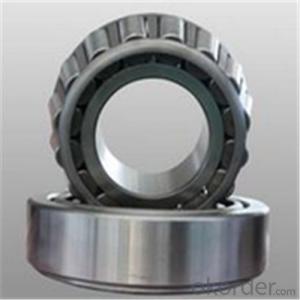

Cylindrical Roller Bearing Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cylindrical Roller Bearing

Description

Cylindrical roller bearings have no ribs on either the inner or outer ring, so therings can move axially relative to each other. These can be used as free-end bearings. Cylindrical roller bearings, in which either the inner or outer rings has two ribs and the other ring has one, are capable of taking some axial load in one direction Double-row cylindrical roller bearings have high radial rigidity and are used primarily for precision machine tools.Cylindrical roller bearings are available in many designs, series and sizes. The majority are single row bearings with a cage. High-capacity bearings, single and double row full complement bearings (without a cage) complete the international standard assortment listed.

Features

1.) Offers a complete range, both metric and inch sizes available in metric and

imperial bore sizes ranging from 12 to 1320 mm.

2.)High radial load capacity - making cylindrical roller bearings suitable for high

speed applications.

3.)Designs - designated NU, NJ, NUP, N or NF for single row bearings and NNU or

NN for double row types, defines the bearing ring rib configuration.

4.) Cages - Available with pressed steel, machined brass and polyamide cages

throughout the range.

5.) Special designs - manufactures a range of four-row cylindrical roller bearings,

primarily designed for use as steel mill roll-neck bearings.

6.)Bearings are also available with both lubrication holes and a machined

lubrication groove on the outside surface of the outer ring.

Application of cylindrical roller bearings:

Cylindrical roller bearings are used in a variety of applications. Examples include mining, petroleum production, power generation, power transmission, cement processing, aggregate crushing, and metal recycling. Some cylindrical roller bearings are used in briquetting machines, rubber mixing equipment, rolling mills, rotary dryers, or pulp and paper machinery. Others are used in construction equipment, crushers, electric motors, blowers and fans, gears and drives, plastics machinery, machine tools and traction motors and pumps.

F&Q

Q:How long es cycle of bearing life?

A:According to international standards, at least a year and a half , up tu 2 years

Q:How to maintenance bearing

A:Add to lubricantes on time

Q:Have diagram for bearing

- Q: KOYO cylindrical roller bearings, //KOYO cylindrical roller bearings, how to determine the accuracy level?

- The processing of the mating surface, especially the mating surface, is not done in a single clamping. The use of the bearing seat also causes misalignment, such as a flange bearing seat or a vertical KOYO inlet bearing block. As the work load causes the shaft to bend and deform, and also causes the inner and outer ring of the bearing to tilt, it will also appear misalignment.The main products are: KOYO bearing rolling bearing, deep groove ball bearings, high precision bearings, self-aligning bearings, bearings, plane ball bearings, cylindrical roller bearing, linear guide bearing, ball screw bearings, miniature linear guide bearing, cross roller guide bearings, reciprocating rotary bearings, ball bearing slide bushing, group cam follower.

- Q: Double row full cylindrical roller bearings, NNCF5008 installation, we need to pay attention to the direction of it?

- Double row cylindrical roller bearings have no directionality, so they do not need to pay attention to the direction! However, it should be noted that the inner ring and outer ring should be positioned separately to prevent axial movement!

- Q: Can the Nu and N type NJ NUP cylindrical roller bearings bear axial force?

- The answer upstairs is clear. Such bearings can not be designed with axial force. In use, the inner and outer rings of the bearing can have larger axial displacement, and the aim is to compensate the length change caused by the rotating part of the two bearing due to the temperature rise.

- Q: In the car there is a cylindrical roller, the size of the diameter of 25mm, the outer diameter of 32mm, width of 9.5mm, who knows what the standard size, have direct purchase Mody, thank you!

- There is some doubt about your description. According to your internal diameter and external diameter, if the cylindrical roller bearings, the scroll is quite small. I don't see much of this kind of cylindrical roller bearing. Do you mean needle roller bearings? If needle roller bearings can be found, and HK2514/18 RS similar models.

- Q: What is the limit speed and rated dynamic load of NSK full M40-19g cylindrical roller bearings, HTF?

- D - tapered roller bearings with a contact angle of 28 degrees. C, CA (with solid brass cage), CD (with stamping cage), spherical roller bearing with high load. E -- high load cylindrical roller bearing. H - thrust roller bearing high load. J - tapered roller bearings of the outer raceway, the small end diameter, angle, outer ring width is consistent with the provisions of ISO. (2) material G - ring, rolling body is carburizing steel. H - ring, roll for stainless steel. (3) holder M - copper alloy solid cage. T - synthetic resin cage. W - press holder. V - no cage. (4) sealing ring, dust cover Z, ZS - one side with steel plate dust cover. ZZ, ZZS -- dust cover for two side steel plate. D, DU - one side contact rubber ring. DD, DDU -- two faced contact rubber ring. V - one with a non-contact rubber ring. VV -- two side non-contact rubber sealing ring. (5) ring shape K - taper hole, taper 1:12. K30 -- taper hole, taper 1:30. E - there is a notch or oil hole in the ring. E4 - oil tank with oil holes on the outer ring. N -- outside outer diameter band stop groove. NR -- outer ring, outer band, stop groove, stop ring.

- Q: Attention problems of cylindrical roller bearings

- 4, when the interference is large, the oil bath heating or inductor heating bearings can be used to install the heating temperature range of 80 degrees -100 DEG C, the maximum can not exceed 120 degrees centigrade. At the same time, the nut or other appropriate method is used to fasten the bearing so as to prevent the contraction of the bearing in the direction of width and to create a gap between the collar and the shaft shoulder. 5, single row tapered roller bearings installed, the final adjustment should be clearance. The clearance value shall be determined according to the working conditions and the magnitude of the interference fit. Test shall be carried out when necessary. Double row tapered roller bearings and pump shaft bearings have been adjusted for clearance at the factory, and no adjustment is necessary during installation. 6, the bearing should be installed after the rotation test, the first for the rotary shaft or bearing box, without exception, then the power for no load, low speed operation, and then gradually increase as the functioning of the rotation speed and load, and to detect noise, vibration and temperature, abnormal, should stop running and check. The running test is normal and can be used before delivery.

- Q: What is the maximum rotational speed of a single row full cylindrical roller bearing?

- FAG single row full cylindrical roller bearingsFAG single row full cylindrical roller bearings can bear large radial loads, and can also bear single direction axial load. Axial positioning can be guaranteed by a symmetrical arrangement of similar bearings. NCF, 29V, NCF, 30V series of bearings have two fixed inner ring, the outer ring has a baffle, they can only bear the direction of the outer edge of the fixed axial load. The NJ23VH series bearings can bear the axial load toward the inside of the inner ring, and their rollers are fixed in the outer ring, even if the inner ring is taken away. The two rings are tight fit, easy installation and disassembly.

- Q: Why cylindrical roller bearings can not bear axial load?.

- Bearing bearing axial force or radial force is determined by the structure of the bearing, thrust ball bearings are also called plane bearings, which are mainly used to bear axial force; cylindrical roller bearings can bear radial forces and are not suitable to bear axial force.

- Q: How to calculate the clearance of bearings, such as 23226 double row cylindrical roller bearings

- 1, radial clearance: non preload, bearing radial load, the radial clearance of G for any angle along the radial direction, in the absence of external load relative to the outer ring inner ring from a radial eccentric limit position, move to the opposite limit position of the radial distance arithmetic mean.2, axial clearance: non preload, bearing can withstand axial load in two directions, the axial internal clearance of G: without external load, a ring relative to the other ring, from an axial limit position toward the average axial distance limit position opposite the.

- Q: Thrust cylindrical roller bearings, the main use?

- Thrust cylindrical roller bearings, the main use? Thrust cylindrical roller bearings are mainly used in oil rigs, iron, steel, machinery and so on. Our factory uses the bearings of Changzhou Enke Bearing Co., Ltd., they have many kinds of bearings and meet various demands.

Send your message to us

Cylindrical Roller Bearing Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords