressure, high temperatures, and radioactive materials. Furthermore, steel pipes have a long service life and require minimal maintenance, making them a cost-effective choice for nuclear power plants. They can withstand extreme conditions, ensuring the safe and reliable operation of the plant. Additionally, steel pipes can be easily fabricated, installed, and repaired, which is essential for the efficient functioning of a nuclear power plant. Overall, steel pipes are highly suitable for nuclear power plants due to their strength, durability, resistance to corrosion, and ability to withstand extreme conditions.

- Q: How are steel pipes used in the manufacturing of food processing machinery and equipment?

- Steel pipes are an essential component in the manufacturing of food processing machinery and equipment due to their numerous advantageous properties. These pipes are widely used in the food industry for their durability, corrosion resistance, and ability to withstand high temperatures and pressures. One of the primary applications of steel pipes in food processing machinery is for the transportation of various fluids and gases. These pipes are used to carry water, steam, and other liquids, as well as air and gases, throughout the processing plant. Steel pipes provide a reliable and hygienic means of transferring these substances, ensuring that the quality and safety of the food products are maintained. Moreover, steel pipes are also utilized in the design and construction of food processing equipment such as mixers, blenders, conveyors, and canning machines. These machines often require the use of pipes to facilitate the movement of ingredients, processing fluids, and cleaning agents. Steel pipes are an ideal choice for these applications due to their high strength, which allows them to handle the heavy loads and pressures associated with food processing operations. Another crucial aspect of steel pipes in food processing machinery is their resistance to corrosion. Food processing involves the use of various acidic and alkaline substances, as well as hot water and steam, which can cause corrosion in other materials. Steel pipes, particularly those made from stainless steel, are highly resistant to corrosion, ensuring that the machinery remains in optimal condition and prolonging its lifespan. Furthermore, the smooth internal surface of steel pipes allows for efficient and hygienic cleaning, as it minimizes the accumulation of food particles and contaminants. This is of utmost importance in the food industry, where maintaining high levels of cleanliness is essential to prevent the growth of bacteria and ensure food safety. In summary, steel pipes play a crucial role in the manufacturing of food processing machinery and equipment. Their durability, corrosion resistance, ability to handle high temperatures and pressures, and hygienic characteristics make them an ideal choice for the transportation of fluids and gases, as well as for the construction of various food processing equipment.

- Q: What's the difference between stainless steel seamless tube and stainless steel welded pipe?

- Stainless steel welded pipe is also a hollow section of steel, but it is welded through the plate into the steel pipe, so there is a welded steel pipe welding gap.

- Q: Can steel pipes be used for electrical conduits?

- No, steel pipes are not typically used for electrical conduits as they are conductive and can pose a safety risk. Electrical conduits are usually made of non-conductive materials such as PVC or metal with insulating coatings.

- Q: How do you calculate the buoyancy of submerged steel pipes?

- To calculate the buoyancy of submerged steel pipes, you need to consider the principle of Archimedes' buoyancy. This principle states that the buoyant force acting on an object submerged in a fluid is equal to the weight of the fluid displaced by the object. To calculate the buoyant force, you need to determine the volume of the fluid displaced by the submerged steel pipe. The volume can be calculated by multiplying the cross-sectional area of the pipe by the length of the submerged portion. Next, you need to determine the density of the fluid in which the steel pipe is submerged. This can be obtained from the fluid's properties or by referring to known values. Once you have the volume and density of the fluid, you can determine the weight of the fluid displaced by the submerged pipe using the equation: weight = volume × density × acceleration due to gravity. Finally, the buoyant force can be calculated by multiplying the weight of the displaced fluid by the acceleration due to gravity. This will give you the upward force exerted on the submerged steel pipe by the fluid. It is important to note that in order to accurately calculate the buoyancy of submerged steel pipes, you should also consider any additional factors such as the weight of the pipe itself, any attached equipment or coatings, and the specific conditions of the fluid in which it is submerged.

- Q: Can steel pipes be coated for aesthetic purposes?

- Yes, steel pipes can be coated for aesthetic purposes. Coatings such as paint, powder coating, or galvanizing can be applied to steel pipes to enhance their visual appearance and protect them from corrosion. These coatings can provide a variety of colors and finishes to suit different aesthetic requirements.

- Q: What are the limitations of using steel pipes?

- Some limitations of using steel pipes include their susceptibility to corrosion and rust, which can affect their durability and lifespan. Steel pipes are also relatively heavy and can be challenging to transport and install compared to lighter materials. Additionally, steel pipes may require more extensive maintenance and repairs due to their vulnerability to cracks and leaks.

Send your message to us

SPIRAL WELDED STEEL PIPE 24'' 26'' 28'' 30'' 32''CARBON

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords