Graphite Crucible for Sale Near Me - SIC Crucibles for Melting Aluminium, Copper, and Brass with High Heat Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for SiC Graphite Crucibles

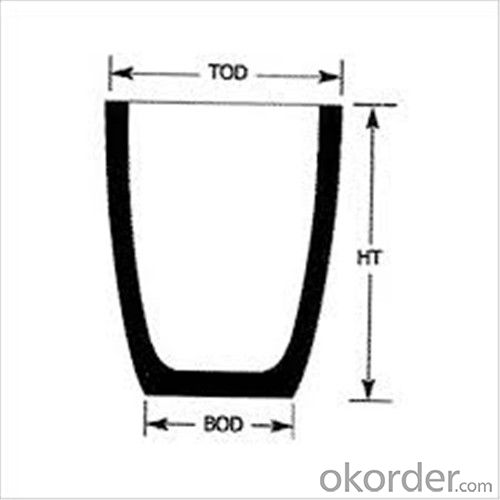

| Type: | High Strength, graphite crucible crucible | Application: | melting metal | Height: | as your requirements |

| Composition: | High Pure | Top Diameter: | 10-600mm | Bottom Diameter: | 10-1000mm |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | ||

| Color: | Black grey | Si3N4%: | 5min | Fe2O3%: | 0.7max |

| C%: | 30-45 | Apparent porosity: | 30max | Refractoriness: | 1680 |

| Bulk Density: | 1.71min | Using life: | >5000 hours | MAX temperature: | 1600c |

Packaging & Delivery

| Packaging Details: | Seaworty packing or as per customer's detail requirement of graphite crucible. |

| Delivery Detail: | within 20-30 days after confirm order of graphite cru |

SiC Graphite Crucibles For Melting Aluminium And Copper, Brass

Product Description

Specifications for Graphite Silicon Carbide Crucible For Aluminum Melting :

1.Long working lifetime: its working lifetime is increased 3-5 times over normal clay-crucible due to the compact body formed under high pressure.

2.High thermal conductivity: high-density body and low apparent porosity greatly improve its heat conductivity.

3.New-style materials: new heat conduction material ensures faster heat conductivity and pollution-free product, reduces adherent slag.

4.Resistance to corrosion:better anti-corrosion than normal clay-crucible.

5.Resistance to oxidation: advanced process dramatically improves its oxidation resistance, which ensures persistent heat conductivity and long working lifetime.

6.High-strength: high-density body and logical structure make the product better compression property.

7.Eco-friendly: energy-efficient and pollution-free, not only ensure metal product purity, but also ensure sustainable development on environment.

8.Multi-function: Can be used in induction graphite crucible furnace

Features of SiC 95% silicon carbide sic crucible

1. resistance to deformation at high temperature,

2. thermal shock resistance, wear resistance, corrosion resistance.

3. anti-oxidation, anti- erosion.

Usage of SiC 95% silicon carbide sic crucible

electricity and steel slag trench,

coal chemical and mining transport pipeline.

- Q: Why are there too many impurities in the gravity casting products of aluminum alloy, so they can not be welded well by argon arc welding?

- The official must before casting of aluminum liquid refining slag and gas, because the melting use graphite crucible furnace or silicon carbide crucible furnace refining, so do not suggest that the addition of a solvent in order to avoid corrosion of crucible, the best refining slag degassing process is the use of rotary degassing machine by introducing inert gas such as nitrogen and argon (the best), impurity and hydrogen in liquid aluminum removal, complete slag removal and gas to test the effect of slag by K model, and use the detection instrument for measuring hydrogen hydrogen content, to meet the requirements after the investment casting used.

- Q: Can graphite crucibles be used for metal powder atomization?

- Yes, graphite crucibles can be used for metal powder atomization. Graphite crucibles are often preferred for their high melting point, excellent thermal conductivity, and chemical resistance. These properties make them suitable for the high-temperature process of metal powder atomization, where fine metal powders are produced by rapidly cooling molten metal. Additionally, graphite crucibles provide good control over the atomization process, making them a popular choice in industries such as aerospace, automotive, and additive manufacturing.

- Q: Can a graphite crucible be used for melting steel?

- No, a graphite crucible cannot be used for melting steel. Graphite crucibles are typically used for melting non-ferrous metals such as gold, silver, and aluminum. Steel requires a crucible made of materials with higher melting points, such as clay-graphite or silicon carbide.

- Q: What are the different methods of preventing cracks in a graphite crucible?

- To prevent cracks in a graphite crucible, there are several effective methods that can be utilized: 1. Employing preheating: Prior to use, it is beneficial to preheat the graphite crucible. This can be achieved by gradually increasing the temperature to the desired operating level. This gradual heating allows for uniform expansion of the graphite, thus reducing the possibility of thermal shock and subsequent cracking. 2. Implementing gradual cooling: After use, it is crucial to cool the crucible in a gradual manner. Abrupt changes in temperature can result in thermal stress and ultimately lead to cracks. By allowing the crucible to cool slowly, the risk of such stress is minimized. 3. Avoiding sudden temperature fluctuations: It is imperative to utilize the graphite crucible in a controlled manner, avoiding rapid temperature changes. Swift heating or cooling can induce thermal shock and increase the likelihood of cracking. Thus, maintaining a consistent temperature during both the heating and cooling processes is of utmost importance. 4. Exercising proper handling techniques: The careful handling of the crucible is vital in the prevention of cracks. Any instances of dropping or forcefully impacting the crucible against hard surfaces should be avoided, as this can result in physical damage and weaken the graphite structure. 5. Applying protective coatings: An additional layer of insulation and prevention of direct contact between the molten material and the graphite can be achieved by employing a protective coating on the inner surface of the crucible. This coating serves to reduce chemical reactions and thermal stress, thereby diminishing the risk of cracks. 6. Engaging in regular maintenance and inspection: Consistently inspecting the crucible for any indications of wear, damage, or cracks is indispensable. Identifying potential issues at an early stage can prevent further harm and ensure the longevity of the crucible. Through the implementation of these methods, the risk of cracks in a graphite crucible can be minimized. This ensures the crucible's durability and effectiveness in various high-temperature applications.

- Q: Can graphite crucibles be used for alloy preparation?

- Yes, graphite crucibles can be used for alloy preparation. Graphite is a suitable material for crucibles due to its high melting point, excellent thermal conductivity, and chemical inertness. It can withstand high temperatures and is commonly used in metallurgical processes for smelting and alloying different metals.

- Q: Does a graphite crucible react with any substances during use?

- No, a graphite crucible does not react with any substances during use. Graphite is chemically inert and has a high melting point, making it ideal for use in high-temperature applications such as melting metals. It does not react with the materials being melted or with any other substances present in the crucible. This property of graphite allows for the safe and efficient handling of various substances during processes such as metal casting, melting glass, or performing chemical reactions.

- Q: Is pig iron smelted in a graphite crucible?

- The iron obtained directly from ore smelting is called pig iron. As the iron ore, coke, limestone and so on are mixed together, the molten iron is in direct contact with coke, slag, etc., and carbon, sulfur and other elements in the coke will seep into the molten iron. At the same time, the chemical gas in the furnace gas will react with the iron, and the products will also be mixed into the molten iron. Therefore, the impurity content in pig iron is higher, and the main impurities are five basic elements, such as carbon, silicon, manganese, sulfur and phosphorus, as well as some non-metallic inclusions.

- Q: What are the technical specifications of graphite crucibles?

- Crucible; physical and chemical index; standard parameter; test dataThe refractoriness is 1680 degrees, and the refractoriness is 1685Carbon content 38%, carbon content 41.46%Porosity less than 35% porosity is less than 32%Volume density 1.6g/cm3 volume density 1.71g/cm3The above data are referred to Qingdao Huatai graphite, hope to adopt, thank you.

- Q: Can graphite crucibles be used for carbon fiber production?

- Carbon fiber production can utilize graphite crucibles, which are often employed in high-temperature situations due to their exceptional thermal conductivity, high melting point, and chemical resistance. To create carbon fiber, graphite crucibles can be utilized to heat and liquefy the precursor materials like polyacrylonitrile (PAN) or pitch. These materials then undergo a series of steps to generate carbon fiber. Graphite, known for its high-temperature stability and lack of reactivity, serves as an ideal substance for maintaining the necessary conditions during the carbonization process. Furthermore, the smooth surface of graphite crucibles plays a significant role in achieving uniform heat distribution, an essential factor in ensuring the quality and consistency of carbon fiber production. As a result, graphite crucibles prove to be a suitable choice for the production of carbon fiber.

- Q: What are the different methods of preventing contamination from graphite dust?

- To prevent contamination from graphite dust, there are several approaches that can be utilized. 1. Ventilation Systems: It is crucial to install appropriate ventilation systems in areas where graphite dust is produced. These systems play a vital role in capturing and eliminating dust particles from the air, thereby reducing the risk of inhalation or settling on surfaces. 2. Enclosures and Barriers: Creating physical barriers and enclosures around areas where graphite dust is generated can effectively contain the particles within a controlled space. This containment prevents the dust from spreading to other parts of the facility or affecting nearby equipment. 3. Personal Protective Equipment (PPE): Workers who are exposed to graphite dust should wear suitable PPE to minimize contamination. This may include respiratory masks or respirators, goggles, gloves, and protective clothing to prevent direct contact with the dust. 4. Regular Cleaning and Maintenance: Strict adherence to a cleaning and maintenance schedule is essential in preventing the accumulation and spread of graphite dust. Surfaces, equipment, and machinery should be regularly cleaned using methods that minimize dust dispersion, such as wet cleaning or vacuuming with HEPA filters. 5. Process Modification: Altering the production process can also be effective in preventing graphite dust contamination. Implementing measures like wet cutting or machining instead of dry processes significantly reduces the generation and spread of dust particles. 6. Training and Awareness: Educating workers about the hazards of graphite dust and providing training on proper handling, cleaning, and maintenance procedures are crucial in preventing contamination. Workers should be informed about the risks associated with graphite dust exposure and equipped with the knowledge to take necessary precautions. By employing a combination of these methods, facilities can successfully prevent contamination from graphite dust and ensure a safe and healthy working environment.

Send your message to us

Graphite Crucible for Sale Near Me - SIC Crucibles for Melting Aluminium, Copper, and Brass with High Heat Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords