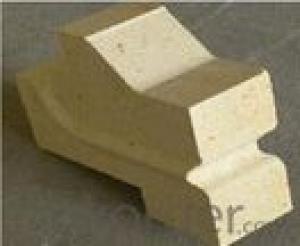

Silica Brick for High Duty Hot Air Stove

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 pallet

- Supply Capability:

- 30000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

The silica brick can be widely used in coke oven, hot blast furnace, glass furnace and carbon furnace. In glass industry, it is mainly employed to build the doghouse crown, suspended wall of channel, top crown and inlet sealing. In metallurgy industry, it is adopted as the nozzle brick

Features

1.High purity

2.Long service life

3.Accurate size tolerance

4.Pure color

5. Luster appearance

6..Good thermal conductivity

7.Good creep resistance

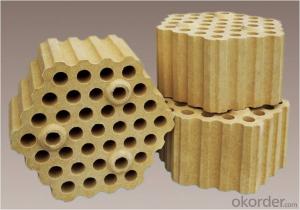

Application of the refractory silica bricks

Glass melting tank

Glass furnace

Hot-Blast Stoves

Hot Air Stoves

Physical & chemical indexes of the refractory silica bricks

General silica brick:Siliceous refractory products used for various large coke oven, glass kiln stove, hot air stove, etc. | |||

Item | GZ-96 | GZ-95 | GZ-94 |

SiO2 % ≥ | 96 | 95 | 94 |

Fe2O3 % ≤ | 1 | 1.2 | 1.4 |

Refractoriness °C≥ | 1710 | 1710 | 1690 |

Apparent porosity % ≤ | 22 | 22 | 24 |

Cold crushing strength Mpa ≥ | 29.4 | 24.5 | 19.6 |

Refractoriness under load, 0.2MPa, °C≥ | 1660 | 1650 | 1640 |

True density g/cm3 ≤ | 2.34 | 2.35 | 2.35 |

- Q: Common bond brick?

- When adding ingredients, the amount of lime added shall be converted to CaO, and the amount of addition varies depending on the product, usually fluctuating at 1.5~2.5%. For example, the production of coke oven silica brick, the dosage of CaO is 2.0~3.0%; the production of electric furnace top brick, the dosage of CaO is 1.4~1.75%.

- Q: The introduction of silica brick

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: Semisilica brick interpretation

- Good thermal shock resistance. In use, more high viscosity glass phase can be formed, and the masonry brick joint and the working surface are dense and the masonry is complete, which is beneficial to improve the impermeability of the masonry and reduce the erosion effect of the slag on the masonry.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The high thermal conductivity of silica brick all inherits the advantages of traditional coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity.

- Q: How much is the highest melting point of silicon?

- Mainly used for partition, carbonization chamber of coke oven and combustion chamber open hearth furnace regenerator and a sediment chamber, soaking furnace, glass melting furnace refractories and ceramic kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- The scale quartz is a spear shaped double crystal structure, very compact and favorable to the increase of thermal conductivity. The high thermal conductivity of silica brick in improving thermal conductivity and other performance indicators and traditional coke silicabrick agreement.That is to say, the high thermal conductivity of silica brick all inherited the traditional advantages of coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity

- Q: Common bond brick?

- When adding ingredients, the amount of lime added shall be converted to CaO, and the amount of addition varies depending on the product, usually fluctuating at 1.5~2.5%. For example, the production of coke oven silica brick, the dosage of CaO is 2.0~3.0%; the production of electric furnace top brick, the dosage of CaO is 1.4~1.75%.

- Q: Brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on.

- Q: The chemical composition of silica brick and its physicochemical index?

- The physicochemical index of silica brick:Turn left to |

- Q: What is the silica refractory products?

- High silicon content in high temperature expansion sintering temperature between 1390-1410 in furnace arch

Send your message to us

Silica Brick for High Duty Hot Air Stove

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 pallet

- Supply Capability:

- 30000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords