Silicone Impregnated High Temperature Resistance Silica Fiber Cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Silica fiberglass cloth is one high-temperature inorganic fiber with the molten temperature nearly 1700 degree Celsius, and the work for a long time at 900 degree Celsius.

Application:

Widely used as heat resistant and ablationresistasant material for rocket,missile and space vehicle;

High-temperature resistant,thermal insulation,refractory material;

Dust collect for high temperature gas;

Liquid filtration;Sound absorbing and thermal insulation for vehicle,motor bicycle;The thermal insulation protective materials for molten liquid filtration.

Product Capability:

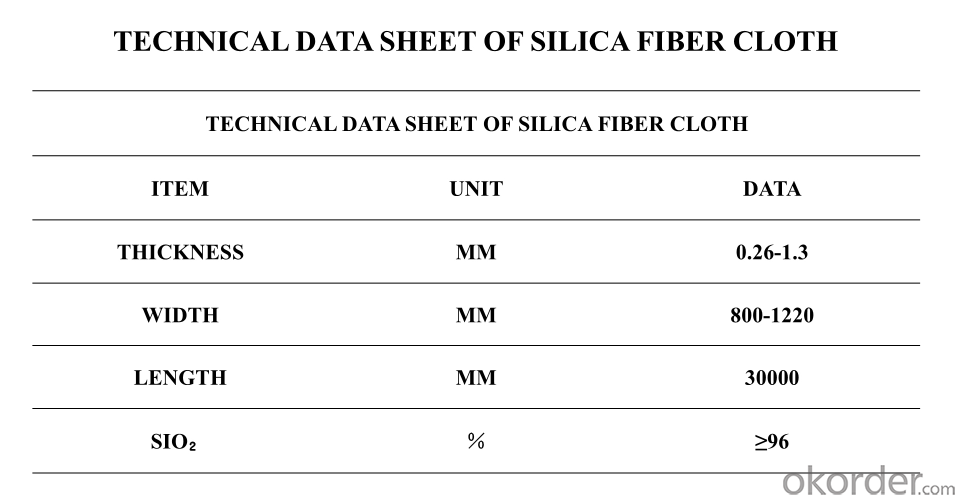

SiO2>=96%;

High temperature resistant,higher thermal insulation,low thermal conductivity;

Thermal stability and chemical stability;

High strength and easy to manufacture;

Nontoxic and harmless to the environment.

Data Sheet:

Fiberglass products:

Fiberglass is a kind of long fiber. It has the advantage of high tensile strength, low thermal conductivity, corrosion resistance and good insulation.The working temperature ranges from 200-1000 degree Celsius. Main products: Fiberglass texturized yarn, cloth, tape, rope, sleeve,mesh,filter cap,friction thread (piece) and fiber netting,composite yarn etc.

- Q: Can fiberglass fabric be used for making bags or backpacks?

- Yes, fiberglass fabric can be used for making bags or backpacks. Fiberglass fabric is known for its strength, durability, and resistance to tearing, which makes it an excellent choice for creating sturdy bags and backpacks. It is also lightweight, making it a suitable material for carrying items without adding excessive weight. Additionally, fiberglass fabric can be molded into various shapes and designs, allowing for customization and versatility in bag and backpack construction. However, it is important to note that fiberglass fabric is not flexible or soft like traditional fabric, so it may not be suitable for creating bags or backpacks that require a certain level of flexibility or softness.

- Q: What are the different colors available for fiberglass fabric rolls?

- Different needs and preferences can be accommodated with a variety of colors available for fiberglass fabric rolls. Commonly found colors include white, black, gray, yellow, green, blue, and red. These colors are achieved through the use of dyes or pigments during manufacturing. The choice of color for a fiberglass fabric roll depends on factors such as the intended application, aesthetic requirements, and visibility needs. For instance, white or light-colored fiberglass fabric rolls are often utilized in applications where visibility or reflectivity is crucial, such as safety clothing or high-visibility signage. Conversely, darker colors like black or gray may be favored for applications where aesthetics or light absorption play a significant role, such as theater backdrops or acoustic panels. Overall, the availability of various colors for fiberglass fabric rolls provides customization and versatility in numerous industries and applications.

- Q: Can fiberglass fabrics be used for sports or recreational equipment?

- Yes, fiberglass fabrics can be used for sports or recreational equipment. They are commonly used in the manufacturing of various sports equipment such as kayaks, canoes, surfboards, skis, and even hockey sticks. The high strength-to-weight ratio and durability of fiberglass fabrics make them an ideal choice for these applications, as they contribute to the overall performance and longevity of the equipment. Additionally, fiberglass fabrics can be molded into complex shapes, allowing for greater design flexibility in creating efficient and reliable sporting gear.

- Q: Can fiberglass fabrics be used for insulation in HVAC ductwork?

- Yes, fiberglass fabrics can be used for insulation in HVAC ductwork. Fiberglass is a commonly used material for thermal insulation due to its excellent heat resistance and insulation properties. It can help prevent heat loss or gain in ductwork, improving energy efficiency and maintaining desired temperatures. Additionally, fiberglass fabrics are lightweight, easy to install, and offer good acoustic insulation.

- Q: Can fiberglass fabric be used for insulation in aerospace structures?

- Indeed, fiberglass fabric proves to be a viable option for insulating aerospace structures. Possessing a lightweight and pliable nature, this material exhibits exceptional thermal insulation characteristics. By effectively capturing and minimizing heat transfer, it becomes an appropriate choice for safeguarding aerospace structures that necessitate precise temperature control. Moreover, fiberglass fabric's resistance to fire, chemicals, and moisture enhances its suitability for implementation in aerospace contexts. The material's optimal combination of strength-to-weight ratio and durability renders it an ideal selection for insulating diverse components within aerospace structures, including fuel tanks, engine compartments, and heating systems.

- Q: How does fiberglass fabric compare to other fabric materials in terms of cost?

- The cost of fiberglass fabric can vary depending on several factors, including quality, thickness, and how it is used. In general, fiberglass fabric is usually more expensive than traditional fabrics like cotton or polyester. However, when compared to specialized industrial fabrics like Kevlar or carbon fiber, fiberglass fabric often provides a more affordable option. The reason for fiberglass fabric's affordability is mainly because it is widely available and produced at a relatively low cost. Moreover, the durability and long lifespan of fiberglass fabric can lead to cost savings in the long term, as it may require fewer replacements or repairs compared to other fabric materials. Overall, although fiberglass fabric may not be the most inexpensive fabric option, it is often considered a cost-effective choice for various applications.

- Q: How does fiberglass fabric perform in high-temperature environments?

- Fiberglass fabric is known for its excellent performance in high-temperature environments. It is a type of fabric made from glass fibers that are woven together to create a strong and durable material. One of the main advantages of fiberglass fabric in high-temperature environments is its ability to withstand extreme heat. It has a high melting point, typically around 1470°C (2678°F), which makes it suitable for applications where temperatures can reach very high levels. In addition to its high melting point, fiberglass fabric also exhibits excellent thermal insulation properties. It has a low thermal conductivity, meaning it resists the transfer of heat. This makes it an ideal choice for applications where heat needs to be contained or insulated, such as in the construction of fire-resistant barriers or thermal insulation blankets. Furthermore, fiberglass fabric is highly resistant to fire and does not burn easily. It is non-combustible and does not contribute to the spread of flames, making it a safe choice for high-temperature environments where fire hazards are a concern. Another notable characteristic of fiberglass fabric is its dimensional stability under high temperatures. It maintains its shape and integrity even when exposed to extreme heat, which is crucial for applications where precise dimensions are required. Moreover, fiberglass fabric is resistant to many chemicals and corrosive substances, which further enhances its performance in high-temperature environments. It can withstand exposure to acids, alkalis, and solvents, ensuring its durability and longevity even in harsh conditions. Overall, fiberglass fabric is a reliable and versatile material that performs exceptionally well in high-temperature environments. Its ability to withstand extreme heat, provide thermal insulation, resist fire, and maintain dimensional stability makes it a preferred choice for a wide range of applications in industries such as aerospace, automotive, construction, and manufacturing.

- Q: How is fiberglass fabric different from other types of fabric?

- The composition and unique properties of fiberglass fabric set it apart from other types of fabric. Unlike natural fabrics like cotton or silk, fiberglass fabric is woven from thin strands of glass. This distinctive composition gives fiberglass fabric several advantages over other fabrics. First and foremost, fiberglass fabric is renowned for its exceptional strength and durability. The glass fibers used in its production are incredibly strong and resistant to tearing, stretching, and general wear and tear. This makes fiberglass fabric ideal for applications that require durability, such as in construction or industrial settings. Additionally, fiberglass fabric exhibits high heat resistance. The glass fibers used in its production have a high melting point, allowing the fabric to withstand extreme temperatures without deteriorating or catching fire. This makes fiberglass fabric suitable for use in applications where heat resistance is crucial, such as in fire-resistant clothing or insulation materials. Furthermore, fiberglass fabric boasts excellent chemical resistance. It is not easily affected by most chemicals, including acids, alkalis, and solvents. This makes fiberglass fabric a preferred choice in industries where exposure to corrosive substances is common, such as chemical processing or automotive manufacturing. Moreover, fiberglass fabric is known for its lightweight nature. Despite its strength and durability, fiberglass fabric is relatively light, making it easier to handle and transport compared to other heavy-duty fabrics. This lightweight property is particularly advantageous in applications where weight is a concern, such as in the aerospace or automotive industries. Lastly, fiberglass fabric possesses excellent insulation properties. It is a poor conductor of heat and electricity, making it an effective insulator. This insulation capability is beneficial in various applications, including thermal insulation for buildings, electrical insulation for wiring, or even the production of protective clothing for workers in extreme environments. In conclusion, fiberglass fabric's exceptional strength, heat resistance, chemical resistance, lightweight nature, and insulation properties make it stand out from other fabrics. Its unique composition and advantageous properties make it a versatile and preferred choice in various industries and applications.

- Q: Can fiberglass fabric be used for making molds?

- Yes, fiberglass fabric can be used for making molds. Fiberglass is a versatile material that is commonly used in the construction and manufacturing industries. It is known for its strength, durability, and ability to be molded into various shapes. When used for making molds, fiberglass fabric is typically layered with a resin or epoxy to create a rigid and durable structure. This combination allows for easy release of the molded object and provides a smooth finish. Fiberglass fabric can be used for a variety of mold-making applications, such as for creating prototypes, sculptures, or even industrial molds.

- Q: What are the different weaves available for fiberglass fabric?

- There are several different weaves available for fiberglass fabric, each with its own unique characteristics and uses. Some of the most common weaves include plain weave, twill weave, satin weave, and leno weave. Plain weave is the simplest and most common weave used for fiberglass fabric. It is characterized by an equal number of warp and weft yarns crossing over and under each other in a simple over-under pattern. This weave creates a strong and balanced fabric with good stability and durability. Twill weave is another popular option for fiberglass fabric. In this weave, the warp and weft yarns cross over and under each other in a diagonal pattern, creating a distinctive diagonal ribbing effect. Twill weave provides better drapability and flexibility compared to plain weave, making it suitable for applications that require greater conformability. Satin weave is a more complex weave that produces a smooth and shiny surface on the fabric. It is characterized by long floats of the warp or weft yarns, which means that fewer yarns are interlaced, resulting in a more flexible and lightweight fabric. Satin weave is often used in applications where a high-quality appearance and a soft feel are desired, such as in the production of clothing or decorative fabrics. Leno weave is a unique weave that involves twisting adjacent warp yarns around each other to create a stable and open mesh structure. This weave is commonly used for fiberglass fabrics that require high transparency and breathability, as well as for applications that involve filtration or reinforcement purposes. Overall, the choice of weave for fiberglass fabric depends on the specific requirements of the application. By considering factors such as strength, flexibility, appearance, and breathability, one can select the most suitable weave to achieve optimal performance in their desired application.

Send your message to us

Silicone Impregnated High Temperature Resistance Silica Fiber Cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords