Ductile Iron Casting Silicon Carbide Ceramic Filter Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Ceramic Foam Filter :

Silicon carbide ceramic foam filters are mainly designed to improve the quality of iron castings. The filter can effectively remove non-metallic inclusions slag and dross from the molten metal stream.

2.Main features of Ceramic Foam Filter:

◆ Excellent thermal shock resistance

◆ Good strength under high temperature

◆ Improving casting quality

◆ Reducing turbulence in gating system

◆ Tailored sizes as customers requirement

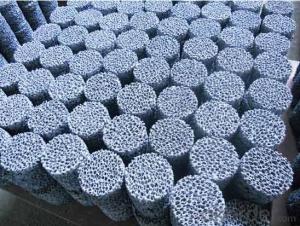

3. Ceramic Foam Filter Images:

4. Ceramic Foam Filter Technical Parameters

There are four kinds of ceramic foam filter according to different usages.

They are Silicon Carbide Ceramic Foam Filter, Zirconia Ceramic Foam Filter, Alumina Ceramic Foam Filter, Magnesia Ceramic Foam Filters.

Application

Grey iron casting, ductile iron casting, precious metals casting

Copper casting, bronze casting, brass casting

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our ceramic fiber products?

A world class manufacturer & supplier of ceramic fiber product is one

of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 80000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How many degrees does the ceramic filter melt?

- Alumina made from tabular corundum can be used over 1800 degrees!SiC if there is atmosphere, protection will be higher, there is no atmosphere protection, because the existence of oxidation, generally not more than 1600.Corundum, mullite, 1750 degrees small meaning.

- Q: What are the causes of the powder moisture in the ceramic filter?

- Generally, the ceramic filter is used to filter iron powder, and the water content of the filter cake is about 10%.

- Q: Can the plate filter press pass through the filter plate?

- There are many types of pumps to be used, such as screw pumps, slag pumps, rotary pumps, piston pumps, and diaphragm pumps.

- Q: Ceramic filter fineness thin mud suction is not what to do more

- Users such as pulp size is too small, too much mud, after analysis, the following methods of testing, the results have improved, it may wish to try the following methods, perhaps of help:The vacuum degree is about -0.08MPa.Adjust spindle speed and increase drying time.Ceramic filter plate with suitable pore size range.Ceramic filter plate brand on the market range, its quality is good or bad, the feed condition itself is not an ideal situation, such as ceramic filter plate with the aperture to the mine conditions do not match, it will exacerbate the effects of poor, life is short.It can shorten the combined cleaning cycle, strengthen the cleaning effect and prolong the cleaning time.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- The concentration, particle size and mud content of the raw materials are not suitable for or due to changes, which are no longer suitable for dehydration using ceramic filters

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large?

- The vacuum degree of the ceramic filter is normal at about -0.08MPa. Under normal circumstances, the water content of the filter cake treated with a ceramic filter is about 10%, and the moisture content of the tail filter cake is about 15%. The water content of the filter cake increases with the increase of water content in the ceramic filter.

- Q: What's the acid of the ceramic filter plate?

- General ceramic filter running for eight hours or so, you need to stop for joint cleaning, general cleaning at an hour or so. When washing together, there is acid washing, usually concentrated nitric acid. The purpose is to dissolve the pores in the ceramic filter plate through nitric acid.

- Q: What are the functions of honeycomb ceramic filters?

- High quality and high density straight hole mesh, the product has high heat resistance and impact resistance properties of cast high fever temperature, design straight hole to guarantee the balance between strength and flow, effectively remove impurities and slag particles, the mechanical properties of casting, the surface quality and the qualified rate of products is greatly improved.

- Q: What are the reasons for the program alarm of ceramic filter?

- The vacuum failure may be the vacuum pump failure, the vacuum pipeline leakage, the ceramic filter plate rupture or the connection water leakage, the backwash system is generally before the filtration water pressure is insufficient, the filter core plug and so on. Vacuum suction deficiency will lead to poor effect or even suction; cleaning standards will accelerate the ceramic filter clogging, ceramic filter clogging even if the vacuum suction is normal, will not even bad effect such as cake, jelly thin with high water content. Ceramic filter plate, hole plugging, discarding. Ceramic filter plate is life, under normal circumstances is about a year, such as pulp mud content, fine particle size or containing ingredients, cleaning is not easy to precipitate standards will reduce its life, when the ceramic filter plate close to the scrap, the suction effect will be worse. I hope my answer can help you.

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber board quality can be judged from the following aspects:1, appearance. The surface is flat and the cutting surface is well arranged, and vice versa.2 density. Press the hands, and the surface is soft and smooth.3, process. Vacuum suction and continuous production process.4, cross section, slag ball content is low.

Send your message to us

Ductile Iron Casting Silicon Carbide Ceramic Filter Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords