Thin slab copper mould plate used on continuous casting machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 400 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Description

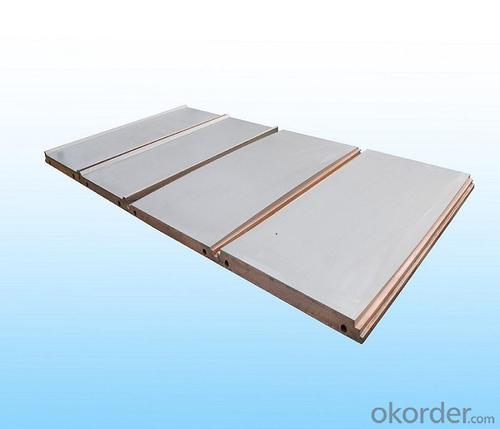

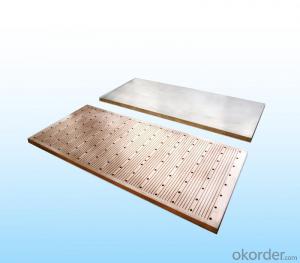

Thin slab copper mould plate is one our another mian products, the Size range Length1200-2000 Width 1100-1200mm , Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

We supply Copper Moulds of Highest Quality, ensuring Maximum Life, excellent Heat Resistivity and smoothest Casting Operational efficiency.

We are the leading professional designer and manufacturer for copper mould plates & tube.

The copper moulds supplied by CNBM adopt advanced European technology. Nowadays, CNBM is one of the largest copper moulds supplier and exporter with more than 30% market share in domestic market and 5% in the world market.

2.Main Features

Steady and high quality,

Packing : Strong, export worthy wooden cases. High quality products and excellent service.

We commit to supply products with world-class quality, competitive price, flexible payment terms, speedy delivery and excellent service, and we can also give technical guidance to help our customers to reduce the cost and increase the productivity. We have got high reputation from various customers all over the world.

We are supplying High Slab copper mould plateSize range Length1200-2000 Width 1100-1200mm , Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

We can design as per the customer’s specific requirements. Fast shipment; 30-40days for production;

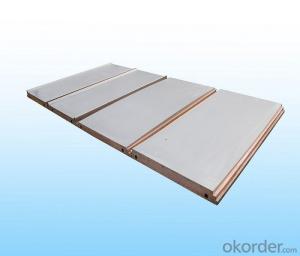

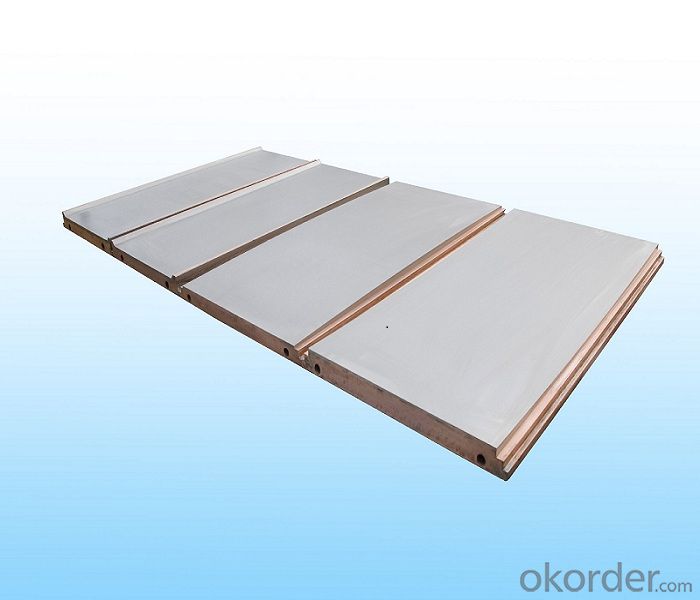

3. Images

4.Specification

Thin slab

We can design as per the customer’s specific requirements.

Length 1200-2000mm

Width 1100-1200 mm

Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

We can design as per the customer’s specific requirements.

- Q: how to create solar panels?

- Of course like everything else we do, it won't be considered cost effective until a large chunk of something plows into a shuttle or the space station and wipes out the crew or a segment there-of.

- Q: Why? Using an appropriate model of bonding please explain

- Only a brittle element would shatter on being hit by a hammer. copper as we all know is a solid and a metal. It possesses the property of malleability i.e. it can be beaten into thin sheets. The interatomic space between the atoms of a metal like copper is very small and hence they don't disintegrate or shatter when hit with a metal.

- Q: A foundry worker places a 5.78 kg sheet of copper at a temperature of 17°C on top of a 16.8 kg sheet of silver at 65°C. Assume no heat is lost to the surroundings.

- The heat energy that is gained by the copper is equal to the heat energy that is given off by the silver. The following specific heats are from a table in my physic’s book. Copper 387 J Silver 234 For copper, Q 5.78 * 387 * (Tf – 17) 2,236.86 * Tf – 38,026.62 For silver, Q 16.8 * 234 * (65 – Tf) 255,528 – 3,931.2 * Tf 2,236.86 * Tf – 38,026.62 255,528 – 3,931.2 * Tf 6,168.06 * Tf 293.554.62 Tf 293,554.62 ÷ 6,168.06 The final temperature is approximately 47.6?C.

- Q: I have this round dining table. Its iron base and wood top. The wood top is dented and the venner is damaged. I thought it would be cool to cover it with copper. The table is between 3 and 4 ft in diameter (can't recall exactly right now).What would be the best way to go about this? sheet vs. rolls. and any application advise would be helpfulthanks!

- That sounds beautiful actually! I have done similar treatments to other objects for clients in my home remodel business. For an application like this, I recommend using a paint or a glaze. You can find all sorts of these at your local craft store. Read the instructions carefully to make sure you pick a product that will stick and that you use the proper type of seal so it doesn't start flaking off. Guilding powders and sheets are also great, but can be very expensive. Make sure you sand the top down so that the paint will adhere properly. Another idea if you want to get back to a truly smooth surface is to consider tiling the table top. You can find tile in every metallic color under the sun and the even have metallic grouts available now (I know the brand Laticrete has a great selection.even available in an epoxy which would be perfect for a durable, stain/mold/mildew proof finish). Yet another possibility, buy thin metallic tiles that are actually intended for use in ceilings and back splashes. They are easy to cut and install but they will probably not be durable enough to withstand heavy use. To solve this issue, have a piece of glass cut in the same size or slightly larger than your table top with smooth edges and place on top of your application. This will give you the look you are going for without worrying about wear and tear and ease of maintenance. Hope this helps! Scarlett

- Q: What tools and techniques are best?

- I've taken a metal working class which covered repousse, which I think is what you want to do. If you have no metal working experience taking a class would probably be best. Places which offer jewelry classes may also offer this. Otherwise the material of choice to start with are copper sheets, they are easy to anneal. Annealing is relieving stresses in the metal by heat, that makes the metal soft. Working it will harden it again. Really works well with copper. Metal may need to be pickled so oxides don't get worked into the metal. Pitch is used to hold the metal sheet in place (at least for small ones). You will need a variety of chasing tools and a small hammer. You can make chasing tools yourself from toolsteel, but read up about tempering steel before you try it and before you buy tool steel. As there are a lot of details to be covered, and I am not really into writing pages of it down I recommend reading a book about it. Generally a good book about sheet metal working is this one: Silversmithing by Rupert Finegold and William Seitz.

- Q: How to weld thick copper plate?

- The welding methods of copper are various, and the welding methods of different copper products are also different. The commonly used methods are manual welding, carbon arc welding, manual arc welding and argon arc welding of four methods, the large structure can also be used for automatic welding.

- Q: A square hole 8.00 cm along each side is cut in a sheet of copper. Calculate the change in the area of this hole resulting when the temperature of the sheet is increased by 48.0 K.We don‘t know where to start on this.

- The starting area of this circle is a(pi)r^2 , where r 4cm (or one-half of L) You need to look up, in your book most likely, the coefficient of thermal expansion for copper. It is most likely given in degrees Celsius, so make sure to convert your Kelvin temperatures, accordingly. You should also be able to identify the thermal expansion equation: the change in length of a material is equal to the initial length of the material multiplied by the coefficient of thermal expansion for the material multiplied by the change in temperature of the material. This gives you the CHANGE in the LENGTH of the material. Now, calculate the area of the circle after expansion: A (pi)R^2 , where R is equal to half of the sum of L plus the change in L: R [L + (change in L)]/2 Finally, subtract these two quantities to find your change in area: change in area: ( A - a ) pi(R^2 - r^2) pi([(L/2)^2] - [(L + change in L)/2]^2]) Love the physics.

- Q: we got a sheet with a problem and you have to determine the equation and there is 3 that i cannot figure out.When dirty water is boiled for purification purposes, the temperature is brought up to 100 degrees c for 15 minutes.If a copper coil is placed into a solution of silver nitrate, silver crystals form on the surface of the copper Additionally, highly soluble copper (i) nitrate is generated.i started to get this one but it ended up not working out this is what i gotCu(NO3)2 + AgNO3 Cu(NO3)2When a chunk of palladium metal is grounded into a very fine powder and heated to drive off any atmospheric moisture, the resulting powder is an excellent catalyst for chemical reactions.

- in NY ya have 80k total on a tractor trailer, that leaves 16.7k. math wise ya ok. IDK what ya truck id rated for or ya local laws

Send your message to us

Thin slab copper mould plate used on continuous casting machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 400 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords