7018 Angular contact ball bearings Bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sepcification:

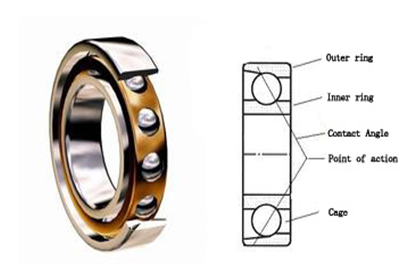

Angular contact ball bearings can bear radial load and axial load at the same time and also can bear pure axial load. Their ability of axial load is determined by contact angle and is increased with contact angle increasing; speed limit is higher; stiffness is big and can be pre-adjusted. They are applicable to high-speed and high-precision site.

Product application:

- spindle and other high speed precision mechanical spindle

- aircraft engine spindle

- high frequency motor

- printing machinery

- air compressor

- gas turbine

- jet engines

- turbines

-pump

| Design ations | Principal dimensions (mm) | 〆15º | 〆25º | ||||

| Limit speed | Limit speed | ||||||

| d | D | B | Basic load rating | Lubrication | Rated load | Lubrication | |

| Cr Cor | Grease Oil | Cr Cor | Grease Oil | ||||

| 70 Series single angular contact ball bearings | |||||||

| 7003 | 17 | 35 | 10 | 6.7 4.9 | 44000 66000 | 6.4 4.7 | 39000 59000 |

| 7004 | 20 | 42 | 12 | 9.6 6.3 | 37000 55000 | 9.2 6.0 | 33000 49000 |

| 7005 | 25 | 47 | 12 | 12.9 8.7 | 33000 49000 | 12.3 | 29000 44000 |

| 7006 | 30 | 55 | 13 | 15.7 11.6 | 27000 42000 | 14.9 10.9 | 23000 37000 |

| 7007 | 35 | 62 | 14 | 19.3 17.5 | 19000 33000 | 10.4 10.3 | 19000 33000 |

| 7008 | 40 | 68 | 15 | 19.9 19.1 | 18000 31000 | 18.9 18.2 | 16000 27000 |

| 7009 | 45 | 75 | 16 | 26.7 25.3 | 16000 27000 | 25.4 24.1 | 15000 25000 |

| 7010 | 50 | 80 | 16 | 27.6 27.5 | 15000 25000 | 26.2 26.2 | 14000 23000 |

| 7011 | 55 | 90 | 18 | 36.7 37.1 | 13000 21000 | 34.8 35.3 | 12000 19000 |

| 7012 | 60 | 95 | 18 | 37.8 | 13000 21000 | 35.8 38.0 | 11000 18000 |

| 7013 | 65 | 100 | 18 | 38.9 42.9 | 12000 19000 | 36.8 40.7 | 10000 17000 |

| 7014 | 70 | 110 | 20 | 49.9 55.5 | 11000 18000 | 47.2 52.7 | 9000 16000 |

| 7015 | 75 | 115 | 20 | 51.3 59.2 | 10000 17000 | 48.5 56.2 | 8500 15000 |

| 7016 | 80 | 125 | 22 | 61.6 70.4 | 9000 16000 | 58.3 66.9 | 8000 14000 |

| 7017 | 85 | 130 | 22 | 63.6 | 8500 15000 | 59.9 71.3 | 7500 13000 |

| 7018 | 90 | 140 | 24 | 66.9 | 8000 14000 | 63.2 79.7 | 7000 12000 |

| 7019 | 95 | 145 | 24 | 79.1 97.6 | 7500 13000 | 74.8 | 6500 11000 |

| 7020 | 100 | 150 | 24 | 81.2 103.3 | 7000 12000 | 76.7 | 6000 10000 |

| 7021 | 105 | 160 | 26 | 93.9 118.2 | 6500 11000 | 88.8 | 6000 10000 |

| 7022 | 110 | 170 | 28 | 110.4 139.8 | 6000 10000 | 104.4 132.8 | 5700 9000 |

| 7024 | 120 | 180 | 28 | 112.7 148.7 | 6000 10000 | 106.3 141.1 | 5700 9000 |

| 7026 | 130 | 200 | 33 | 144.8 190.8 | 5700 9000 | 136.8 181.0 | 5000 8000 |

| 7028 | 140 | 210 | 33 | 148.7 202.6 | 5000 8000 | 140.4 192.2 | 4600 7500 |

| 7030 | 150 | 225 | 35 | 168.4 232.5 | 4600 7500 | 159.1 220.6 | 4000 6500 |

| 7032 | 160 | 240 | 38 | 189.1 264.5 | 4000 6500 | 178.6 251.0 | 3800 6000 |

| 7034 | 170 | 260 | 42 | 205.6 299.3 | 3800 6000 | 194.2 284.0 | 3300 5300 |

| 7036 | 180 | 280 | 46 | 229.5 352.1 | 3500 5700 | 216.8 334.1 | 3000 5000 |

- Q: What does angle contact back to back mean?

- Two bearing by webbing webbing. (face is once again thick, thin again)

- Q: Angular contact ball bearings, how to judge the size of the mouth?

- Yes, look at the outer ring of the bearing. The thinner end is the big one.

- Q: What does angular contact ball bearing 70216AC mean?

- 7--- angular contact ball bearing0--- normal width series2--- diameter series code, which means light series16--- internal diameter code indicating the inner diameter of 16*5=80mmAC--- internal structure code indicating the nominal contact angle of angular contact bearing is 25 degrees

- Q: The difference between ultra high speed angular contact ball bearings and other plain bearings

- The ability to bear the axial force of angular contact ball bearings than ordinary high speed ball bearings, angular contact ball bearing is slightly lower than the ordinary ball bearings of the same type.

- Q: What are the reasons for the use of tapered roller bearings and angular contact ball bearings?

- Selection of bearings in accordance with the theory and practice of judgment, that is, bearing capacity and the form of movement and load factors are different. That is, the role of the two bearings

- Q: Two angular contact ball bearings, the use of clearance problems

- The installation form is DB, and the inner ring preload is adjusted. For example, by adjusting the nut of the lock inner ring, tighten the force adjustment. Generally selected bearings, manufacturers have been conscious of the inner ring and outer ring thickness is not the same, that is, as long as locking the inner ring, the force is the factory set the amount of preload.

- Q: How many angles are there in angular contact ball bearings? How many degrees are they?

- A stands for 30 degrees, A5 stands for 25 degrees, B stands for 40 degrees, and C stands for 15 degreesThe new Seiko NSK serves you!

- Q: How can angular contact be distinguished from the front and back? What are the characteristics of each?

- Hello, there is a number on the front, no number on the back

- Q: Do angular contact ball bearings come with a sealing cap?

- Angular contact ball bearings generally have no dust caps or seals. You can design and install an oil seal or something like that.In general, deep groove ball bearings are lubricated with dust cover. Angular contact ball games are generally lubricated with lubricating oil, without dust cover, such as grease lubrication, the effect is poor.

- Q: Is there a way to calculate the axial force of angular contact ball bearings?

- This is the first response to the landlord, you can count, here introduces the concept of equivalent static load, a static equivalent radial load P0a (subscript 0A), a static equivalent axial load P0a (subscript 0A), and a static safety factor FS, we first check the static C0 7202AC (0 Department of AC, should represent the subscript) is the contact angle is 25 degrees, SKF C0 4800N, personally think that this value is too conservative, according to P0a=2.3*Fr*tg25+Fa (Fr is bearing radial load, axial load bearing is Fa, tg25 is the tangent, contact angle of 25 degrees according to the contact angle vary) and FS (fs=C0/P0) is greater than 1.5, launched: P0a less than 3200N, 1.07Fr+Fa less than 3200N that is to say, add up to force multiplied by the coefficient two component bearings, can not exceed this number. If only the axial force, the axial force is Fr=0, maximum 3200N can finally add a few points, FS safety coefficient is adjusted according to the condition, some places may be less than 1, and the place that cannot be less than 1.5, not less than 3, do not understand, temporarily by not less than 1.5. Also hope to help add master. And then there's the C0. Every brand might have a small difference. Here's SKF. So, if you calculate it in theory, you're going to make it smaller

Send your message to us

7018 Angular contact ball bearings Bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords