Slab copper mould plate/continuous casting copper mould plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Description

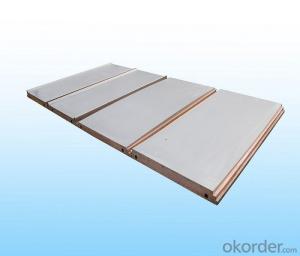

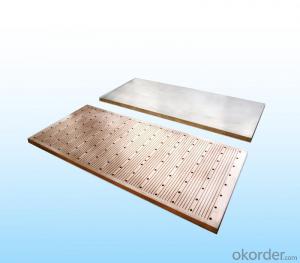

We are supplying High Slab copper mould plate with Size range Length 350-3800 Width 700-1000mm ,Thickness 30-75mm, Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.which are the world's most Renowned and Reputed;

We supply Copper Moulds of Highest Quality, ensuring Maximum Life, excellent Heat Resistivity and smoothest Casting Operational efficiency.

CNBM, is the leading professional designer and manufacturer for copper mould tubes & plates as well as the complete sets of equipments & spare parts used for hundreds of domestic and abroad steel plants. The copper moulds supplied by CNBM adopt advanced European technology. Nowadays, CNBM is one of the largest copper moulds supplier and exporter with more than 30% market share in domestic market and 5% in the world market. We commit to supply products with world-class quality, competitive price, flexible payment terms, speedy delivery and excellent service, and we can also give technical guidance to help our customers to reduce the cost and increase the productivity. We have got high reputation from various customers all over the world.

2.Main Features

Our design and manufature capacity: with slot single taper, double taper, triple taper, quadruplicate taper, parabolic taper and various of continous taper high effiency copper mould tube.

We are supplying High Slab copper mould plate with Size range Length 350-3800 Width 700-1000mm ,Thickness 30-75mm, Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

Steady and high quality,

We can design as per the customer’s specific requirements.

With lots of export expriences all around the world,

Fast shipment; 30-40days for production;

Packing : Strong, export worthy wooden cases.

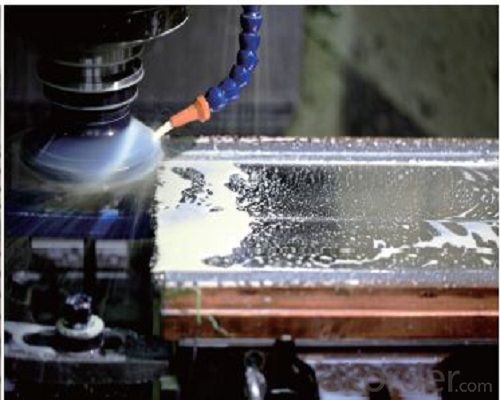

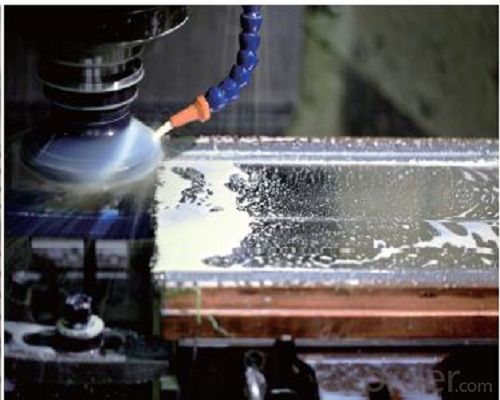

3. Images

4.Specification

Slab

Length 350-3800mm

Width 700-1000 mm

Thickness 30-75mm

Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

* We can design as per the customer’s specific requirements.

- Q: I‘m asking for the card, NOT a design for the card. Some cards are made out of card stock or construction papers or any kind of paper and what indigenous material can i use as an alternative to these papers?

- A thin piece of birch bark Copper, tin or aluminum sheeting

- Q: What is the first philippine alphabet?

- Dr.'s do recommend it, however, I had morning sickness throughout my whole 2ND pregnancy and couldn't keep hardly anything down. Unfortunately, I stayed so sick the little weight I had gained was lost by the time I was in my 8th month. FORTUNATELY, I had a very healthy baby boy. He still is healthy at 11yrs, he's rarely sick. The prenatal plus might have enough iron in it, too much isn't good either.

- Q: This lab was about aluminum reacting with copper (II) chloride. On day one of the lab, we allowed aluminum to react with copper (II) chloride in a beaker filled with water. On day two, we removed the chunks of wet copper (the product) from the beaker and put them on a sheet of filter paper. Finally, on day three, we measured the mass of the dry copper. It was determined that aluminum was the excess reagent and copper (II) chloride was the limiting reagent. There are a few post lab questions that I need help with. Here is a chemical equation to help you: 2Al+3CuCl2 -gt; 2AlCl3+3Cu Which gas was produced in this lab (in Day 1)? State evidence of a gas being produced? Why did the blue color of the solution disappear? (Day 2) Describe the appearance of the product. (Day 2 before filtering) Why did the product have that particular appearance? Thanks for the help!

- Hi Evy, 2 Al(s) + 3 Cu(2+) + 6 Cl(-) 3 Cu(s) + 2 Al(3+) + 6 Cl(-) these are the ions Cu(2 +) that give the blue color to the solution . . . ! All Cu(2 +) ions reacted because Al is in excess . . . that is why the blue color disappears . . .

- Q: And is there anyway to skip that, like copper electroplating.

- that is done by some bulk bullet casting companies but the amount of time and labor involved, plus the cost of copper would make it a worse choice. There are some pretty simple lubing methods out there. I recall one where it's basically a liquid lube and you just lay a bunch of bullets on a cooking sheet and put the lube on, roll em back and forth and then stand em up and let em dry. I want to say there was some kind of spray lube for bullets(not case lube) but I can't recall for sure if it worked or not. I really think if your going to the trouble of casting your own bullets it isn't much more effort to use a sizing/lube die. Especially as you are going to need to do the sizing step anyway a lot of the time if you are trying to make truly accurate ammunition.

- Q: or many small sheets of metal? i looked at home depot and they didn‘t have it. are there any other places?

- i think of it incredibly is a splash intense. Calipers and pads would desire to be approximately one hundred to a hundred and fifty for aspects. yet another 50 to have the discs became. it rather is a splash intense for a 2 hour restoration. desire i can make that type of money.

- Q: i am such a suckerand im always the last to knowmy insides are copperid kill to make them goldconversation got me hereanother night alone in the city

- Fall Out Boy - Sending Postcards From A Plane Crash (Wish You Were Here)

- Q: I am remodeling my basement, and I really didn‘t want to do anything to the ceiling at all, but I realized that would just leave open top sheet rock at the tops of walls. I really don‘t want to do a sheet rock ceiling in case I need to open it back up to repair pipes or wiring, and I really hate drop ceilings. Suggestions? I‘ve heard everything from cargo nets to orange construction fence. (really?)

- How about a ceiling grid like you would use for a dropped ceiling, but instead of acoustical tile use 1/2 inch thick drywall. I've seen it done and it looks very finished, yet everything is accessible above it since you can remove and replace the 2 foot x 4 foot pieces of drywall if you need to. Finish the drywall pieces with the paint of your choosing after you cut them but before you install them in the grid. You'll have to attach the ceiling grid securely to the joists above because drywall is a lot heavier than the tiles that are normally used.

Send your message to us

Slab copper mould plate/continuous casting copper mould plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords