Silica Brick for Coke Oven Cmax-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Item | Speification | ||

| ASC-1 | ASC-2 | ASC-3 | |

| Al2O3 and MgO | ≥58 | Al2O3 and SiC≥80 | ≥68 |

| SiC | ≥10 | ≥10 | |

| C | ≥6 | ≥8 | ≥10 |

| Apparent porosity(%) | ≤10 | ≤10 | ≤10 |

| Bulk density(g/cm3) | ≥2.65 | ≥2.85 | ≥2.98 |

| Cold crushing strength(MPa) | ≥35 | ≥50 | ≥35 |

| Modulus of rupture at room temperature | ≥2 | ≥4 | ≥2 |

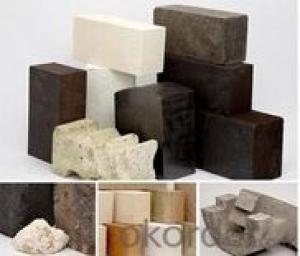

Alumina silicon carbide carbon brick using grade alumina, fused alumina, silicon carbide, graphite and high-pressure molding of additives, mainly for ordinary ladle, ladle desulfurization, Large torpedo car.

Alumina silicon carbide carbon brick as a composite refractories, Effective use of the high thermal capacity and strong resistance to slag erosion and magnesia carbon, low expansion, the biggest drawback is compensated magnesia poor chipping resistance.

Specifications

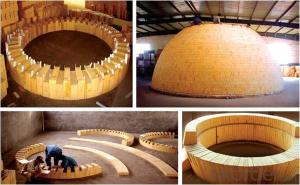

SILICA BRICK FOR COKE OVEN

1. NASDAQ listed company

2.stock code: ANNC

3. many patent products

4.pass ISO,GB,YB,DIN

- Q: Physical solid waste disposal

- The production of silicon material is added to the cause of waste brick:Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products during firing

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- How to keep the brick masonry temperature not lower than 600 DEG C, while the exhaust temperature is not higher than 400 DEG C.

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- Small fluctuations in the chemical composition do not have a significant effect on use. The key is the operation of the electrolyzer in production to determine whether the side wall will be damaged.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Brick bearing soft temperature and close to the melting point, high temperature strength, can be in high temperature (above 1400 degrees) under the condition of long-term use,

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q: Can iron oxide be used as refractory material?

- Is widely used in this area. Mentioned refractory material of high school textbooks generally refers to three two aluminum oxide (alumina), alumina is also used as a refractory material, refractory crucible, porcelain, artificial gemstones.

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: Brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on.

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

- Q: High temperature refractory material?

- Special materials often use AZS brick (i.e. corundum brick), corundum brick, magnesia chrome bricks, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Insulation refractories are often used diatomite products, asbestos products, insulation board. Unshaped refractories are often used refractory castable, refractory clay, refractory ramming material, refractory plastic and fettling material, fire resistance, gunning, refractory cast material, fireproof coating, lightweight refractory castable, gun mud.

Send your message to us

Silica Brick for Coke Oven Cmax-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords