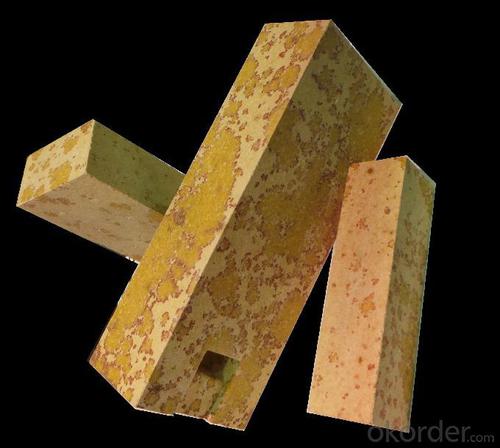

Alumina Silica Brick Super Duty Silica Brick for Glass Melting Tank 93

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

The CMAX super-duty silica bricks for glass melting tank is characterized by high purity, less impurity, good corrosion resistance, higher bulk density, complete phase transformation, lower residual quartz, high RUL, lower thermal expansion and stable volume at high temperature. This leads to increase in service life of glass furnace and reduction in energy consumption. These products have found wide application in crown and key areas and been highly appreciated by clients.

Feature

CMAX Silica bricks produced by CNBM are characterized by smaller density, good thermal shock resistance, lower thermal conductivity, high RUL and good insulating performance.

Application

Glass melting tank

Glass furnace

Physical Properties and Chemical Compositions

Item | Values |

SiO2 % | ≥93 |

Bulk density g/cm3 | ≥1.0 |

Cold crushing strength MPa | ≥2.0 |

Permanent linear change % 1450℃,2h | ≤0.5 |

Refractoriness under load 0.2MPa °C | ≥1500 |

Thermal conductivity W/(m.k) (350±10°C on the average) | ≤0.55 |

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: Semisilica brick interpretation

- High temperature volume stability. Volume change is small.

- Q: What is acid refractory?

- Refractory materials are mainly quartz glass products, combined with fused quartz products, silica brick and unshaped refractories. Semi siliceous refractory materials are generally attributed to this category. As for fireclay refractories, they are also classified as semi acidic or weakly acidic refractories. Also, zircon refractory and silicon carbide refractory for special acidic refractory materials are also classified into this category.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: Common bond brick?

- When adding ingredients, the amount of lime added shall be converted to CaO, and the amount of addition varies depending on the product, usually fluctuating at 1.5~2.5%. For example, the production of coke oven silica brick, the dosage of CaO is 2.0~3.0%; the production of electric furnace top brick, the dosage of CaO is 1.4~1.75%.

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- To improve the thermal conductivity of silica brick for coke oven rate method:Manufacture of high density and high thermal conductivity of silica brick, adding additives such as CuO, Cu2O, TiO2, Fe2O3, (FeO), can improve the thermal conductivity of silica brick.

- Q: The chemical composition of silica brick and its physicochemical index?

- Brick refers to the refractory products in more than 93% of the content of SiO2

- Q: High temperature refractory material?

- Basic refractories in Magnesium Oxide and calcium oxide as the main component, the main products are magnesia brick, magnesia chrome brick, magnesia zirconia brick, magnesia brick, magnesia spinel brick, magnesia calcium brick, dolomite brick and the latest development of magnesia spinel brick and so on. With Magnesium Oxide (MgO) more than 80% of the refractory brick called magnesia brick,

- Q: The formula in the refractory brick, and firing curve, who knows?

- By silica powder, 81-85%, perlite 15-19%, plus the total weight of the main raw materials of the following accessories

Send your message to us

Alumina Silica Brick Super Duty Silica Brick for Glass Melting Tank 93

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords