SHHD-200B Auto Matic Hot Melt Coating Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Characteristics

Operating the machine is simple and automatic.

It adopts weear-resisting alloy steel coating head,make a good progress in coating precision and service lift.

It adopts overall horizontal moving coating adjusting holder, high precision at repeated lacation.

It had automatic tracking and display, storage function to glue weight, makes the operation and use convenient and quick

The first unwinding is fixed with rectification deivce, high-performance infrared sensor and electric controller ensure the didiness of substrate.

The heating temperature all controlled by PLC.

The glue supply of metering pump is automatically calculated by the coating width and glue supply weight entered by the operator, and can change the glue supply weight according to the characteristic curve of the metering pump.

With automatic stop location function when the unwinding without material.

With automatic energent stop the machine function when run out of material

Technical Parameters

| Coating Weight | 100-300g/m2 |

| Coating Speed | 3-30m/min |

| Dia. Unwinding | ≤1000m |

| Dia. Rewinding | ≤1000m |

| Coating width of the roll | 2200mm |

| Effective coating width | 2000mm |

| Installed Power | About 95KW |

| Power | 380V±15% |

| Dimension (L*W*H) | 3800*3000*2600mm |

Application

SHHD-200D hot melt coating machine is mainly applied for coating auto floor leather with hot melt pressure sensitive ahdesive and Gration bottom paper. It can also coating paper, non-woven, and leather.

FAQ:

1.is the machine speed fixed?

SHHD-200D machine speed is adjustable between 3-30m/min

2.How many years for guarantee?

We offer you 1 years guarantee

3.Do we need many workers for running machine?

it is necessary, the machine is auto-matic.

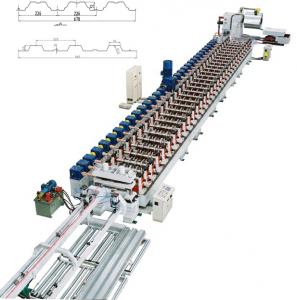

- Q: What is the roll forming machine?

- And said slider is provided in a slider seat with a dovetail groove structure in the lower part thereof to form a sliding mechanism; said slider block is connected with the main shaft by a taper sleeve method, The disk is fixed by bolts on a fixed plate with two elongated screw holes, one end of which is bolted to the slider and the other end abuts against the mold plate.

- Q: How is the molding machine installed?

- Factory QTJ4-25 block forming machine have been in accordance with the relevant provisions of the factory have done the factory test, but due to long-distance transport and a long time to place and other reasons, the installation should be the following checks:

- Q: How to maintain the molding machine?

- 5 After the end of the work every day, the various parts of the machine should be in the initial state and thoroughly clean the various parts of the machinery to prevent concrete in the mechanical condensation, but not water washing machine;

Send your message to us

SHHD-200B Auto Matic Hot Melt Coating Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches