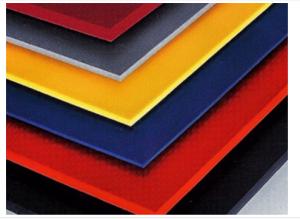

SMC Sheet - 1.0mm Thickness Strong Fire Resistance Colorful SMC FRP Sheet with Best Price/High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

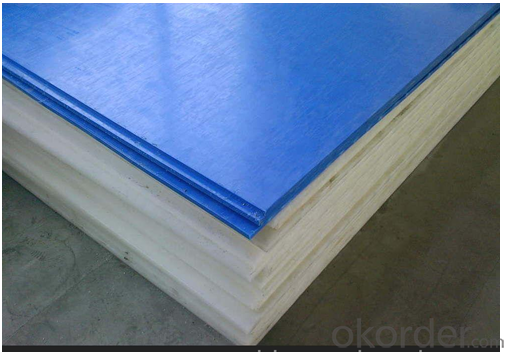

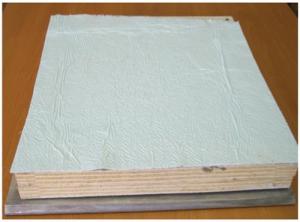

SMC is the short form of sheet mounding compound. This is a raw material for mold pressing. The core is chopped strand and unsaturated polyester resins paste that are covered by LDPE & HDPE sheet. It is 3mm-6mm thick , 600mm-1200mm wide and packing in rolls or boxes. When using , be sure to cut , weigh , uncover film, and join in the heat up mould, after adding high pressure and preserve a time, then you can take off membrane to get the product.

Feature

l Higher mechanical strength

l Excellent leak-proof electrical

l Reliable arc resistance and voltage withstand, high dielectric strength

Specification

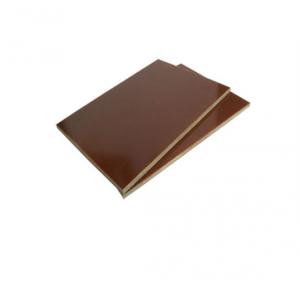

Product name | Fiberglass Reinforced Polyester Corrugated Sheet |

Material | High-performance protective film, unsaturated polyester resin, fiberglass |

Layer | 1 layer |

Width | 900mm,930mm,1100mm |

Thickness | 0.8mm,1.0mm,1.2mm,1.5mm,2.0mm,3.0mm |

Length | 5800mm,11800mm or customized according to requirement of customers |

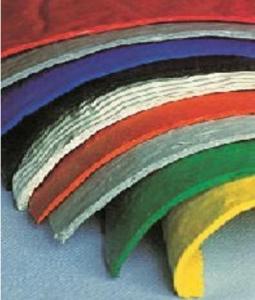

Color: | Clear, Red, Yellow, Green and opal |

Guarantee: | 10 years |

Certification: | ISO9001 SGS ROSH |

Delivery time | 5-7days(general) depend on the style and quantity |

detail features | 1.The light transmission It is between 60-85%. Light through FRP lighting sheet scatters and is mild. It will not form a light band so as to make the indoor brighter. |

Advantage

l Solution of wood steel plastic meter box easy to aging, easy corrosion, poor insulation, poor cold resistance, poor flame retardant, the short life of the shortcomings

l Absolute seal waterproof performance, corrosion resistance

l Beautiful appearance, long service life

Application

1. Application in automobile industry

(1) Suspension parts, front and rear bumpers, instrument panels and the like

(2) Car body and body parts, body shell, hard shell roof, floors, car doors, cooling air grille panels, fore plate, spoiler, luggage hatch cover, sun shade, SMC fender, engine bonnet, headlight reflector

2. Application in electric industry and communication engineering

(1) Electrical housings: electrical switch box, SMC electrical wiring boxes, dashboard cover, etc

(2) Electric elements and electrical parts: SMC insulator, insulated tools, motor cover, etc

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

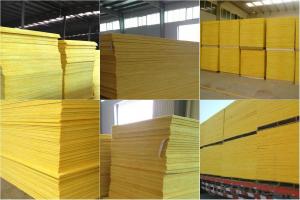

FACTORY

PACAKGE

- Q: Is the quality of the resin wall the same?

- Of course there are differences, and there are several kinds of resin background walls.

- Q: Which is good for SMC composites and honeycomb composites?

- The method of forming a honeycomb structure of a composite material suppresses the sheet material into a corrugated form and then welds or sticks together to form a honeycomb structure;

- Q: What are the raw materials for composite manhole covers?

- Because the SMC polymer resin composite covers are made of resin and SMC polymer sheet pressing, without reinforcement than usual covers light weight 2/3, but this kind of SMC polymer resin composite covers and not because of its weight and reduce its carrying capacity, SMC polymer resin composite well cover bearing is three times that of ordinary resin composite manhole cover bearing, up to 90 tons

- Q: Who knows what is the process flow of FRP splicing water tank?

- After 48h heating after curing, inspection sheet, in accordance with the specifications required for Hengxin water tank for cutting, weighing, stacked, evenly placed has cleaning and mold heating to 120-140 DEG C, and after a period of time after the opening.

- Q: In recent years, what new materials have come into use in the automotive interior, or in the future?

- At present, LFT has become a new lightweight material for automobile which can challenge aluminum alloy and fiber reinforced thermosetting composites, and has a strong market competitiveness. According to reports, in recent years, the use of LFT made automotive products market share increased by about 15%, and maintain a strong upward trend, this phenomenon has aroused great concern among professionals in the industry.

- Q: What is a sheet of material? Is it plastic? What is it used for?

- Yes, plastic, sheet material, a variety of raw materials can be done, sheet is extrusion, the use of a wide range of specific to see in what areas?

- Q: Is the SMC material poisonous?

- SMC material is non-toxic, environmentally friendly, in line with the RoHS standard, you can rest assured that the use and take.

- Q: What is the difference between a gain fiberglass and an ordinary omnidirectional antenna?

- SMC and its molded products have the following characteristics: light weight, high strength, precise size, good batch quality and zero shrinkage. With a surface level, mechanization, a high degree of automation, applicable to high surface quality requirements, large output, uniform thickness of the product.

- Q: What is the use of resin fiber powder extracted from the circuit board without breaking the law?

- (1) high tensile strength and small elongation (3%).(2) high elasticity and good rigidity.(3) the elongation within the elastic limit is large and the tensile strength is high, so the impact energy is large.(4) for inorganic fiber, with non flammable, chemical resistance.(5) water absorption is small.(6) the scale stability and heat resistance are excellent.(7) good processability, can be used as stock, bundle, felt, weaving and other forms of products.(8) transparent and permeable to light(9) the development of surface treatment agents with good resin properties.(10) the price is cheap.

- Q: Composite manhole cover or cast iron well cover?

- The new composite made of color composite manhole covers can reach 90 tons, which can be used as a substitute for cast iron covers, and the northern color is the patent name of Beijing Pan Asia Electric

Send your message to us

SMC Sheet - 1.0mm Thickness Strong Fire Resistance Colorful SMC FRP Sheet with Best Price/High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches