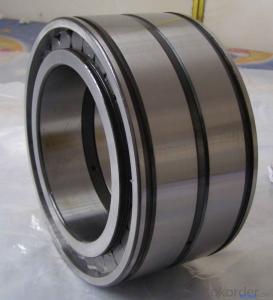

self-lubricated sliding bearing with high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

self-lubricated sliding bearing

1, low wear, low friction , with long life

2,low vibration, low noise and non-pollution

self-lubricated sliding bearing

Material

1.PTFE with fibre 0.01~0.03mm

2.Porous bronze 0.2~0.3mm

3.Steel backing 0.7~2.3mm

4.Tin-plating 0.005mm or copper plating 0.008mm

Technical

Load capacity 140N/mm2

Temperature -195°C ~ +280°C

Speed limit 5m/s

Friction coef(u) 0.04~0.20

PV Limit(Dry) 3.6N/mm2 .m/s

Application

1.PTFE and fibre can protect the shaft while in operation.

2.It is suitable for the machine required harmless to people because

of Lead-free.

3.Goodload capacity and anti-wear.

4.Bronze and steel have good thermal conductivity.

5.Anti-corrosion because of surface plating.

6.It is widely used in general machines,and suitable for food machine,pharmaceutical

machine,tobacco machine etc.It will subsitute SF-1 series bushings in future because of environment protection.

- Q: On what occasions are plain bearings used?

- 1, the working speed is very high;2, requirements of the axis support particularly accurate occasions;

- Q: Sliding bearing is a kind of friction bearing, according to its friction state can be divided into what?

- The friction resistance of rolling bearings is small, and the load, rotation speed and work temperature are suitable for a wide range, and the standard partsA large number of special manufacturers, reliable quality, adequate supply, lubrication and maintenance convenience, but larger radial size, vibration and noise.As the mechanical efficiency of rolling bearings is higher, the maintenance of bearings is lower, so it is widely used in middle and low speed, as well as high precision requirements.

- Q: Which sliding bearing materials are free of lubrication?

- The sliding bearing material can be lubricated without self-lubricating bearings. It is made of 4 layersA mixture of 1. PTFE and fiber 0.01~0.03mm can form a very good transfer film to protect the grinding shaft, providing the self-lubricating properties of the bearings.2. copper powder layer 0.20~0.35mm, with good bearing capacity and wear resistance, good thermal conductivity, can timely transfer the heat generated during the operation of bearings. The composite can be infiltrated into the gap of copper powder balls, and the bonding strength is improved.

- Q: What does "SK195" mean?

- The oil film also has a certain vibration absorption capacity. But the starting friction resistance is larger. The shaft supported by the bearing is called the journal, and the part that matches the journal is called the bush. In order to improve the friction properties of the bearing surface, the antifriction material layer, which is cast on its inner surface, is called the bearing lining.

- Q: What are the two types of friction lubrication in plain bearings?

- (2) the bearing material and the bush structure have a great influence on the performance of the sliding bearing. The bearing material and the bush structure should be selected by considering various factors.

- Q: How many times does the clearance of the sliding bearing take the diameter of the axle?

- for example: grinder and lathe dividing head main bearing with the accuracy of H7/g6, agricultural machinery bearings with accuracy of H11/d11.

- Q: The study on the friction and wear behavior of thrust bearings under oil lubrication conditions at home and abroad, their significance and future prospects!!!! The best reference source. Thank you if there are similar can be sent to my mailbox.

- Thrust sliding bearing: a sliding bearing that bears axial thrust and restricts axial movement of the shaft. Two, the friction surface is completely separated by the fluid film thrust bearings, divided into fluid dynamic thrust bearings and hydrostatic thrust bearings, suitable for high speed operation. Two a thrust bearing whose surface is not completely separated by a fluid film operates under boundary lubrication and is only suitable for low speed operation.

- Q: The difference between rolling bearings and plain bearings in ball mill

- You should ask, why does the mill's bearings change from sliding to rolling?. The moment of technological upgrading in industry is the birth of new products. As you ask, when the ball mill starts to use the bearings is like asking when the bike starts to use chain drive. The design, I have not been able to know the mill but the historical setting, must have tried many times of failure, material, loading, production process, and ultimately determine the early embryonic development since the various types of mill.

- Q: What are the causes of high temperature of plain bearings?

- What is the actual temperature? The bearing tells the rotating part, and the more than 100 degree is normal

- Q: What are the implications of limiting P and PV for non full liquid sliding bearings, please?

- But the influence factors of the boundary film is very complex, the simplified calculation formula of conditional.Radial sliding bearing1, limiting average specific pressure PObjective: to avoid the excessive extrusion of the lubricating oil under the action of loading, and to limit the excessive wear of the bearing.

Send your message to us

self-lubricated sliding bearing with high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords