SHHD automatic Solvent-free Laminating Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Characteristics

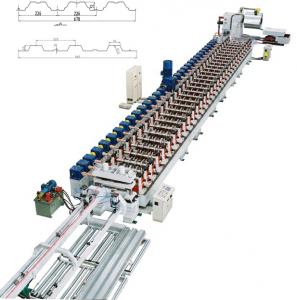

SHHD Solvent-free laminating machine adopts five rolls composite body, servo motor drive, the coating weight is controlled by roller speed difference. The Min. coating weight is 0.8-5g/㎡, the coating quantity is very precisive, and lamination is even and fast (up to 350m/min), This machine suits a variety of volatile materials, such as polyester file, polyethylene fil, polypropylene film, various types of paper, metal foil and a variety of complex film, it is also konwn as the universal compound machine.

Technical Parameters

| Model | Specification |

| Max.Web Width | 1100mm |

| Coating weight | 0.8-5g/㎡ |

| Max Machine Speed | 350m/min |

| Max Unwinding Dia. | 800mm |

| Max Rewinding Dia. | 800mm |

| Machine Drive | Servo Drives |

| Dimension(L*W*H) | 5000*2400*2900mm |

Application

SHHD Solven-free laminating machine is mainly used in food packaging, medical packaging industry.

FAQ:

1. Where is you production base located?

Our factory is located near Shanghai.

2. How many worker do we need?

Our machinery is fully automatic, so only few worker needed.

3. What kinds of base materials can be used in your machine?

please refer to main characteristic.

- Q: What is the roll forming machine?

- And said slider is provided in a slider seat with a dovetail groove structure in the lower part thereof to form a sliding mechanism; said slider block is connected with the main shaft by a taper sleeve method, The disk is fixed by bolts on a fixed plate with two elongated screw holes, one end of which is bolted to the slider and the other end abuts against the mold plate.

- Q: How is the molding machine installed?

- 1 check the machine in the transport process is damaged or deformation;

- Q: How to maintain the molding machine?

- 4 prohibits vibrator no-load operation;

Send your message to us

SHHD automatic Solvent-free Laminating Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches