Skid Aluminum Coil for Coated Aluminum Honeycomb Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

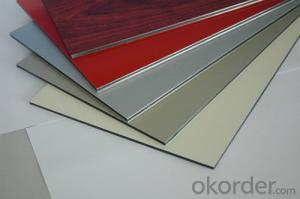

Coated Aluminium Coil/Roll For Aluminium Honeycomb Panel

Description

Alloy | 1060, 1100, 3003, 8011, etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.05mm to 3.0mm |

Width | Standard width:1240mm |

Special width:1300mm, 1520mm, 1570mm, 1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, ACRYLIC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness(pencil resistance) | More than 2h |

Coating adhesion | 5J (EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility(T-bend) | 2T |

MEK resistance | More than 100 |

Advantage | 1.High temperature resistant 2.Weathering resistant 3.Scrubbing resistant 5.Acid or alkali proof 6. Fireproof 7.Light weight material is easy to construct and install |

Out package | Wooden splint with export standard |

Application | ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels, etc |

Manufacturing

Decoiler → Accumulator →Tension Leveler →Acid & Alkali Cleaner → Rinse →Conversion Treatment → Priming coater →Infrared Curing Oven →Main coater →Floatation Curing Oven →Strippable Film Applicator → Exit Accumulator → Recoiler

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: What are the different alloy grades used in aluminum coils?

- There are several different alloy grades commonly used in aluminum coils, including 3003, 5052, 6061, and 7075. These grades have varying levels of strength, corrosion resistance, and weldability, making them suitable for different applications in industries such as automotive, construction, and aerospace.

- Q: What is the typical width tolerance for aluminum coils?

- The typical width tolerance for aluminum coils can vary depending on the specific requirements and industry standards. However, a commonly accepted width tolerance for aluminum coils is typically ±0.005 to ±0.020 inches.

- Q: How are aluminum coils protected against scratching and abrasion?

- Aluminum coils are typically protected against scratching and abrasion through various methods, such as applying a protective coating or film. This coating acts as a barrier, shielding the surface of the coils from potential damage during handling, transportation, and processing. Additionally, some manufacturers may use protective packaging materials, such as plastic or cardboard, to further safeguard the coils against scratching and abrasion.

- Q: What are the different surface treatments available for aluminum coils?

- Aluminum coils offer a range of surface treatments, each with its own advantages and applications. The options include: 1. Mill Finish: This is the untreated standard surface of aluminum coils. It has a dull appearance and is suitable for industrial or structural uses where aesthetics are not a priority. 2. Anodizing: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of aluminum coils. This treatment improves corrosion resistance, durability, and appearance. Anodized coils are often used in architectural applications like building exteriors and window frames. 3. Paint Coating: Various paints can be applied to aluminum coils to enhance their appearance, protect against corrosion, and provide additional functionality like heat reflection or insulation. Different thicknesses and finishes are available, catering to general use or specific industries like automotive or aerospace. 4. Brushed Finish: This treatment involves brushing abrasive materials onto the surface of aluminum coils to create a textured finish. Brushed coils have distinct patterns and are commonly used in decorative applications, interior design, or signage. 5. Embossed Finish: Aluminum coils can be embossed with patterns or textures to enhance their appearance or functionality. This process alters the surface, creating raised or recessed designs. Embossed coils find applications in architecture, automotive, and packaging. 6. Laminating: Aluminum coils can be laminated with various materials like films or foils for added protection, insulation, or decorative effects. The type of lamination material used determines the appearance, durability, or functionality enhancements. These examples highlight the available surface treatments for aluminum coils. The choice depends on specific requirements such as aesthetics, corrosion resistance, durability, or functionality. Selecting the appropriate treatment ensures the desired performance and longevity of the coils in their intended use.

- Q: My budgies took at bath in an aluminum pie tin today. At first they bit it just because it was their first time. Should I be worried that they might get poisoned?

- poisoned by what? if aluminum was poisonous why are aluminum foil and aluminum cooking utensils legal?

- Q: How do aluminum coils perform in saltwater environments?

- Due to their innate resistance to corrosion, aluminum coils exhibit exceptional performance in saltwater environments. Unlike other metals, aluminum develops a protective oxide layer upon exposure to saltwater, effectively creating a barrier that prevents further corrosion. This durable and long-lasting oxide layer acts as a shield against the harsh effects of saltwater, guaranteeing the longevity and efficiency of aluminum coils in marine applications. Furthermore, the lightweight nature and high thermal conductivity of aluminum coils make them widely favored for use in heat exchangers and condensers within saltwater-based cooling systems. In conclusion, aluminum coils are extensively relied upon and highly efficient in saltwater environments, establishing them as the preferred choice for a range of marine applications.

- Q: Can aluminum coils be used in automotive applications?

- Yes, aluminum coils can be used in automotive applications. Aluminum coils are lightweight, which makes them an excellent choice for automotive manufacturers as it helps to reduce the overall weight of the vehicle. This, in turn, can improve fuel efficiency and performance. Additionally, aluminum coils have excellent heat conductivity, which is crucial in automotive applications where heat dissipation is important. Moreover, aluminum coils have good corrosion resistance, which is particularly beneficial in automotive applications where vehicles are exposed to various weather conditions and road salts. Overall, the use of aluminum coils in automotive applications can provide several advantages such as weight reduction, improved fuel efficiency, better heat dissipation, and enhanced corrosion resistance.

- Q: Please tell me the model of antirust aluminium coil, it is better to have a detailed introduction. Thank you。 Shandong production of rust resistant aluminum coil manufacturers

- We are Ji'nan excellent Aluminum Co., Ltd., anti rust aluminum roll, now domestic generally use 3003 material, the price is now 19500 yuan / ton.3003 aluminum coil for AL-Mn alloy, is the most widely used of a rust resistant aluminum, density is 2.73.

- Q: This question asks about the differences between 3D printed aluminum coils and traditionally manufactured aluminum coils.

- <p>Yes, there are differences between 3D printed and regular aluminum coils. 3D printed aluminum coils are manufactured using additive manufacturing, which allows for complex geometries and customization. They can be produced with less material waste and can be designed for specific applications. Traditionally manufactured aluminum coils, on the other hand, are typically made through processes like rolling, which may not offer the same level of design flexibility. 3D printed coils may have different mechanical properties due to the layer-by-layer manufacturing process, potentially resulting in varying strength and durability. Additionally, 3D printed coils might have a higher cost due to the specialized equipment and materials required for additive manufacturing.</p>

- Q: i have recently received a task to research the recycling processes of aluminum ..... the task also asks to STATE ALL RELEVANT MATHEMATICAL OR/AND CHEMICAL EQUATIONS ...when i researched the task i found how aluminum is recycled, but i couldnt find the relevant equations ...can you please help meall answers are really appreciated

- Aluminium recycling is the process by which scrap aluminium can be reused in products after its initial production. The process involves simply re-melting the metal, which is far less expensive and energy intensive than creating new aluminium through the electrolysis of aluminium oxide (Al2O3), which must first be mined from bauxite ore and then refined using the Bayer process.

Send your message to us

Skid Aluminum Coil for Coated Aluminum Honeycomb Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords