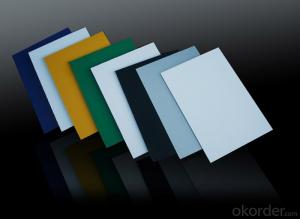

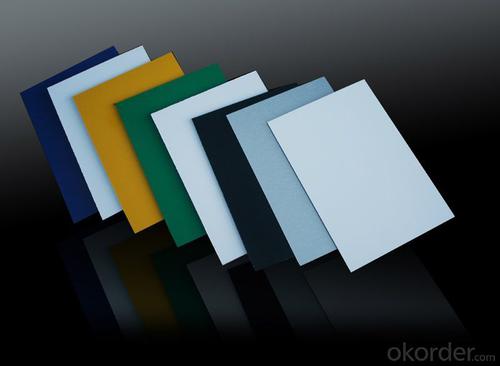

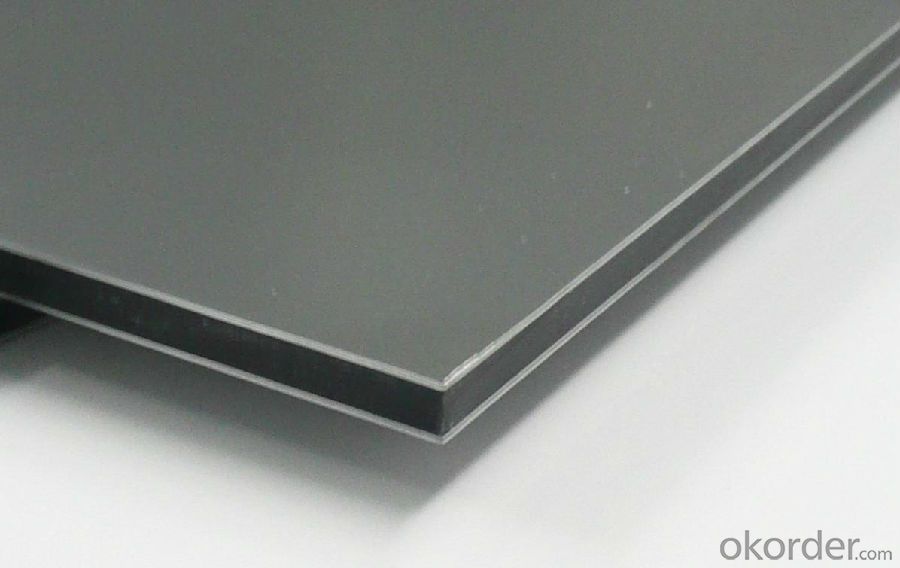

Silver Color PVDF Aluminium Composite Panels for Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Silver Color PVDF Aluminium Composite Panels for Decoration

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

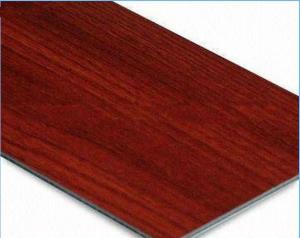

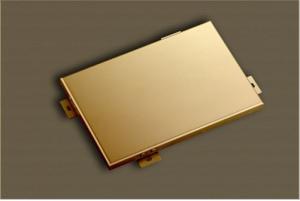

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

Production Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Coating line | WANGUAN | 2 | 4.5 | Acceptable |

| Aluminum plastic composite line | FB1600 | 4 | 3.5 | Acceptable |

| Embossing line | No information | 1 | 1.0 | Acceptable |

Testing Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Bending machine | No information | 1 | 8.0 | Acceptable |

| Visual comparison of the colour device | MSBS-1 | 1 | 5.0 | Acceptable |

| Drying oven | PULUO | 1 | 5.0 | Acceptable |

- Q: Aluminum plate price how much money?

- If you want to ensure that its long-term use, I recommend you to use aluminum veneer, in 2017 from Anhui Futian aluminum veneer factory price is the external wall of about 165 yuan. Specifically you can consult, because if the same price, then why not choose shelf life time long? Hope to help you

- Q: I stood a piece of the shop when the remaining aluminum-plastic plate plate, this aluminum layer even so, is auspicious brand, this is the situation, I do the store will fall off

- It is inevitable that customers will be in the move, the purchase of relatively poor quality products.

- Q: Can aluminum-plastic composite plates be bent 90 degrees?

- 90 degrees right angle can not! With a trimming device after trimming on the together; bending is not easy to break.

- Q: Want to buy some aluminum-plastic board, what brand is better?

- There is a regional limit, if it is in Guangdong, then personally feel that the Astrid brand of aluminum-plastic plate is good Oh! And it also makes sales of glass and aluminum roll, which may be able to meet your many requirements at once.

- Q: Aluminum plate thickness for outdoor and indoor is not the same?

- Aluminum-plastic plate materials used in outdoor facades such as curtain walls, and the thickness of the interior is certainly not the same. Specific practices are also different.

- Q: Outside the door on the head of the aluminum-plastic plate signs on the word with what material?

- Above the word, then to the art community, where they have PE or PVC material is similar to the plexiglass, choose the color after the carving, you can use the building with plastic (that is, curtain wall doors and windows sealant), direct Paste on the line.

- Q: White aluminum plate can be a new brush color? Store white aluminum-plastic board for a long time dirty, you can buy a new paint back to brush it?

- If the quality of the white aluminum plate is poor, it is hard to scrub clean for a long time.You can buy a polyester paint ...

- Q: Not clear, and we help me say the difference between them, advantages and disadvantages

- Aluminum plate is made of aluminum as the general specifications of the 300X300MM box is generally used for kitchen bathroom ceiling. Aluminum-plastic plate is a layer of two layers of aluminum plate made of a layer of plastic specifications generally 1220X2440X4MM rectangular box. Made arc is generally used for the external walls and the door and the complex corner of the decorative cylinder

- Q: How to fix the aluminum plate on the wall?

- If it is a concrete wall, you can directly use the glass glue, if it is latex paint the wall, you have to use wood to drop and then glue up the glass.

- Q: Yu Peng with aluminum-plastic plate or do a good job with a resin plate

- With aluminum plate to do a good job, with aluminum-plastic plate can make a better shape, but after repair the internal pipe fittings more trouble. Aluminum buckle plate is not easy to do modeling, but easy to disassemble.

Send your message to us

Silver Color PVDF Aluminium Composite Panels for Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords