SMC Sheet Excellent Thermal Resistance Rock Wool Blanket with Wire Mesh Water Repellent, Asbestos Free

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

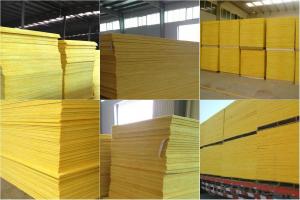

CNBM rock wool blanket with wire mesh Overview:

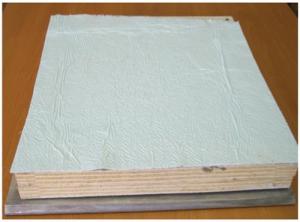

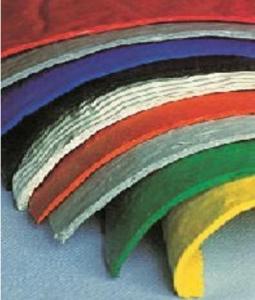

CNBM rock wool blanket with wire mesh is a robust insulation product stitched on one side with galvanized or stainless steel wire mesh and comes in various thickness and density.

CNBM rock wool blanket with wire mesh Product Specifications¼

Density(kg/m3) | Width(mm) | Thickness(mm) | Length(m) | Facing |

60-150 | 600 | 30-200 | 2.5 , 3 , 5 | wire mesh |

We can make special production according to your requirement.

Rock Wool Blanket With Wire Mesh Technical Parameters:

Item | Unit | Index | Standard |

Density | Kg/m3 | 60-200kg/m3 | GB5480.3 |

Average value of fiber | um | 4-7 | GB5480.4 |

Slag ball content (granule diameter) | % | 6 | GB5480.5 |

Volume water absorption | % | 2 | GB/GB16401-1996 |

Heat absorption | % | 1 | GB5480.7 |

Moisture resistivity | % | 98 | B10299-88 |

- Q: Is the gas released from the heating of the SMC sheet poisonous?

- SMC sheet is made of unsaturated polyester resin, glass fiber and aluminium hydroxide powder by certain process

- Q: What is the difference between plastic die casting and compression molding? Please be specific

- Equipment: simple, but also the main features of plastic equipment. The two halves of the platen are joined together to heat and pressurize the material into a predetermined shape. Most pressing processes are hydraulically operated; pneumatic operations are also used. On the two plate moves in the 4 corner posts up and down under pressure. According to the size of press and mould equipment, the pressure is usually 20 - 1000 tons. The size of the platen is usually 8 inches, 2 to 5 feet, 2.There are different degrees of automation in the mold release after charging and curing. The most modern hydraulic press is often used. Previous simple systems include temperature control, pressure control, stop pressure control, and time control. Modern equipment is controlled by more advanced microprocessors. For thinner products, a heating cylinder or belt heater can be used in the plate. For deeper parts, use a cylindrical electric heater, steam heating or hot oil heating system. There are several kinds of pressure heating system used in plastic with uniform temperature steam heating mode, but the heating temperature limit below 350 DEG F; barrel heating or other heating (heating coil, heating etc.) is relatively clean, easy to maintain, with more universal; oil heating, because the heating medium circulation is stable, so the uniform heating. Now there are many new heating methods, hot water heating, similar to hot oil heating, heating medium, one water, one gas combustion, continuous cycle, can provide higher plastic temperature.

- Q: Does floor heating emit toxic gas?

- After the purchase contract signed with the merchant, asking for invoices, in order to avoid problems when businesses shirk responsibility

- Q: What are the raw materials for composite manhole covers?

- Because the SMC polymer resin composite covers are made of resin and SMC polymer sheet pressing, without reinforcement than usual covers light weight 2/3, but this kind of SMC polymer resin composite covers and not because of its weight and reduce its carrying capacity, SMC polymer resin composite well cover bearing is three times that of ordinary resin composite manhole cover bearing, up to 90 tons

- Q: What is polymer composite cable trench cover plate?

- From the point of view of cost performance, the general FRP grille grille cover is more economical and durable.This answer is recommended by the questioner

- Q: Seeking better SMC manufacturers in the industry, it is best to write more, thank you!

- I don't quite understand your question. SMC has only one manufacturer. I'm the agent of SMC. You don't know much about it

- Q: Why is unsaturated polyester resin used in sheet molding? Why don't short fiber moulding plastics use unsaturated polyester resins?

- BMC SMC produced a good sheet or mass, there is a mature thickening process, the temperature should be placed for more than a dozen hours or more time to mature thickening.

- Q: What is the difference between a gain fiberglass and an ordinary omnidirectional antenna?

- SMC and its molded products as a new glass fibre reinforced plastics, glass steel, the processing methods can be divided into: hand molding, injection molding, paste pultrusion, winding molding, resin transfer molding, molding and other kinds of processing methods.

- Q: What is the use of resin fiber powder extracted from the circuit board without breaking the law?

- Generally do not understand, go to Baidu Encyclopedia (don't waste your points) with molten glass made of very fine fiber, insulation, heat resistance, good corrosion resistance, high mechanical strength. Used as insulating material and as raw material for glass fiber reinforced plastics.

- Q: SMC sheet pressing out the product is not bright, what is the reason?

- This is mainly related to unsaturated polyester resins, and tree esters are classified into many grades

Send your message to us

SMC Sheet Excellent Thermal Resistance Rock Wool Blanket with Wire Mesh Water Repellent, Asbestos Free

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords