Clay Graphite Foundry Crucible - Jewellery Induction Casting Crucible Galloni CG40(500), Graphite Melting Crucible

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 10000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Detailed Product Description

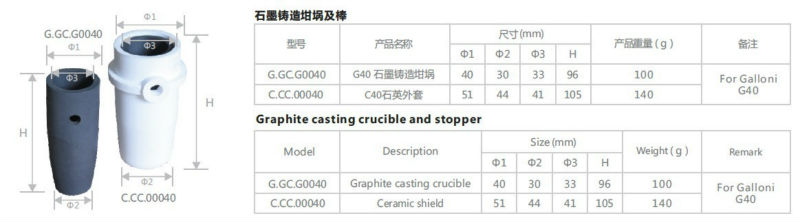

Jewellery Casting crucible CG-40 induction casting machine. Crucible capacity 500 G

- Q: What are the carbon elements? What are their structures? What are their properties and uses?

- Graphite, diamond, fullerene (C60) in recent years, scientists have found that in addition to diamond, graphite, and some new existence in the form of element carbon. The earlier found and has made important progress in the study of the C60 molecule.

- Q: Can graphite crucibles be used for melting explosives?

- High temperature applications, like melting metals, often employ graphite crucibles. However, caution must be exercised as these crucibles are not suitable for melting explosives. Graphite possesses excellent heat conductivity, facilitating rapid attainment of high temperatures. Nonetheless, it can react with specific chemicals, including explosives, causing unforeseen reactions, safety risks, and potential damage to the crucible. Hence, it is imperative to employ specialized materials and equipment exclusively crafted for melting explosives, guaranteeing the safety of the process and individuals involved.

- Q: What are the main components of a graphite crucible?

- The main material of graphite crucible is crystalline natural graphite, so it has good heat transfer and high temperature resistance. It has strong corrosion resistance to acid and alkaline solution, and has excellent chemical stability. There are many types of graphite crucibles, which are limited in application and can be chosen at will. Based on the above properties, the graphite crucible is widely used in metallurgy, casting, machinery, chemical and other industrial sectors.

- Q: What are the common sizes available for graphite crucibles?

- The common sizes available for graphite crucibles range from small ones that can hold a few grams of material to larger ones that can hold several kilograms.

- Q: Rotary kiln dust removal, zinc coated sand and Zinc Oxide Technology

- Using a simple stove, will prepare zinc into Zinc Oxide: Zinc in graphite crucible, with coke heating outside heated zinc sublimation after reaction with oxygen to generate Zinc Oxide in the air above a collection system using tinplate can collect content of more than 99% Zinc Oxide.

- Q: Can a graphite crucible be used for heat exchanger applications?

- Using a graphite crucible for heat exchanger applications is not possible. A crucible serves as a container for holding and melting materials at high temperatures, typically used in laboratories or industrial settings. Its purpose is to endure extreme heat and chemical reactions, but it is not designed for efficient heat transfer. In contrast, a heat exchanger is a device explicitly created for transferring heat between two fluids or between a solid surface and a fluid. It is constructed with specific materials and structures to optimize heat transfer efficiency. Graphite, despite its good thermal conductivity, is not an ideal material for heat exchangers due to its limitations in mechanical strength, pressure resistance, and corrosion resistance. Therefore, it is advisable to utilize materials specifically designed for heat exchanger applications, such as metals like copper, stainless steel, or titanium. These metals possess superior thermal conductivity and can withstand the high pressures and corrosive environments that are often encountered in heat exchanger operations.

- Q: Can graphite crucibles be used for melting reactive metals?

- Yes, graphite crucibles can be used for melting reactive metals. Graphite is highly resistant to heat and has excellent thermal conductivity, making it an ideal material for high-temperature applications such as melting reactive metals. Additionally, graphite is chemically inert and does not react with most metals, including many reactive ones. However, it is important to note that there are certain reactive metals, such as alkali metals or certain rare earth metals, that can react with graphite at high temperatures. In such cases, alternative crucible materials like refractory metals or ceramics may be more suitable.

- Q: How long can a graphite crucible last?

- The lifespan of a graphite crucible can vary depending on several factors such as usage, temperature, and handling. Generally, a well-maintained graphite crucible can last for several months to a few years, with regular inspections and proper care.

- Q: Is pig iron smelted in a graphite crucible?

- The ironmaking raw materials with iron ore (Fe2O3), smelting iron ore, coke (fuel), limestone (solvent) and charge together into the blast furnace, under certain temperature and pressure, through a series of chemical reactions, the reduction of iron ore.

- Q: I'd like to smelt 104 aluminium alloy by medium frequency furnace. What should I pay attention to? Please point it out, thank you!

- Don't know what is your crucible material medium frequency furnace, if using graphite crucible, graphite as easily broken and easy to absorb moisture, must be handled with care to avoid the collision, but must be in use before the slow heating and drying, until the crucible to dark red, check no cracks can be put into the molten alloy. If the iron crucible, the Aluminum Alloy are strictly limited, so the iron, iron crucible, Tieshao, ladle, the tool must be coated with paint, paint is selling goods, components do not know, iron crucible and apparatus must also be preheated, exclusion of moisture. In addition, do not know you are refining aluminum ingot or making ah Aluminum Alloy parts, if the production parts should pay attention to defects of oxidation, slag and coarse grain, I am afraid that refining, refining agent are also ready to sell goods, how can read the instructions. Especially when smelting Caution!, preventing aluminum liquid splash, including many contents, such as inspection and testing, there is not much to say, the main note in the smelting process I thought so much, typing is slow, very hard ah, hey. Hope to be of some help to you.

We are always keeping enlarging production scale, perfecting management system, and improving office facilities to expand our markets both at home and abroad.We sincerely welcome clients at home and abroad to come for negotiations.

1. Manufacturer Overview

| Location | Guangdong,China (Mainland) |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Clay Graphite Foundry Crucible - Jewellery Induction Casting Crucible Galloni CG40(500), Graphite Melting Crucible

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 10000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords