Small induction furnace for gold/silver melting

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | plywood case packing with export standard |

| Delivery Detail: | one month after receiving deposit |

Specifications

1. Excellent performance,

2. High efficiency,

3. Energy-saving,

4 .Flaxible n easy operation,

5. Environment-friendly

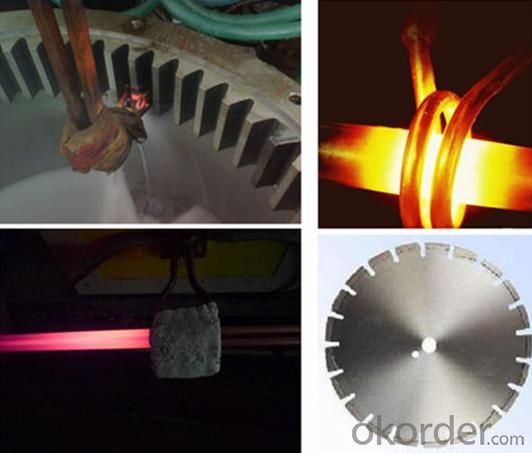

The small Medium Frequency induction gold/silver melting Furnace has below characteristics:

1.fast smelting with low production cost,low pollution and environment-friendly

2.used for melting stainless steel,alloy steel,iron,aluminium,copper

3.power adjustment flexibility.Be able to continuously smooth adjustment.Temperature uniformity can be easily controlled.

4.Induction Coil should be fired of Anaerobic Rectangle thick-walled Red Copper, thickness of Tube Wall should be uniform, and Hydroelectric Connectors should be durable and easily disassemble. There are water-cooled coils at the upper part and lower part of Induction coil to make the lining material being heated uniform and even axially as well as to extend service age for the furnace liner. To strengthen the insulation effect of induction coil, the surface of induction coil should be painted with high-strength insulation resin, and at inside, outside and interims of the induction coil should be applied with Refractory Daub(refractoriness (1800 C).

5.The Refractory Daub is with excellent insulation and heat shielding performance, which will protect the induction coil from being damage if the furnace liner is broken. With plenty of experience accumulated from designing adjusting, certain quantity of experimental data about Height-Diameter Ratio (H/D Ratio) is built up. We applied different H/D Ratio for inductors with different capacity; this Computer Optimal Designed H/D Ratio greatly improved the efficiency of inductor.

6. high responsibility of field installation (provide material for installation), debugging, training and all other essential supporting.

Super quality of Steel-cased small Medium Frequency induction gold/silver melting Furnace with reasonable price are available all the time by CNBM, and we warmly welecome customers from all over the world visit us.

| rated capacity(T) | rated power(KW) | rated frequency(HZ) | transformer capacity(KVA) | secondary voltage(v) | inductor voltage(V) | melting rate(T/hour) | power consumption(KWH/T) |

| 40T | 25000 | 150 | 4*6300 | 8×6φ1500V | 4000 | 38 | 480 |

| 30T | 20000 | 200 | 3*6300 | 8×6φ1500V | 4000 | 29 | 500 |

| 20T | 11000 | 250 | 2*6300 | 2*6φ1250V | 3600 | 20 | 500 |

| 15T | 10000 | 300 | 2*5500 | 2*6φ1250V | 3600 | 15 | 500 |

| 10T | 6000 | 400 | 1*8000 | 6φ1250V | 3600 | 10 | 550 |

| 8T | 5000 | 400 | 1*6300 | 6φ1250V | 3600 | 8 | 550 |

| 5T | 2500 | 500 | 1*3150 | 6φ1250V | 3600 | 5 | 550 |

| 3T | 2200 | 500 | 1*2500 | 6φ950v | 3200 | 3.8 | 580 |

| 2T | 1500 | 700 | 1*1600 | 6 φ800V | 2600 | 2.3 | 600 |

| 1.5T | 800 | 700 | 1*1000 | 6φ660V | 2800 | 1.7 | 600 |

| 1T | 700 | 1000 | 1*800 | 6φ750V | 1600 | 1.3 | 600 |

| 0.75T | 400 | 1000 | 1*400 | 3φ380V | 1600 | 0.8 | 630 |

| 0.5T | 300 | 1000 | 1*315 | 3 φ380V | 1600 | 0.6 | 750 |

| 0.35T | 250 | 1000 | 1*250 | 3 φ380V | 750 | 0.4 | 750 |

| 0.25T | 200 | 1000 | 1*200 | 3 φ380V | 750 | 0.28 | 750 |

| 0.15T | 160 | 1000 | 1*100 | 3 φ380V | 750 | 0.18 | 750 |

1.melting time and power consumption is important to equipment power,raw material shape and weight,operaor's skill level and other elements.

2.power parameters shall be subject to steel melting;lower power is required by melting of copper,aluminum,zinc,or other material with low melting point

3.scope supply equiment :an intermediate/medium frequency power supply cabinet,a capacitor box,an overturn control cabinet,two furnace bodies,two sets of reduction boxes and two water-cooling cables.

- Q: Selection of heat preservation material for industrial furnace

- Ceramic fiber blanket can be used.Ceramic fiber blanket color white, regular size, set fire, heat insulation, insulation in one. Free from any binding agent.

- Q: Should the industrial furnace shell cool down?

- Normally, the furnace shell temperature of an industrial furnace is below 50 degrees, so there is no need to cool down.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The main equipments of heat treatment are classified into two major categories: main equipment and auxiliary equipment. The main equipment includes heat treatment furnace, heating device, surface modification, surface oxidation device, surface mechanical enhancement device, cooling equipment, cold processing equipment, process parameter detection and control instrument; auxiliary equipment includes cleaning cleaning equipment, furnace atmosphere heating medium permeability meter preparation equipment, cooling device, quenching medium heavy transport machinery, quality testing equipment, power transmission line and auxiliary equipment, fire safety equipment, dust and other production fixture.

- Q: What are the combustion equipments used in industrial boilers?

- The boiler is an energy conversion equipment. The energy input to the boiler has the chemical energy and the electric energy in the fuel. The boiler outputs steam with certain heat energy and high temperature water.

- Q: What's the role of anchor bricks in industrial furnaces?

- Anchorage brick is a new type of anchor brick relates to an industrial furnace, in particular to anchor brick of an industrial furnace roof, including column hanging end and the anchor structure, opened in the anchor on the surface of the spacing of the grooves in the anchor on at least one surface is arranged along the length direction ribs is provided with ribs, the ribs of the reinforcement and anchorage tension, tensile and flexural strength was obviously improved, the stress generated in the groove at the bar at the barrier can not continue to transfer, so the anchor brick of this kind of structure is not easy to break.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: How many kinds of industrial electric furnaces are there?

- Electric furnace is divided into four categories: resistance furnace, induction furnace, arc furnace and special electric furnace according to the different ways of electric heating.

- Q: What are the advantages of a vacuum furnace?

- High degree of integration of mechanical and electrical. On the basis of the improvement of temperature measurement and control accuracy, the workpiece movement, air pressure regulation, power adjustment can be programmed in advance, and quenching and tempering are carried out according to the steps.

- Q: How to use industrial furnace equipment?

- The protection device of the exposed transmission department shall be installed with the correct installation position. The structure is reasonable. The wire rope pulley of the furnace car shall be intact and undamaged. All the pulleys and sprockets on the furnace are in good condition, without defects and flexible in rolling.

- Q: What is an industrial furnace pit?

- The creation and development of industrial kilns play an important role in the progress of mankind. Chinese appeared more perfect in the Shang Dynasty copper smelting furnace, furnace temperature is up to 1200 DEG C, up to 0.8 meters in diameter kiln stove.

Send your message to us

Small induction furnace for gold/silver melting

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords