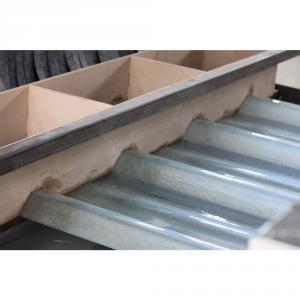

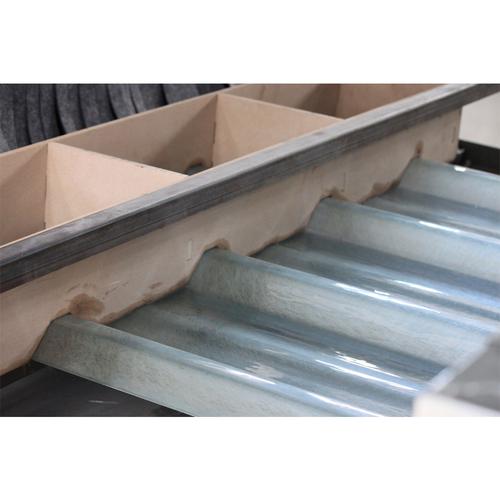

Skylight FRP Fibreglass Translucent Transparent Corrugated Roof Panel Machinery

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 SET

- Supply Capability:

- 2 SET/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP roofing sheet advantage

1.Corrosion Resistance

2.Strong Strength

3.Aging Resistance

4.Chalking Resistance

5.Self-cleaning

6.Yellowish Resistance

7.Cheaper Maintenance

8.Excellent Performance

Application of FPR sheet

1. Animals and plants in greenhouse lighting;

2. Industrial and civil building roofs and walls day lighting, such as factory building day lighting band, the hotel, gymnasium, swimming hall, parking lot;

3.Cooling tower;

4.Refrigerated truck body;

5.Decorative sheet(any pattern is no problem);

6.Mobile house and use at wall

Machine characteristics:

1, Apply high precision import forging doctor blade, smaller error, Thin & even gel coat coating.

2, Special Gutter shape cutting technology, The cutting track can be set based on customer requirement. Cutting with less noise& dust,the cutting surface is clean & tidy.

3, Impregnation platform multi-line independent temperature control, temperature control is precise, able to better adapt change of ambient temperature, quick impregnation, speed of production could be improved effectively;

4, Pulse free metering system, accurate metering & wide flow rate adjustment range. It can add powder filler.

5, Easy operation based on PLC intellectual control system. Operate by two computers, the production task and equipment operating data is faster and intuitional. Only short-term training can make operators complete production independently.

6, Three separate ovens for temperature control designed by Dnuo, unique temperature control arithmetic, make oven heating fast, temperature control precise. Which improve quality of products, reduce energy consumption and shorten the preparing time effectively. This way makes sheets curing better.(patent number: ZL 2014 2 07 31923.x)

7, Metering control system and Roving chopper speed can be synchronous with the production line.

8, All the machine parts adopt international standard steel make machine with high stability.

9, System failure can be automatically alarmed and show fault point. Make maintenance easily.

10,Particular parts adopt special purpose wire, durable in use.

Q&A

Q: Can I order the product with special size?

A: Of course you can, also we will produce the products according to your detail requests

Q: Why we are your best choice?

A: We have direct factory and many years of export experience, and offer the best price with high quality product, timely delivery, also have good after-sales service, therefore with good reputation on boards and with many clients have good long-term business relationship.

- Q: What steps are required during the installation of the cement tile machine?

- Board installation and commissioning: the board and the plate machine board axis, along the axis direction adjustment board machine so that the board machine in the hanging board down when the tray does not collide with the board, adjust the board lift Induction switch position to determine the number of yards of brick, up to no more than 3 board.

- Q: Analysis on the Problems of Cement Shade Machine

- Peeling off all the foam, peel off part; follow the construction specifications, do grass-roots waterproof, before the construction of the grass-roots cracks to repair , To ensure that the grass-roots moisture content in line with construction requirements.

- Q: The processing method of the tile machine

- Ingredients when the sand too much, resulting in tile sticky enough, when there is cracks in the cracks.

- Q: What are the advantages of cement tile machine?

- the use of advanced original, preferably configured. PC, machine, electricity, liquid, gas, integrated control, automatic control. Change the traditional molding machine "guide sleeve" as "four pole" precision positioning, machine performance is more stable and reliable, productivity, higher yield, more than similar foreign product level.

Send your message to us

Skylight FRP Fibreglass Translucent Transparent Corrugated Roof Panel Machinery

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 SET

- Supply Capability:

- 2 SET/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches