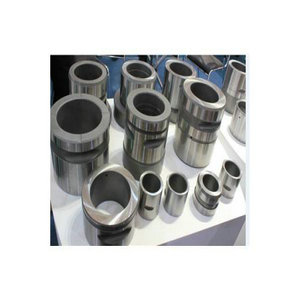

Hydraulic Cylinder bushing of chinese manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Hydraulic Cylinder bushing (SF-1D)

1.steel backing,sintered porous bronze,PTFE layer

2.oilless,self-lubricating

3.low wear

Hydraulic Cylinder bushing (SF-1D) introduction:

1. Hydraulic special bearings is a new type op material, which in basis of SF-1P and designed in principles of oil and shock absorber. it become more wear-resisting under breaking off the lubricating oil .these products also particularly suitable for the frequent reciprocating motion besides having the advantages of SF-1P.

2. Its properties is similar to that of the foreign product designated as DP4,Currently the product gradually replace SF-1P,applying to auto shock absorber, hydraulic cylinders and other various fields.

Load capacity 120N/mm2

Max Speed 2m/s

Friction Coefficient 0.04~0.20

PV Limit (dry) 3.6N/mm2 m/s

PV Limti (oil) 50N/mm2 m/s

Temperature Limit -195oC ~+270oC

Why use Cast brass Bearing?

long service life and maintenance-free

High load capacity

High wear resistence

low coefficients of friction

Good heat conductivity

High corrosion resistence

- Q: Maintenance method of plain bearing

- The repair method is wrong and the installation is wrong. Use improper maintenance, quality control is not strict, 1, cleaning the shaft neck, oil circuit, oil filter, and replace the clean quality requirements of the lubricating oil2, with the repair after scraping the bush or new bush3, if found wrong installation, should be timely find4, pay attention to maintenance qualityBecause of the unreasonable structure of cavitation bearing (bearing on the oil is not reasonable, the shaft vibration), steam bubble formation of oil film bearing, steam bubble rupture, local surface creates a vacuum caused by small spalling cave erosion damage 1, increase the supply pressure2, improve the shape of the oil groove and groove, modify the edge or shape of the groove to improve the shape of the oil film streamline3, reduce the bearing clearance, reduce axle sway4, change the more suitable bush materialElectric erosion due to insulation is not good or bad ground, or static electricity, a certain voltage is formed between the shaft and bearing, penetrating the oil film between the shaft and bearing the spark, the insulation of the bearing into Pit 1, check the machine, special attention should be paid to some protective devices (such as heat resistance thermocouple wires are well insulated)2. Check the grounding of the machine3, if the damage after electrical erosion is not too serious, you can scrape the bearing4, check the journal, if the shaft on the electric erosion pit, should be polished shaft neck, remove the pit

- Q: Sliding bearings relative clearance 0.001 what?

- The so-called relative clearance, refers to the sliding bearings of the Bush and bushings, nominal size tolerances can be large or small, but the gap between each other can only be 0.001.

- Q: Explanation of sliding bearing code: 6309-2z/p5

- This is deep groove ball bearing.6 deep groove ball bearings3 wide range09 represents the bearing inner diameter: 45mm2Z is flanked by iron dust capsP5 is the precision grade: the dimension rotation accuracy conforms to the ISO5 class tolerance

- Q: What is the bearing force value, how to determine, how to adjust, what is the effect?

- Bearing preload value of the end is lower level put a root diameter of 1mm length 100mm wire (A1, A2), motor or pump mechanical corresponding middle bearing upper same diameter and length of wire (B1), and then fasten the bearing shell and lid, with a screw tightening, then open remove the flat wire, so the bearing force value of s=b1- (a1+a2) /2, mm.

- Q: The oil release ring is in the mounting position of the sliding bearing

- The axial force is required to be transmitted to the base, and the axis is rotating or the axial forces that are transmitted vary.

- Q: When the sliding bearing works, does the Bush not rotate and the journal rotates?

- Generally, the Bush and the bearing seat are relatively fixed, and the shaft rotates; also, the shaft is fixed and the Bush rotates.In fact, it is essentially the same, that is, that one component rotates relative to the other.

- Q: How to choose the aspect ratio of plain journal bearings

- The discharge capacity at the end of the shaft is large, the power consumption is small, and the temperature rise of the oil is lower, but the bearing capacity of the bearing is reduced.

- Q: Why does the sliding bearing use clearance fit?

- The shaft should be rotated inside the sliding bearing without the clearance fit.

- Q: For sliding bearing, bearings, bushings, bushing and difference function

- The bushing is mounted on the shaft, with the shaft to rotate together. The Bush is mounted on the seat and does not rotate.There are many large shaft to achieve part of high hardness and high wear resistance with the invention and bearing bushes, but since a high frequency quenching and surface treatment process after these basically eliminated.

- Q: What are plain bearings, roller bearings, roller bearings, needle roller bearings?

- A rolling bearing (ROLLINGBEARING) is a precision mechanical element that reduces the friction loss between a running shaft and an axle seat to a rolling friction. Generally, the rolling bearings consist of the outer ring, inner ring, roller and cage. A type of bearing in which the journal rotates in a circular contact with a number of rollers usually mounted on the locating ring.

Send your message to us

Hydraulic Cylinder bushing of chinese manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords