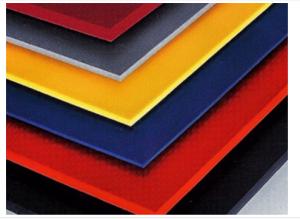

SMC Sheet - 1.0mm Thickness Strong Fire Resistance / All Kinds of Colors / FRP Sheet for Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

SMC is the short form of sheet mounding compound. This is a raw material for mold pressing. The core is chopped strand and unsaturated polyester resins paste that are covered by LDPE & HDPE sheet. It is 3mm-6mm thick , 600mm-1200mm wide and packing in rolls or boxes. When using , be sure to cut , weigh , uncover film, and join in the heat up mould, after adding high pressure and preserve a time, then you can take off membrane to get the product.

Feature

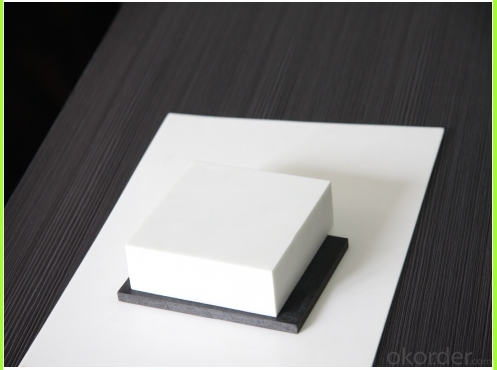

Higher mechanical strength

Excellent leak-proof electrical

Excellent thermal stability, chemical corrosion resistance

Low water absorption, good dimensional stability, war page small

Reliable arc resistance and voltage withstand, high dielectric strength

Specification

Product name | Fiberglass Reinforced Polyester Corrugated Sheet |

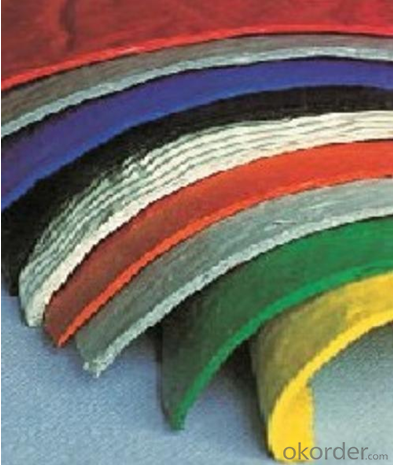

Material | High-performance protective film, unsaturated polyester resin, fiberglass |

Layer | 1 layer |

Width | 900mm,930mm,1100mm |

Thickness | 0.8mm,1.0mm,1.2mm,1.5mm,2.0mm,3.0mm |

Length | 5800mm,11800mm or customized according to requirement of customers |

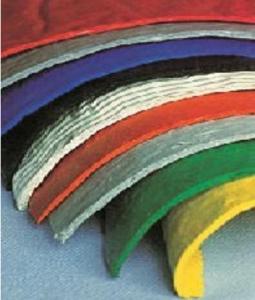

Color: | Clear, Red, Yellow, Green and opal |

Guarantee: | 10 years |

Certification: | ISO9001 SGS ROSH |

Delivery time | 5-7days(general) depend on the style and quantity |

detail features | 1.The light transmission It is between 60-85%. Light through FRP lighting sheet scatters and is mild. It will not form a light band so as to make the indoor brighter. |

Advantage

Beautiful appearance, long service life

Absolute seal waterproof performance, corrosion resistance

Solution of wood steel plastic meter box easy to aging, easy corrosion, poor insulation, poor cold resistance, poor flame retardant, the short life of the shortcomings

Application

1. Application in automobile industry

(1) Suspension parts, front and rear bumpers, instrument panels and the like

(2) Car body and body parts, body shell, hard shell roof, floors, car doors, cooling air grille panels, fore plate, spoiler, luggage hatch cover, sun shade, SMC fender, engine bonnet, headlight reflector

(3) The engine cover under parts such as air conditioner shell: wind shield, the intake manifold cover, Fan vanes ring, heater cover, tank parts, brake system components, and the Battery bracket, engine noise barriers and so on

2. Application in electric industry and communication engineering

(1) Electrical housings: electrical switch box, SMC electrical wiring boxes, dashboard cover, etc

(2) Electric elements and electrical parts: SMC insulator, insulated tools, motor cover, etc

3. Application in rail vehicle

SMC railway vehicles, window frames, bathroom components, seat, coffee table tops, SMC compartment wall and SMC roof

4. Application of in the bathroom

5. Application in ground

6. Application in the explosion-proof electrical equipment shell

7. Applications in wireless communications

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

FACTORY

PACAKGE

- Q: Where are the differences between the products made of stone and resin?

- Various patterns of natural stone including granite, marble, more commonly used are black and white two.Advantages: natural stone density is relatively large, hard texture, anti scratch performance is outstanding, good wear resistance, and the texture is very beautiful, the cost is relatively low, the most commonly used types of price of only a few hundred yuan a meter, which belongs to a material economy. High grade natural stone table price, there are thousands of dollars.Disadvantages: 1. natural stone pores, easy to accumulate grease; 2. natural stone is short, not two splicing gap when all blend into one harmonious whole easy to breed bacteria; 3., the density of natural stone, need a strong cabinet support; although hard, but the lack of flexibility, in case of a will crack, it is difficult to repair, some see the natural crack is not seen, rapid temperature changes also occur in case rupture; natural marble brittleness, not more than 1 meters of the format table.And resin products on the market are more common, product quality varies greatly. High quality resin material is made of high quality resin, aluminum hydroxide, natural ore particles, natural pigments, pearl powder, curing and mixing. The material is made of high quality resin 33%. Aluminium hydroxide and granules 65%. Other materials account for about 2% (depending on the color). Its characteristics can meet the needs of various family decoration. It has the characteristics of stable quality, high quality, environmental protection and cheap quality. It does not add any low grade industrial resin and calcium carbonate powder. This product is durable, durable and new, and is the preferred product for general customers. The price is about 400 meters. More expensive than natural stone

- Q: Which is good for SMC composites and honeycomb composites?

- 3D printing can now print cellular structures directly.

- Q: Does floor heating emit toxic gas?

- Good quality tiles, smooth surface, uniform surface, smooth, bright, consistent color and heavier weight

- Q: What are the raw materials for composite manhole covers?

- The composite manhole cover adopts high temperature and high pressure molding technology with high degree of polymerization, large density, good impact resistance and tensile strength, and has the advantages of wear resistance, corrosion resistance, no rust, no pollution, no maintenance, etc.. General composite manhole covers are also BMC composite cover and SMC composite manhole cover. SMC polymer composite manhole cover, Beijing Pan Asia Telecom's reliable, but also applied for the color of the patent

- Q: What is polymer composite cable trench cover plate?

- From the point of view of cost performance, the general FRP grille grille cover is more economical and durable.This answer is recommended by the questioner

- Q: Why outdoor SMC table tennis table longer service life?

- SMC material is made up of fiber sheet material and is molded by high temperature. The water absorption rate is 0. SMC table tennis table chemical resistance performance is strong, anti climate strong, reasonable structure, enhance the stability in the premise of not reducing the performance of the products, and not easy to deform, paint film is more uniform, enhanced adhesion; surface crack. SMC table tennis table by forming a 1000T high temperature molding press, the table produced by the procedures of fine processing, table design and construction mechanics combined in surface stress with field type reinforcement reinforcement, and the material adding alkali silane reinforcing fibers.

- Q: Why is unsaturated polyester resin used in sheet molding? Why don't short fiber moulding plastics use unsaturated polyester resins?

- BMC SMC produced a good sheet or mass, there is a mature thickening process, the temperature should be placed for more than a dozen hours or more time to mature thickening.

- Q: Is the SMC material poisonous?

- SMC material is non-toxic, environmentally friendly, in line with the RoHS standard, you can rest assured that the use and take.

- Q: How do you measure the excess of the compound in the house?

- SMC uses roving SMC, a sheet molding compound, for automotive parts, bathtubs, water tanks, purifying tanks, seats, etc..

- Q: Where is the difference between glass fiber reinforced plastic cable tray and SMC cable trough?

- SMC bridge, molding process, mass or sheet, high price. Use in high-speed rail, subway and other demanding occasions.

Send your message to us

SMC Sheet - 1.0mm Thickness Strong Fire Resistance / All Kinds of Colors / FRP Sheet for Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords