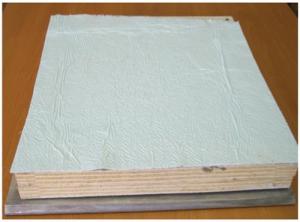

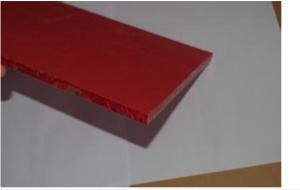

SMC Sheet - Red

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Kg m.t.

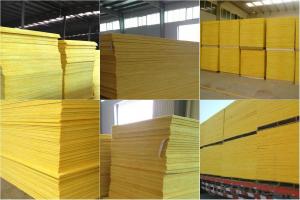

- Supply Capability:

- 1000Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

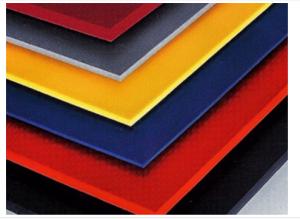

specification of SMC SHEET-RED

Color: red

Thickness: 4.0mm

Spot goods size(width and length): 1500mm×1500mm

Professional production & Processing services of SMC SHEET-RED

(1) According to customer demand,production and processing of various machinery and electrical electric equipment parts

(2) Undertake the works of reaction tank,plating tank,purifying-tank,electrolyzer and the like

Product processing solutions of SMC SHEET-RED

Sawing,drilling,milling,turning,routing,carving,die-cutting,shearing with different tools or machines

Characteristics of SMC SHEET-RED

1.Base attribute

(1) Higher strength

(2) Excellent leak-proof electrical

(3) Excellent thermal stability,chemical corrosion resistance

(4) Low water absorption,good dimensional stability, warpage small

(5) Reliable arc resistance and voltage withstand,high dielectric strength

2.Advantages

(1) Solution of wood steel plastic meter box easy to aging,easy corrosion,poor insulation,poor cold resistance,poor flame retardant,the short life of the shortcomings

(2) Absolute seal waterproof performance,corrosion resistance

(3) Beautiful appearance,long service life

Application of SMC SHEET-RED

1.Application in automobile industry

(1) Suspension parts,front and rear bumpers,instrument panels and the like

(2) Car body and body parts,body shell,hard shell roof,floors,car doors,cooling air grille panels,fore plate,spoiler,luggage hatch cover,sun shade,SMC fender, engine bonnet,headlight reflector

(3) The engine cover under parts such as air conditioner shell:wind shield,the intake manifold cover,Fan vanes ring,heater cover,tank parts,brake system components,and the Battery bracket,engine noise barriers and so on

2.Application in electric industry and communication engineering

(1) Electrical housings:electrical switch box,SMC electrical wiring boxes,dashboard cover,etc

(2) Electric elements and electrical parts:SMC insulator,insulated tools,motor cover,etc

3.Application in rail vehicles

SMC railway vehicles,window frames,bathroom components,seat,coffee table tops,SMC compartment wall and SMC roof

4.Application in architectural engineering

Water tank,bathes the thing,purifies the trough,building templates,storage component

5.Application in the explosion-proof electrical equipment shell

6.Applications in wireless communications

7.Application of in the bathroom

8.Application in ground

- Q: What material is the resin composite manhole cover made of?

- Glass fiber yarn, filler, resin, curing agent, accelerator, mold, etc.

- Q: Where are the differences between the products made of stone and resin?

- If the quality of the tree ester products, the release of toxic substances will be more, longer.Of course, the stone now has man-made, with resin produced all kinds of marble and sheet metal.

- Q: What's the difference between a ductile iron well and a composite resin manhole cover?

- Composite manhole cover has the advantages of low cost, light weight, anti theft, the advantages of reducing the noise in city; corrosion protection, high performance composite resin covers SMC sheet products, acid, alkali and salt corrosion, rust and so on 50 or 150 DEG C for use in harsh conditions.

- Q: The difference between glass fiber reinforced plastic antenna and cannon antenna

- SMC and its molded products have the following characteristics: light weight, high strength, precise size, good batch quality and zero shrinkage. With a surface level, mechanization, a high degree of automation, applicable to high surface quality requirements, large output, uniform thickness of the product.

- Q: Which is good for SMC composites and honeycomb composites?

- 3D printing can now print cellular structures directly.

- Q: Does floor heating emit toxic gas?

- One check: check the product radioactive test report, see if the radioactive material is over standardTwo test: Please professionals with instruments for radioactive detection, to see whether and product radioactive test report in line with

- Q: Why is unsaturated polyester resin used in sheet molding? Why don't short fiber moulding plastics use unsaturated polyester resins?

- BMC SMC produced a good sheet or mass, there is a mature thickening process, the temperature should be placed for more than a dozen hours or more time to mature thickening.

- Q: What is a sheet of material? Is it plastic? What is it used for?

- Glue is plastic, the processing process is the raw material in the machine, through the melting of high temperature into the mold or squeeze, blister molding.

- Q: What is the difference between a gain fiberglass and an ordinary omnidirectional antenna?

- SMC, which is composed of SMC, unsaturated polyester resin, glass fiber roving, and other materials with special equipment by SMC forming unit made of sheet, and then by thickening, cut, put on metal mold by high pressure and high temperature curing made.

- Q: SMC sheet pressing out the product is not bright, what is the reason?

- Different grades of tree ester use different raw materials, new glycol, propylene glycol content of higher tree ester, made out of sheet pressure product brightness is better, but the higher the cost.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 200,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

SMC Sheet - Red

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Kg m.t.

- Supply Capability:

- 1000Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords