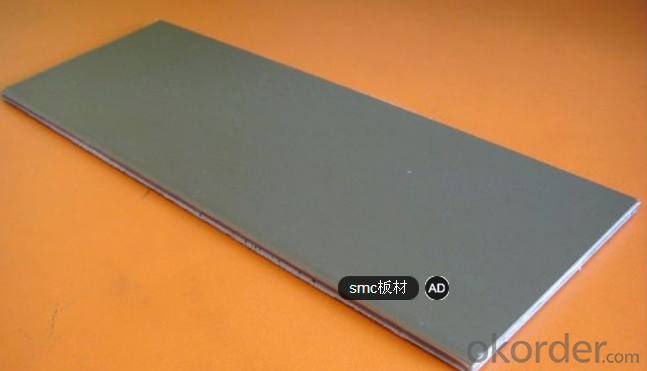

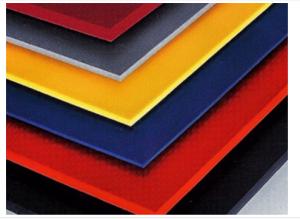

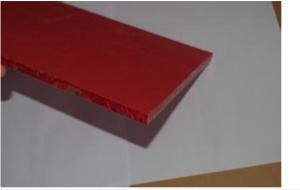

SMC Sheet - 1.0mm Thickness Strong Fire Resistance Colorful SMC FRP Sheet with Best Price/High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

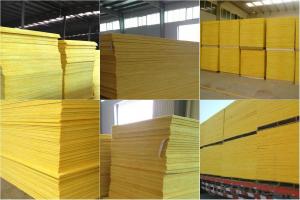

Introduction

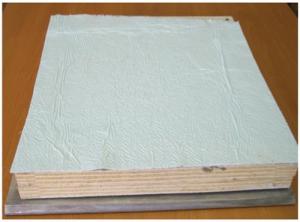

SMC is the short form of sheet mounding compound. This is a raw material for mold pressing. The core is chopped strand and unsaturated polyester resins paste that are covered by LDPE & HDPE sheet. It is 3mm-6mm thick , 600mm-1200mm wide and packing in rolls or boxes. When using , be sure to cut , weigh , uncover film, and join in the heat up mould, after adding high pressure and preserve a time, then you can take off membrane to get the product.

Feature

l Higher mechanical strength

l Excellent leak-proof electrical

l Excellent thermal stability, chemical corrosion resistance

l Low water absorption, good dimensional stability, war page small

l Reliable arc resistance and voltage withstand, high dielectric strength

Specification

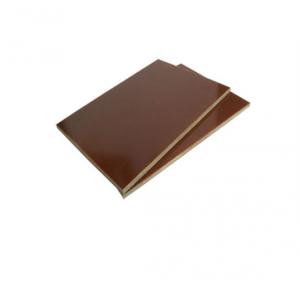

Product name | Fiberglass Reinforced Polyester Corrugated Sheet |

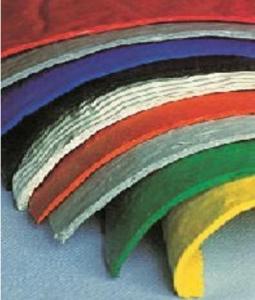

Material | High-performance protective film, unsaturated polyester resin, fiberglass |

Layer | 1 layer |

Width | 900mm,930mm,1100mm |

Thickness | 0.8mm,1.0mm,1.2mm,1.5mm,2.0mm,3.0mm |

Length | 5800mm,11800mm or customized according to requirement of customers |

Color: | Clear, Red, Yellow, Green and opal |

Guarantee: | 10 years |

Certification: | ISO9001 SGS ROSH |

Delivery time | 5-7days(general) depend on the style and quantity |

detail features | 1.The light transmission It is between 60-85%. Light through FRP lighting sheet scatters and is mild. It will not form a light band so as to make the indoor brighter. |

Advantage

l Absolute seal waterproof performance, corrosion resistance

l Beautiful appearance, long service life

Application

1. Application in automobile industry

(1) Suspension parts, front and rear bumpers, instrument panels and the like

(2) Car body and body parts, body shell, hard shell roof, floors, car doors, cooling air grille panels, fore plate, spoiler, luggage hatch cover, sun shade, SMC fender, engine bonnet, headlight reflector

2. Application in electric industry and communication engineering

(1) Electrical housings: electrical switch box, SMC electrical wiring boxes, dashboard cover, etc

(2) Electric elements and electrical parts: SMC insulator, insulated tools, motor cover, etc

3. Application in rail vehicle

SMC railway vehicles, window frames, bathroom components, seat, coffee table tops, SMC compartment wall and SMC roof

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

FACTORY

PACAKGE

- Q: What composite material is used for composite manhole covers?

- The composite well covers adopts unsaturated polyester resin as matrix and fiber reinforced thermosetting composite material, also called group molding plastics (DMC). It is made of pressing molding technology, and it is a new type of environmental protection type electric power cover plate.

- Q: Which is good for SMC composites and honeycomb composites?

- The method of forming a honeycomb structure of a composite material suppresses the sheet material into a corrugated form and then welds or sticks together to form a honeycomb structure;

- Q: What are the raw materials for composite manhole covers?

- Fiber reinforced thermosetting composite material based on unsaturated polyester resin, also called group molding plastics (DMC), is made by pressing forming technology. It is a new type of environmental friendly power panel.

- Q: What is polymer composite cable trench cover plate?

- From the point of view of cost performance, the general FRP grille grille cover is more economical and durable.This answer is recommended by the questioner

- Q: Seeking better SMC manufacturers in the industry, it is best to write more, thank you!

- Hongkong and Shanghai can be imported directly. The average delivery time is about 20-30 days. If you inform the goods in advance, 10%-20% deposit can be prepared in advance. Every word is my own play, I hope the landlord how much help.

- Q: Why is unsaturated polyester resin used in sheet molding? Why don't short fiber moulding plastics use unsaturated polyester resins?

- BMC SMC produced a good sheet or mass, there is a mature thickening process, the temperature should be placed for more than a dozen hours or more time to mature thickening.

- Q: Is the SMC material poisonous?

- This material is very good, non-toxic, give you a link, you refer to, remember to give a adoption Oh!

- Q: Thickening mechanism of Magnesium Oxide by SMC

- Magnesium Oxide also needs to adjust its activity as the climate changes. If the activity is relatively high, then it will cause glass fiber reinforced thickening faster;

- Q: How is glass fiber reinforced plastic water tank made?

- FRP hand lay up tank: made of resin glass cloth paste hand processing tank frame surface

- Q: Are SMC tablets harmful to the body? Our factory produces SMC. I have contact every day. Is there any odor that is harmful to my health?

- Don't worry, because this material is generally used in aviation, aerospace, aircraft, high-speed rail, and so on

Send your message to us

SMC Sheet - 1.0mm Thickness Strong Fire Resistance Colorful SMC FRP Sheet with Best Price/High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches