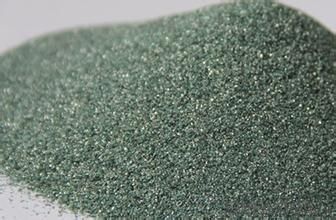

SIC Black and Green Silicon Carbide Carborundum - Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Black Silicon Carbide Carborundum

The Chemical Formula of Silicon Carbide, which is also known carborundum, is SiC. It is produced by the carbothermal reduction of silica to form an ultra-hard covalently bonded material.

Black Silicon Carbide (C)

It is used to grind cast iron, on-ferrous metals, rubber, leather, lactic, wood, mineral rocks, etc. It can also be used to manufacture high-class refractory products.

Grit | SiC | F.C. | Fe2O3 |

F12-F90 | 98.50%min | 0.20%max | 0.60%max |

F100-F150 | 98.00%min | 0.30%max | 0.80%max |

F180-F220 | 97.00%min | 0.30%max | 1.20%max |

F230-F400 | 96.00%min | 0.40%max | 1.20%max |

F500-F800 | 95.00%min | 0.40%max | 1.20%max |

F1000-F1200 | 93.00%min | 0.50%max | 1.20%max |

P12-P90 | 98.50%min | 0.20%max | 0.60%max |

P100-P150 | 98.00%min | 0.30%max | 0.80%max |

P180-P220 | 97.00%min | 0.30%max | 1.20%max |

P230-P500 | 96.00%min | 0.40%max | 1.20%max |

P600-P15000 | 95.00%min | 0.30%max | 1.20%max |

P2000-P2500 | 93.00%min | 0.50%max | 1.20%max |

0-1mm,1-3mm,3-6mm | 95.00% | 0.30%max | 1.20%max |

- Q: A chemical problem with refractory materials

- In chemistry, there is never absolute

- Q: Refractory materials are needed for casting metallurgy.

- Refractory material used in foundry work is that refractories for cupola furnace? Cupola is a high temperature furnace which is used for melting molten iron, and refractory material adopted is mainly low iron high grade clay brick and clay lightweight insulation bricks, etc.foundry ingot refractory material is pearl sand (also known as pearl jewelry sand, fused ceramic, ceramic sand) it is made of high quality bauxite material by arc melting furnace.

- Q: Which are fire proofing thermal insulation materials?

- aluminum silicate fiber, ceramic fiber, etc,

- Q: Is there requirement for radiation indicator in refractory?

- All refractories have no radiated harm to environment, so there is no requirement. From the elemental analysis, magnesite. I do not know it is helpful to you. But for refractory rwa material, any chemical element is radiated, including silicon?dioxide; If they are radioactive. From the use analysis, such as bauxite, do not have use value.

- Q: Does the refractory material used in steelmaking all refer to refractory brick?

- It includes not only refractory brick but also unshaped refractory; while the foaming?agent, ladle filler sand and deoxidizer are not refractory materials but ferrous metallurgy auxiliary materials.

- Q: How long is the fire endurance of the rock wool board?

- In the fire?safety?rules, of the building materials are classified as non-burning combustion body, difficult to burn the body and burning body categories depending on its difficulty level of burning. Rock wool board is the fiber processed by the coated steel sheet and basalt minerals and other inorganic minerals,and the building panels through artificial composition. Because that the dominant sectors, like, steel plate and rock wool are non-combustible materials, so it should be considered as non-combustible?component. The fire resistance of rock wool board has its judging criteria. Loss of support capacity, loss of integrity and loss fire insulation function. Its fire resistance is within 2 hours.

- Q: What do refractory materials include?

- It is so difficult.

- Q: What are the material requirements of class A fire resistant door ?

- What are the material requirements of class A fire resistant door ?

- Q: Who knows the fire endurance of rock wool color plate?

- I'm glad to answer your question and offer you some of my experiences, for reference only. In fire?safety?rules, it can be divided into non-combustible component, hard-combustible component, combustible component according to the combustible degree of building materials. Rock wool board is building board recombinated artificially by fibers processed by coated steels and inorganic minerals like basalt mineral, because steel plate and rock wool which is the main components are non-combustible material, so rock wool board should be considered as non-combustible component. The fire endurance of rock wool board has its own judging criteria. Lose sustaining power, integrity and fire insulation function. Its fire endurance is within 2 hours.

- Q: what's the materials of fireproof?housing?

- I'm very glad to answer for you. 1. Mobile homes in high-rise buildings, as for the interior hidden artifacts of single and multi-layer mobile homes, when its fire endurance is ruled above 1.5 h, you should choose the non-swelling large activity fire?retardant?coating; 2.as for Indoor mobile house, light roof mobile house and mobile house need to be decorated, when its fireproof limit is ruled under 1.5 h, you can choose swelling mobile house fire?retardant?coating; 3. The fire endurance of mobile houses need to be above 1.5 h, outdoor mobile houses project shoule better not choose swelling fire?retardant?coating. 4. Indoor mobile houses extremly need to be decorated, hot standby is a living place of mobile houses, bearing steel structure of equipment, bracket, the part easy to be knocked like skirt, its fire endurance needs to be above 1.5 h, you better choose fireproof?panel of mobile houses. 5. Open mobile houses, you should choose fire?retardant?coating of mobile houses suitable for outdoor, and use the coating with over one-year outdoor mobile houses project operation and the coating function without significant changes. 6. multiple layer coating should be matched with each other, the bottom layer coating should be able to be used with rust-proof paint together or have rust-proof function. 7, while choosing the fire?retardant?coating for special function, it should have over one-year project operation and verification case and matched fire-proof function.

Send your message to us

SIC Black and Green Silicon Carbide Carborundum - Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords