Raw Materials for Refractory:Specialised Refractory Castables for Burner Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Customised solutions for your kilns

2.repair service

3.furnace construction service

4.high mechanical strength

5.ISO9001

1)Refractories for insulation of furnaces and kilns

2)Refractories to meet high-temperature erosion / corrosion

3)Refractories to take high-temperature loads

4)Refractories for continuing improvement in production & performance

5)Refractories for cost-effective manufacturing solutions

Physical & Chemical Properties of Refractory LH-85B

Product Name | Specialized castable for coal burner tube | Corundum Andalusite Castable For Burner | |||

Product Code | LH-80P | LH-85P | LH-70P | ||

Density(kg/m3) | ≥2.75 | ≥2.75 | ≥2.60 | ||

Chemical Component (%) | AL2O3+SiC | ≥75 | ≥80 | ≥70 | |

Cold Crushing Strength(MPa) | 110°C*24h | ≥90 | ≥90 | ≥80 | |

1100°C*3h | ≥100 | ≥110 | ≥90 | ||

1350°C*3h | ≥100 | ≥120 | ≥85 | ||

Modulus of Rupture(MPa) | 110°C*24h | ≥9 | ≥10 | ≥7 | |

1100°C*3h | ≥11 | ≥12 | ≥7 | ||

1350°C*3h | ≥12 | ≥13 | ≥10 | ||

Linear Change Rate(%) | 1100°C*3h | ±0.3 | 0.25± | ± 0.3 | |

1350°C*3h | ± 0.4 | ±0.4 | ±0.4 | ||

Maximum Service Temperature(°C) | 1600 | 1650 | 1600 | ||

Construction Method | Pouring& Vibrating | ||||

Application Area | Coal burner tube and high-temperature parts | ||||

Construction Service & Regulations

1.Check the size, specification, layout, installation and quality of the metal anchorage and make expansion

processing of the anchors.

2.Erect the formworks (hardwood or steel) in advance.

3.Unpacking and pouring the castable

4.Mixing

5.Installation of the mixed castables & Large area constrction

6.Vibrating

7.Before the castable block get final set,it can not bear any pressure or vibration.

8.Curing & Stripping

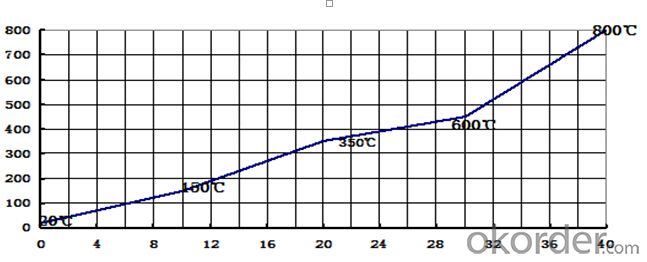

9.Baking the Furnaces (taking cement plant kiln as an example):

1). Keep the initial temperature at 20°C or so.

2). Please strictly follow the curve to conduct the baking work and increase the temperature smoothly and

evenly.

3). Lay out as many temperature measuring points as possible to monitor the temperature in the kiln, ensuring

the stable increase of the temperature.

FACTORY:

- Q: What requirements should refractory materials meet?

- Ladle is an necessary equipment to undertake molten steel and continuous casting. As many kinds of steel needs to be processed in the ladle, including argon blowing tempering, alloy composition fine-tuning, refining dusting and vacuum processing, working conditions of the ladle lining have worsened. Their working conditions are as follows. (1) The temperature of molten steel is higher than mold casting ladle. (2) the molten steel stays longerin the ladle. (3) ladle lining are subjected to volatilization and agitation of molten steel under high temperatures and in vacuum. (4) The impact on the lining when undertaking steel liner when the impact effect. Therefore requirements of the ladle refractories are as follows: (1) It can resist high temperature. Molten steel should be able to withstand high temperatures without melting. (2) It can resist thermal shock and can withstand molten steel without cracking and spalling. (3) It can resist slag erosion. The ladle should be able to withstand the erosion of lining caused by slag and alkalinity changes of slag. (4) it should have sufficiently high temperature mechanical strength to withstand the agitation and scouring of molten steel. (5) lined should have certain swelling property so that lining will be united as a whole under the effect of hyperthermal molten steel.

- Q: What are the models of refractory cables?

- There are bout four types. 1.NA-YJV / NB-YJV Crosslinked polyethylene insulated PVC sheath A (B) class fire-resistant power cable 2.NA-YJV22 / NB-YJV22 Crosslinked polyethylene insulated steel belt braiding PVC sheath A (B) class fire-resistant power cable 3.WDNA-YJY / WDNB-YJY Crosslinked polyethylene insulated polyolefin sheath A (B) class low smoke no halogen fire retardant power cable 4.WDNA-YJY23 / WDNB-YJY23 Crosslinked polyethylene insulated steel belt braiding polyolefin sheath A (B) class low smoke no halogen fire retardant power cable

- Q: How long can gypsum board endure fire?

- Fire endurance refers to the fire-resistent limit of the whole system of light-gauge steel structure coupled with gypsum. It does nor merely refers to gypsum board. Fire endurance of the common gypsum board with the thickness of 9.5mm keeps 1.5 hours. Those gypsum board with the thickness of 12mm has a fire endurance of 3 hours.

- Q: what is the requirements of roofing insulation materials fire rating?

- The fireproofing requirements of architectural design are regulated by architectural design fire?safety?rules, roofing insulation material only has the requirements of materials combustion performance, namely non-combustible material. No fire rating requirements.

- Q: How long is the duration of fire resistance that fireproof door of level B can endure?

- According to the duration of fire resistance, fireproof doors can be divided into three levels, namely level A,B,C. And accordingly, the duration of fire resistance of them should not lower than 1.20h, 0.90h and 0.60h. Fireproof door, a door that can meet the requirements of fire resistance stability, fireproof door integrity and thermal insulation at a certain time, is a fireproof separator which is located in fireproof partition, emergency staircase and vertical silo. Apart from functioning as a common door, a fireproof can also prevent the spread of fire and smoke in a certain period to make sure that people are safely evacuated.

- Q: who knows how to classify the fire resistant levels of fireproofing material?

- Materials used in construction are called construction materials. The combustion performance of construction materials refers to all physic and chemical changes happened when burning or contacting fire, the properity is measured by combustibility of material surface and flame transmission, heating, smoke,charring, weightlessness, and the producing of toxicity resultant. Our national standard GB8624-97 classifies the combustion performance of construction materials into following several levels. Class A: Incombustible building material, class B1: Nonflammable building material, class B2: Combustible?building?materials, class B3: Inflammability construction materials, generally speaking: first fire resistant level construction is the mixed construction of reinforced concrete structure or brick wall and steel concrete structure; second fire resistant level construction is the steel structure roof truss, reinforced concrete column or mixed structure made by brick wall; third fire resistant level construction is the wood and brick made by wooden roof and brick wall; fourth fire resistant level one is the combustible?structure made by wooden roof, hard-comnustible component wall.

- Q: What are Grade-A waterproof inorganic thermal insulation materials?

- There is a market confusion in Grade-A waterproof inorganic thermal insulation materials. The products mainly include Grade-A monomer material like roc wool and ultra-thin insulation board and Grade-A composite material. Many Grade-B materials wraaped with calcium silicate board or foam cement belongs to Grade-A material, such as phenolic aldehyde composite. Some foamed materials with filling also belongs to Grade-A material. However, there are few products with Grade-A qualification. Many manufacturers are working on the margins of the records with Grade-A fireproofing performance examining report. But this situation will not be too long.

- Q: What is shapeless refractory with high performance?

- The popular ones are: Non-cement fine powder bonded castable is a functional refractory castable with nano material introduced.

- Q: What are the fireproofing materials of the external wall included?

- According to the external wall thermal insulation materials, the external insulation materials is in general divided into Class A and Class B. The A class is non-combustible material. The B class is combustible materials. The fire disasters of the CCTV building and Shenyang hotel are both caused by the B level materials. Generally, the A level material will be used, and some prices are even cheaper than the B-grade material. A level is roughly divided into thermal?mortar, phenolic foam Board, rock wool board, foam cement board, and so on. I hope my answer will help you!

Send your message to us

Raw Materials for Refractory:Specialised Refractory Castables for Burner Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords