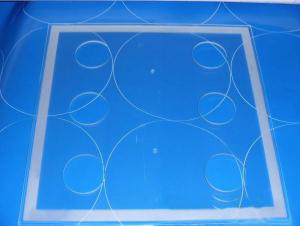

Silk Printing Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 20000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silkscreen Printing Glass is a kind of glass on which inorganic enamel is printed by silkscreen printing machines. After being printed on, it will be dried and heated under high temperature to make the enamel adhere to the glass lastingly.

Features of Silk Printing Glass:

1. Special quality

2. Clear and vivid custom-made pictures and patterns

3. Alkali-resistant and acid-resistant

4. Its color will not fade after it is heated under high temperature.

Specifications of Silk Printing Glass:

Thickness: 4-19mm

Size: 2440*4500mm

300*300mm

customized size

Applications of Silk Printing Glass:

Silkscreen Printing Glass with no pollution, great magnificence, high transmittance and high fidelity can be widely used in the fields of interior wall, exterior wall, furniture, cupboard,showcase, screen, household appliance and solar energy.

- Q: The use of quartz sand

- Derived from various magmatic rocks, sedimentary rocks and metamorphic rocks, less heavy minerals, associated minerals are feldspar, mica and clay minerals. There are two kinds of sedimentary rock genesis and metamorphic origin, the former is not obvious between clastic particles and cement, and the latter refers to quartz rocks with deep metamorphic and pure quality. The quartz veins are formed by hydrothermal action, almost all of them are composed of quartz, and they are compact and massive structures.The mineral content of quartz sand varies greatly, mainly quartz, followed by feldspar, mica, cuttings, heavy minerals and clay minerals.

- Q: What are the main raw materials for making ceramics, glass and cement?

- The main raw materials of cement clinker clinker production [four main raw materials (limestone, sandstone mainly provides Ca (mainly Si), alumina (or slag, mainly to provide Al (or Fe), iron slag, gypsum, slag etc.)]

- Q: What material is the simulation tree made of?

- The simulation tree is usually made of glass fiber reinforced steel, and some sculptures, gardens, and rockery are made of glass fiber reinforced plastic.FRP glass fiber reinforced materials, referred to as English (FRP) also known as GRP, is a new type of composite material developed abroad in early twentieth Century, it has many advantages such as lightweight, high strength, corrosion resistance, insulation, insulation, insulation etc..

- Q: How is glass made? What are the main ingredients?

- Heat treatment. Through annealing, quenching and other processes, to eliminate or produce glass internal stress, phase separation or crystallization, and change the state of glass structure.

- Q: Who has information about power plants chimneys, water glass, acid resistant concrete?

- The characteristics of water glass concrete acid: water glass acid resistant concrete with water glass as binder, sodium fluorosilicate as hardening agent, adding acid powder and acid aggregate or other additives according to a certain proportion. Features: the acid and good heat resistance, it can resist all kinds of strong oxidizing acid (such as sulfuric acid, hydrochloric acid, nitric acid) and most corrosive gases (oxygen, sulfur dioxide) erosion at high temperature (1000 DEG C) still has good acid resistance, mechanical strength and high. But this material is not resistant to hydrofluoric acid, more than 300 degrees of hot phosphoric acid and higher fatty acids or oleic acid erosion. Is a commonly used anti-corrosion material, it has a wide range of materials, acid resistance good, low cost advantages. Its disadvantages are no alkali resistance, poor impermeability and water resistance, complex construction, long maintenance period.

- Q: How is glass made? What is its raw material?

- Glass is formed by the melting of sand with other chemicals. Glass raw materials for natural ore, the ore will be crushed first, processed into powder, according to the type of glass, according to the formula made of ingredients, into the glass furnace for melting, forming glass liquid. The glass passes through the feed tank and flows out of the feed port to form the stock. The temperature of the stock is 1150~1170 degrees centigrade and the alkali free glass is 1200~1220 degrees centigrade. The material shares every minute near '200 times cut into ball billet. The billet passes through the chute, the ball distributor and the ball plate, and then rolls into different funnels respectively, then falls into a groove formed by three rollers with the same rotating direction. When the ball is rotated on the roller and its surface tension, the ball glass is formed gradually. Its diameter is determined by the thickness, velocity, and shear velocity of the glass stream.

- Q: What is the raw material of glass glue?

- Mainly divided into two categories: neutral acid silicone rubber polyurethane adhesive can be indoor and outdoor weathering 107 RTV silicone rubber and calcium carbonate, silica, additives, mixing, vacuum glass glue chemical formula: 107RTV+SiO2+CaCO3= glass glue according to the technical requirements of the chemical equipment selection will differ.

- Q: Which brand of thermos cup is safe, double glass is not really glass, there is no other add, affect health?

- Double glass also called light industrial glass, raw materials for high boron silicon has a high heat resistance, the main production of glass teapot, coffee cup, cup, cup of hot water, there are many domestic manufacturers.

- Q: What's the difference between plexiglass PS boards and toughened glass? What's the difference between them?

- Suggest that you use semi tempered glass for bathroom glass, do not use non tempered, and the other two are not high prices, that is, shock resistance, heat resistance is not good, very crispThere is this, now you can choose several materials made of transparent or translucent, (the simplest is to take a rub, ha ha)

- Q: What's the difference between crystal and ordinary glass?

- To strike lightly or with fingers. Crystal glass can produce metal crisp sound, and waves a beautiful lingering in the air. We will see at the reception banquet, high-end glasses scenes in the movie, a kind of glass between the collision sound is. And high school, low grade crystal glass sound is also different. Like some low-end crystal glass or ordinary glass voice is relatively boring.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1996 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 101 - 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 60,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Silk Printing Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 20000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords