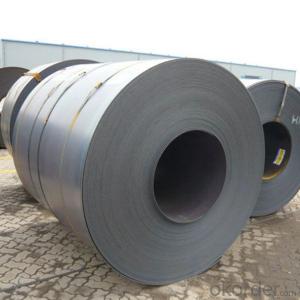

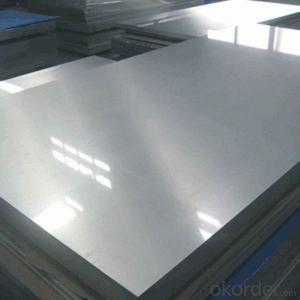

Rolled Steel Sheets HRC Q235 for Sale in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 55 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of steel sheets:

1,Corten A\B steel plate

2,hot rolled steel

3,size:2.0-150*100-2000mm *3000-8000mm or coil

Festures of steel sheets:

1. Packing: a. Small size: in bundles

2. Big size: in bulk

3. in plastic packing or as per customer request

4. Delivery time: a. Normal size: within 7days send from warehouse directly

Specifications of steel sheets:

| Product | TOP KING alibaba China manufacturer HOT ROLLED STEEL SHEETS boats for sale |

| Place of origin | Tianjin,China mainland |

| MOQ | 10 ton |

| Thickness | 1mm-200mm |

| Width | 1000mm-3000mm |

| Length | 1000mm-12000mm |

| Application | widely |

| Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

| Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

| Tpye | Steel plate |

| Surfacing | Coated |

| Productive Technology | Hot Rolled & Cold Rolled |

| Price | FOB USD 500-900 per ton |

| Port | TIANJIN |

| Payment Terms | L/C,T/T,Western Union |

| Product Ability | 10000 tons per month |

| Delivery | 10 days after deposit or according to customers' quantity |

| Packing | standard seaworthy export packing or as the request of customers |

Images of steel sheets:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: HISTORY OF PHOTOGRAPHY QUESTIONS HELP?

- 1 Salted paper can only made by contact; much less sensitive 2 Nothing to do with photography 3 Calotype used a paper negative and colodion a glass 4 Reproduction 5 Precission

- Q: What is the difference between copper plate T2 and T3?

- Transformation of the construction of the national grid cannot do without using power distribution cabinet and other facilities, power grid load flow to increase the popularity of the reform will strengthen reflect the installation of T3 products is the China electrical load, Wenzhou all but the market can not imagine is inferior line market, the competition of electric field is used in T3

- Q: I have a sheet with some homework Questions on it.I am slightly confused, and do not understand what it is asking.It says that an experiment has taken place with heating metals, an electric heater has been fitted and a thermometer.below this explanation there is a table, with metals: aluminium, and copper.Then the start temperature in degrees c. and end temperature. Then energy given to metal in Joules.Question 1 is:Compare Block A and Ba. what is the input variable?The metal is Aluminium in A, with a mass of 200g and start temperature of 21 degrees C. and end temperature of 51 degrees C the energy given at the end is 53,900 joules!‘B‘ is exactly the same temperatures but half of the mass and half of the energy given!could someone please explain the input and outcome variables!I‘m sorry it‘s so long and confusing, but I don‘t know what else to do!x

- This looks like an experiment to determine the 'specific heat capacity' (sometimes referred to as 'specific heat') of aluminium. The equation relating heat energy to specific heat capacity, where the unit quantity is in terms of mass is: ΔQ mcΔT where ΔQ is the heat energy put into or taken out of the substance, m is the mass of the substance, c is the specific heat capacity, and ΔT is the temperature differential where the initial temperature of the reaction is subtracted from the final temperature. It is quite usual in an experiment to vary one input which is expected to affect the measurement in exactly one distinct way only. In the example you have given, it is the mass that is the input variable as the temperatures are the same (i.e. the temperatures do not vary). We could have kept the mass constant and varied the temperatures in which case the input variable would have been ΔT. The 'outcome variable' is the energy required, ΔQ, to achieve the difference in temperature. Hope this helps.

- Q: Has anyone tried to build their own solar panel yet?

- The copper panel can be made with 78 OD copper tubing soldered to a 114 header, top and bottom . A 1 T at the bottom for inlet glycol supply and a 1 T at the top for hydronic return .This way you can use one pan-ell or a series of panel ls in a row . Soldered to flat 1|8 thick flat copper . You need a frame and room for expansion . The glass is the problem .Solar glass is Prism shaped and can not be cut .The slightest crack will make the whole sheet Shatter .

- Q: The question is: What is the mass copper metal that can be prepared from the reaction of 1.25 g of aluminum metal with excess CuSO4 according to the following reaction: 2Al(s)+3CuSO4(aq)-----3Cu(s)+Al2(SO4)3(aq)The answer is mol of Al0.04633 mol, mol of Cu0.06949 mol, grams of Cu4.42How was this figured? I am studing for a final and all the instructor gave us was a review sheet with qa. I have no idea how or what these questions are figured. any help would be great.

- This is all about stoichiometry. I'm not going to do all the math, but here's how to do it. * Look at the balanced equation and see that 2 moles Al(s) and 3 moles CuSO4 makes 3 moles Cu(s) and 1 mole Al2(SO4)3. So, always work it mole. * Next, to get the mass of Cu metal that is formed from 1.25 g of Al metal, you convert the 1.25 grams of Al to moles of Al. Then knowing that 2 moles Al produces 3 moles Cu, you can then calculate moles of Cu that can be formed. Note that CuSO4 is in excess, meaning that ALL the Al(s) will react. * Now that you have the moles of Cu metal calculated, you can convert that to mass of Cu(s) by using the atomic weight of Cu.

- Q: What method is used to solder the brass plate before it is deformed?

- If there is no deformation at all, we can only use the method of "brazing in the furnace", that is, the flux is applied to the interface and then fed into a large furnace which can be controlled by temperature, and then heated to the brazing agent to melt and cool. But this approach is generally not easy to implement.If the requirement is not high, we can use MIG arc brazing, choose lower melting point of aluminum silicone welding wire, using short circuiting welding specification, so that small heat input, small deformation. If you can use special CMT welding machine is the best, that is, equipment prices are high, to about 200 thousand yuan.

- Q: can you sujest low resistance around 10^-9?

- Very tough. A sheet of copper 3 cm square and 1 mm thick will have a resistance close to 10^–9 Ω between its two flat faces ( that is , with the connectors separated by 1 mm of copper. ) . But that is the problem the connectors will have much more resistance and totally swamp the tiny resistance of the Cu sheet. What on earth do you what it for ?

Send your message to us

Rolled Steel Sheets HRC Q235 for Sale in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 55 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords