Embossed Aluminum Furring Strips Sheets and Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Alumina

(2).Sulfates

(3).Niche compounds..

3. Feature of Aluminum

Many navies have used an aluminium superstructure for their vessels; the 1975 fire aboard USS Belknap that gutted her aluminium superstructure, as well as observation of battle damage to British ships during the Falklands War, led to many navies switching to all steel superstructures.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

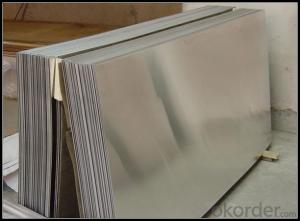

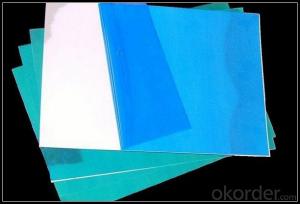

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What benefits can be gained from incorporating aluminum strips in construction projects?

- <p>Aluminum strips offer several advantages in construction, including high strength-to-weight ratio, which means they are strong yet lightweight. They are also resistant to corrosion, making them suitable for outdoor applications and harsh environments. Aluminum strips are easy to work with, allowing for easy installation and customization. They are also energy-efficient, as they reflect heat and can help reduce cooling costs. Additionally, aluminum is recyclable, contributing to sustainability and reducing waste.</p>

- Q: How to distinguish between good and bad aluminum bands?

- Compare the flexibility and strength of aluminium pinch plateThe differential method is simple: take a piece of aluminum buckle, with his hand he bent aluminum buckle not good will easily be bent, and will not return to its original shape, and good bending to aluminum buckle requires effort, and after bending, will rebound to a certain extent, the difference between the strength and toughness this is the aluminum. After the installation of a good aluminum pinch plate, there will be no bending or middle fall.

- Q: This question asks for a list of various types of aluminum components used in the automotive industry.

- <p>Aluminum is widely used in the automotive industry due to its lightweight and high strength. Different types of automotive aluminum parts include engine components such as cylinder heads and blocks, transmission housings, suspension parts like control arms and knuckles, wheels and rims, body panels, and doors. Other applications include heat exchangers, radiators, and various brackets and structural components. The use of aluminum can significantly reduce the weight of vehicles, improving fuel efficiency and performance.</p>

- Q: Is it possible to apply paint to aluminum strips?

- <p>Yes, aluminum strips can be painted. However, proper surface preparation is crucial for good adhesion and durability of the paint. This typically involves cleaning the aluminum to remove any grease or contaminants, followed by etching or using a primer designed for aluminum to promote better paint adherence. After priming, the aluminum can be painted with a suitable paint, such as acrylic or epoxy, which are known for their compatibility with metal surfaces. It's important to follow the manufacturer's instructions for the specific paint and primer used to ensure the best results.</p>

- Q: This question asks about the impact of aluminum strips on the performance of vehicles. It seeks to understand how these strips influence the vehicle's operation and efficiency.

- <p>Aluminum strips can affect vehicle performance in several ways. They are often used in the construction of lightweight vehicles to enhance fuel efficiency by reducing overall weight. Aluminum's high strength-to-weight ratio makes it ideal for vehicle components, improving structural integrity without adding excessive weight. Additionally, aluminum strips can be used in heat exchangers for cooling systems, which can improve engine performance by maintaining optimal operating temperatures. However, the use of aluminum strips must be balanced with considerations of cost, corrosion resistance, and recycling potential, as these factors can also influence vehicle performance and lifecycle costs.</p>

- Q: Can aluminum strips withstand harsh conditions like high humidity or salt spray?

- <p>Aluminum strips can be used in harsh environments to some extent, but their performance may be compromised. Aluminum is resistant to corrosion, making it suitable for high humidity conditions. However, in environments with significant salt spray exposure, aluminum can corrode over time, particularly due to the formation of galvanic cells when in contact with other metals. Protective coatings or anodizing can enhance its corrosion resistance, but it's not entirely impervious. Thus, while aluminum can be used in such environments, it requires proper protection and maintenance to ensure longevity.</p>

- Q: Is it possible to utilize aluminum strips in environments with high temperatures?

- <p>Aluminum strips can be used in high-temperature environments, but their performance and longevity depend on the specific conditions and the alloy type. Pure aluminum has a melting point of 660掳C (1220掳F), but aluminum alloys can be designed to withstand higher temperatures. For instance, some aluminum alloys are used in aerospace and automotive applications where they experience high temperatures. However, prolonged exposure to high temperatures can lead to material degradation, so it's crucial to select the right alloy and consider the temperature limits specified by the manufacturer for the intended application.</p>

- Q: What are the drawbacks or negative aspects associated with the use of aluminum strips?

- <p>The disadvantages of using aluminum strips include their relatively low strength compared to some other metals, making them less suitable for heavy-duty applications. They can also be prone to corrosion, especially in humid environments, which can reduce their lifespan. Additionally, aluminum strips may not be as rigid as other materials, leading to potential issues with structural integrity. Lastly, while aluminum is recyclable, the recycling process can be energy-intensive, and the environmental impact of its production, including greenhouse gas emissions, should be considered.</p>

- Q: What types of aluminum strips are more appropriate for commercial use?

- <p>Yes, there are specific types of aluminum strips that are more suitable for commercial applications. These include 1100 series aluminum strips, known for their high purity and excellent formability, making them ideal for general commercial purposes. 3003 series aluminum strips are also popular due to their enhanced corrosion resistance and formability, suitable for applications requiring moderate strength and good workability. Additionally, 5052 series aluminum strips offer good corrosion resistance and weldability, making them suitable for applications in the marine and transportation industries. The choice of aluminum strip depends on the specific requirements of the commercial application, such as strength, corrosion resistance, and formability.</p>

- Q: This question asks about the impact of aluminum strips on the thermal insulation properties of a building.

- <p>Aluminum strips can significantly affect the insulation of a building by reflecting heat and light, reducing the amount of heat that is absorbed by the building's structure. This reflective property helps to keep the interior cooler in summer and can reduce the load on air conditioning systems. However, if not properly insulated, aluminum strips can also lead to heat loss in winter, as they can reflect heat back out of the building. Proper installation with insulation materials can maximize the benefits of aluminum strips in maintaining a comfortable indoor temperature while conserving energy.</p>

Send your message to us

Embossed Aluminum Furring Strips Sheets and Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords