Aluminum Strips - Similar Products, Contact Supplier, Leave Messages, Colour Coated Embossed Aluminum Sheet and Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

By 1895, the metal was being used as a building material as far away as Sydney, Australia in the dome of the Chief Secretary's Building.

With the explosive expansion of the airplane industry during World War I (1914–1917), major governments demanded large shipments of aluminium for light, strong airframes. They often subsidized factories and the necessary electrical supply systems.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

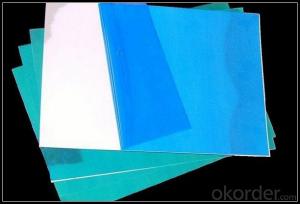

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Are aluminum strips suitable for manufacturing automotive components?

- <p>Yes, aluminum strips are commonly used for automotive parts due to their lightweight, high strength, and corrosion resistance. They are utilized in various components such as engine parts, body panels, and suspension systems to reduce weight and improve fuel efficiency. Additionally, aluminum's recyclability makes it an environmentally friendly choice for the automotive industry.</p>

- Q: Is it possible to utilize aluminum strips in construction for decking or fencing purposes?

- <p>Yes, you can use aluminum strips for decking or fencing projects. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It is lightweight, easy to install, and can withstand various weather conditions. Aluminum strips can be used to create modern and sleek designs, and they are also recyclable, making them an environmentally friendly option. However, it's important to ensure that the aluminum strips are of suitable thickness and quality to bear the weight and stress expected in your specific project.</p>

- Q: Is it possible to use aluminum strips for exterior trim applications?

- <p>Yes, aluminum strips can be used for exterior trim. They are lightweight, durable, and resistant to corrosion, making them suitable for outdoor use. Aluminum trims are low maintenance and can withstand various weather conditions without rusting. They are also available in a variety of colors and finishes, allowing for flexibility in design. However, it's important to ensure proper installation and use high-quality materials to guarantee longevity and performance.</p>

- Q: What are the potential safety hazards associated with the use of aluminum strips?

- <p>Aluminum strips are generally safe to use, but there are a few safety concerns to consider. They can be sharp and cause cuts if handled improperly. Additionally, aluminum dust, if inhaled, can cause respiratory issues. It's important to handle aluminum strips with care, wear protective gloves, and avoid inhaling dust. In the case of electrical applications, ensure that aluminum strips are properly insulated to prevent electrical shocks. Always follow safety guidelines and manufacturer instructions when using aluminum strips.</p>

- Q: This question asks about the various color options available for aluminum strips.

- <p>Aluminum strips are available in a variety of colors to suit different applications and aesthetic preferences. Common colors include silver, which is the natural color of aluminum, black, white, and clear anodized. Additionally, they can be coated or anodized in other colors such as gold, bronze, blue, red, and green. Custom colors are also possible with specialized coating or anodizing processes. The choice of color can depend on the specific use of the aluminum strip, such as for decorative purposes, architectural applications, or industrial uses where color coding is required.</p>

- Q: Is it possible to substitute metal sheets for asphalt shingles on a roof?

- <p>Yes, you can use metal sheets to replace asphalt shingles on your roof. Metal roofing is a durable and weather-resistant alternative to asphalt shingles. It offers benefits such as longevity, energy efficiency, and low maintenance. However, it's essential to consider the weight of metal sheets compared to shingles, as it may require structural reinforcement. Additionally, proper installation by a professional is crucial to ensure the roof's integrity and to maximize the benefits of metal roofing.</p>

- Q: Is it appropriate to use aluminum strips for constructing outdoor furniture?

- <p>Yes, you can use aluminum strips for outdoor furniture. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It doesn't rust and can withstand various weather conditions, making it suitable for outdoor use. However, ensure that the aluminum is of high quality and treated to resist UV rays and other environmental factors to prolong its lifespan and maintain its appearance.</p>

- Q: What are the typical applications of aluminum strips within the construction industry?

- <p>Aluminum strips are commonly used in construction for various purposes due to their strength, durability, and lightweight properties. They are often used as a component in the manufacturing of aluminum windows and doors for their high strength-to-weight ratio and resistance to corrosion. Aluminum strips are also utilized in the construction of curtain walls, which are the outer coverings of buildings, for their aesthetic appeal and low maintenance requirements. Additionally, they are employed in roofing systems for their ability to withstand harsh weather conditions and resist rust. Furthermore, aluminum strips are used in the framing of buildings and in the creation of structural supports due to their high tensile strength.</p>

- Q: What is the minimum thickness that can be achieved when manufacturing an aluminum strip?

- <p>There is no absolute limit to how thin an aluminum strip can be made, but the practical limit is determined by the manufacturing process and the intended use of the strip. Modern technology allows for the production of aluminum strips as thin as a few micrometers. However, the thinness is constrained by factors such as material strength, ductility, and the specific application requirements. For instance, in the electronics industry, very thin aluminum strips are used for conductors, while in other applications, thicker strips might be necessary for structural integrity. The thinnest aluminum strips are often produced using techniques like rolling or extrusion, with the final thickness depending on the precision of these processes.</p>

- Q: Is it possible to use aluminum strips as a covering for window or door frames?

- <p>Yes, you can use aluminum strips to cover window or door frames. Aluminum is a durable and lightweight material that can provide a sleek finish to your frames. It is resistant to corrosion and weathering, making it suitable for both indoor and outdoor applications. Aluminum strips can be easily cut and shaped to fit the contours of your frames, and they can be painted or anodized to match your desired aesthetic. However, ensure proper installation to maintain structural integrity and weatherproofing.</p>

Send your message to us

Aluminum Strips - Similar Products, Contact Supplier, Leave Messages, Colour Coated Embossed Aluminum Sheet and Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords