M200 Geotextile - Geotextile Polyester Non-Woven Fabric for Construction and Roadbed Paving

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) Function: Separation, filtration, reinforcement, drainage

2) Usage:

Separation of different materials.

It is widely applied between subgrade and groundwork of the paved (unpaved) road or airport road.

applied between the subgrade and ballast of the railway,

applied in the landfill ground and gravel subgrade,

applied between the geomembrane and sandy drainage layer,

applied between the subgrade and groundwork to undertake the additional load.

applied between the earth of groundwork and foundation soil,applied under footpath,parking lot,stadium, applied between the now and old asphalt.

Reinforcement: applied on the soft foundation of the unpaved road, the airport path, railroad, the landfill, the stadium, etc. to prevent the geomembrane to be punctured by the gavel.

Filtration: applied at the bottom of the landfill that penetrate, to protect the geonet and geo synthetic material, and prevent the soil to enter inside

Drainage: applied under the geomembrane,the stadium,the ballast of the railway.

3) Category: staple fiber needle punched non-woven geotextile, ect.

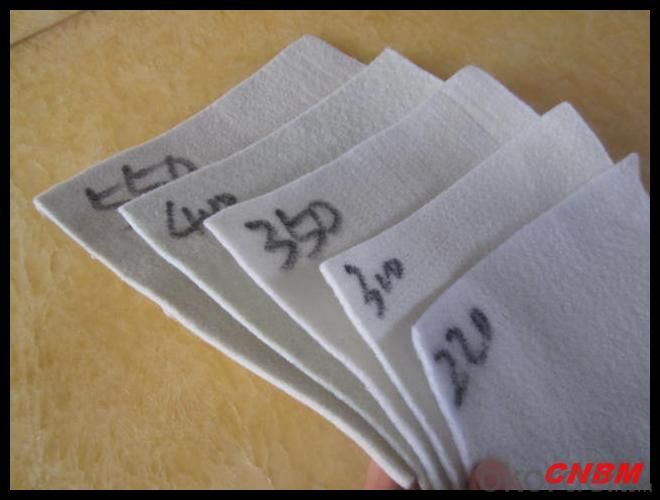

4) Width: 2-6m Mass Per Unit:80-1500g/m2

5) Specification:

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Remark | |||||||||

Deviation of mass Per Unit% | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |||||||||

Thickness,mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |||||||||

Deviation of Width,% | -0.5 | |||||||||||||||||||

Tensile Strength at Break,KN/m≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD | ||||||||

Elongation at Break,% | 25-100 | MD/CD | ||||||||||||||||||

CBR Bursting Strength,KN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |||||||||

Eos 090(090)mm | 0.07-0.20 | |||||||||||||||||||

Coefficient of Vertical Permeability,cm/s | K*(10-1-10-3) | K=1.0-9.9 | ||||||||||||||||||

Tear Strength,KN≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD | ||||||||

Detailed Images

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles commonly used in rainwater harvesting systems?

- Yes, geotextiles are commonly used in rainwater harvesting systems for filtration and separation purposes. They help prevent soil erosion, filter out debris, and ensure the quality of collected rainwater.

- Q: Are geotextiles suitable for use in wetlands?

- Yes, geotextiles are suitable for use in wetlands. They are commonly used to stabilize soil, control erosion, and promote vegetation growth in wetland areas. Geotextiles can help retain moisture, filter water, and provide support to prevent soil movement. Additionally, they are often biodegradable or made from natural materials, making them environmentally friendly and suitable for use in wetland ecosystems.

- Q: What are the different factors to consider for geotextile selection in agricultural applications?

- When selecting geotextiles for agricultural applications, several factors need to be considered. These factors include the type and level of soil erosion, the desired drainage and filtration requirements, the expected load and stress levels on the geotextile, the potential for chemical exposure, the climate and weather conditions, and the longevity and durability needed for the specific agricultural application.

- Q: Geosynthetics direct shear instrument reference standards which

- Geosynthetics Direct shear test The abrasive characteristics of the sand / geotextile interface were measured by direct shear test of the standard sand / geotextile contact surface. Test Specimens: 1. Tile the specimen on a rigid horizontal base located in the lower part of the shear box, with the front end of the specimen, and the test leads: ISO.1, GB / T.1, ASTM / D5321, JTGE50T1129, SL / T235-1999. Clamped in front of the shear zone, the sample and the base between the adhesive with adhesive, after bonding the sample should be flat, without folding and folding, the test sample and the base is not allowed between the relative slip; 2. Install the upper shear box: with the pre-quasi-quality standard sand filled with the upper shear box, the thickness of 50mm, sand thickness should be uniform, after the density of the density of 1750kg / m3; 3. Install the horizontal loader , And apply 50KPa to the sample with a reference weight of 50KPa normal pressure.

- Q: How do geotextiles aid in the filtration of water?

- Geotextiles aid in the filtration of water by acting as a barrier that allows water to pass through while trapping and filtering out sediment, dirt, and other contaminants. They help to prevent clogging and maintain the permeability of soil, improving the overall quality of water that passes through them.

- Q: What are the specifications for geotextiles used in transportation projects?

- The specifications for geotextiles used in transportation projects typically include factors such as tensile strength, puncture resistance, permeability, and durability. These specifications ensure that the geotextiles can effectively separate, reinforce, filter, or drain soil materials in transportation applications, thereby enhancing the overall performance and longevity of the projects.

- Q: How do geotextiles help with filtration in wastewater treatment systems?

- Geotextiles help with filtration in wastewater treatment systems by acting as a barrier that separates the liquid from the solid particles. They allow the water to pass through while trapping and retaining the suspended solids, sediments, and other pollutants. This enhances the treatment process by improving the efficiency of filtration and preventing clogging or blockages in the system.

- Q: How do geotextiles help in preventing soil liquefaction?

- Geotextiles help in preventing soil liquefaction by providing stability and reinforcement to the soil. They act as a barrier and restrict the movement of soil particles, thereby reducing the potential for liquefaction. Additionally, geotextiles enhance the drainage capacity of the soil, allowing water to flow through and preventing the buildup of excess pore pressure, which is a major factor leading to liquefaction.

- Q: Geotextile laying should be beyond the edge of how to set the number of specific requirements? Which specification is more detailed

- Can be more than 1 meter or so, I am specializing in the production of geotechnical materials, wish smooth

- Q: Can geotextiles be used for erosion control in coastal dunes?

- Yes, geotextiles can be used for erosion control in coastal dunes. Geotextiles are permeable fabrics that can be installed to stabilize the sand and prevent erosion by trapping sediment and promoting vegetation growth. They provide an effective and sustainable solution for protecting coastal dunes from erosion caused by wind, waves, and human activities.

Send your message to us

M200 Geotextile - Geotextile Polyester Non-Woven Fabric for Construction and Roadbed Paving

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords